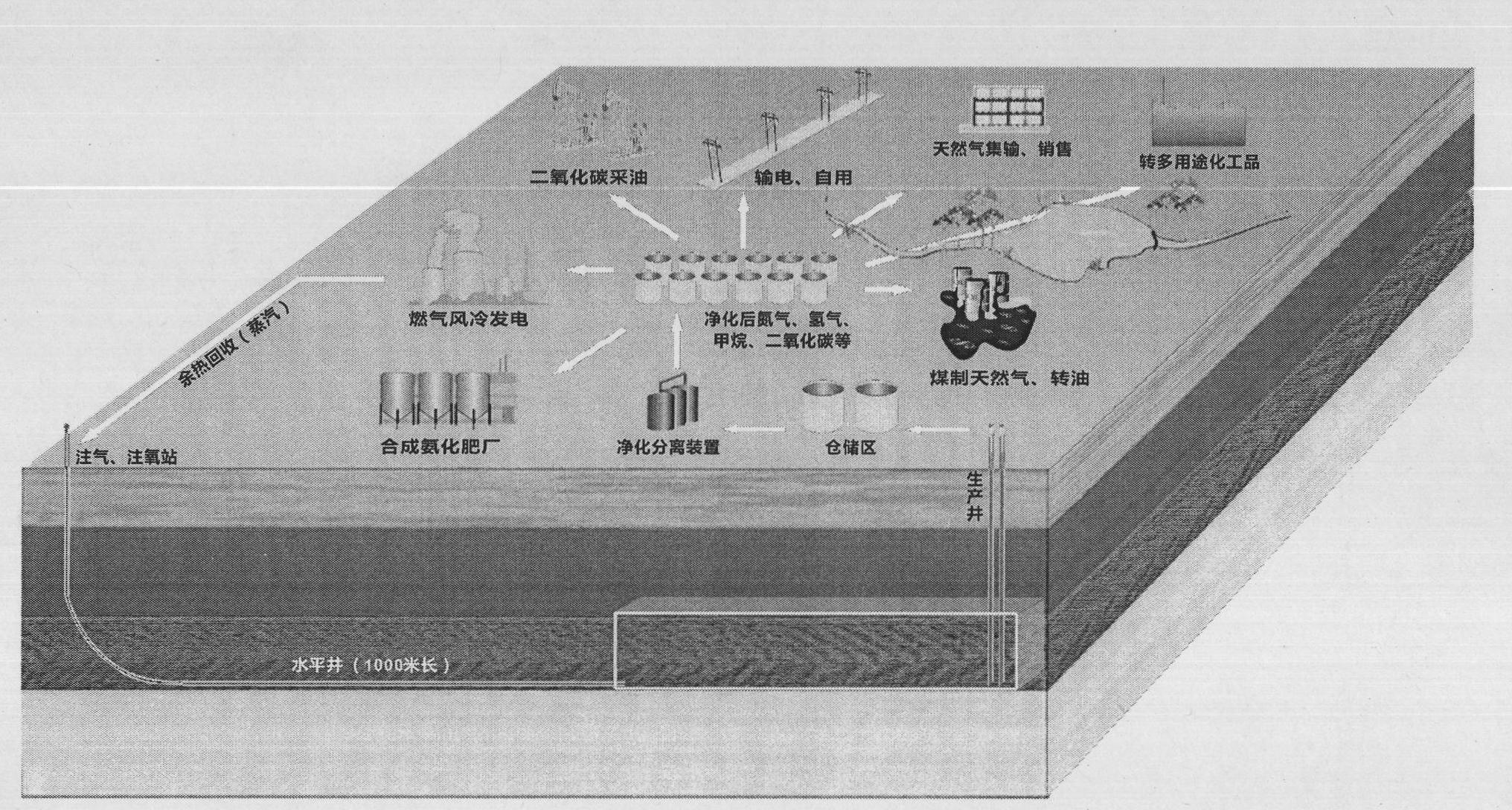

Underground coal gasification poly-generation closed operation technology

An underground gasification and polygeneration technology, which is applied in coal gasification, underground mining, mining fluids, etc., can solve problems such as lack of deep coal underground gasification technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0005] The present invention is further described below: Underground coal gasification can be zero-emission cutting-edge environmental protection green technology: it is a zero-emission technology that injects compounds into underground coal seams through water vapor through underground coal gasification through polygeneration engineering technology, wherein: horizontal wells Gas injection, oxygen enrichment, combustion aid, separation and purification of crude gas produced by combustion, heat value methane waste heat power generation, hydrogen and nitrogen to produce synthetic ammonia, clean coal gas to produce natural gas, multi-purpose coal chemical products, especially the production of coal-to-oil and fuel products, etc. It is the best purpose for underground coal gasification; waste heat recovery compound is injected into the gasified coal seam for combustion and hydrogen generation after steam power generation, and can produce 20% hydrogen at the same time to produce clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com