Epoxy mesoporous molecular sieve for use in bio-enzyme immobilization and preparation method thereof

An epoxy-based mesoporous and mesoporous molecular sieve technology, which is applied in the direction of being fixed on or in an inorganic carrier, can solve the problems of loss of catalytic activity of free enzymes, and achieve the effects of improving operational stability, performance and activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

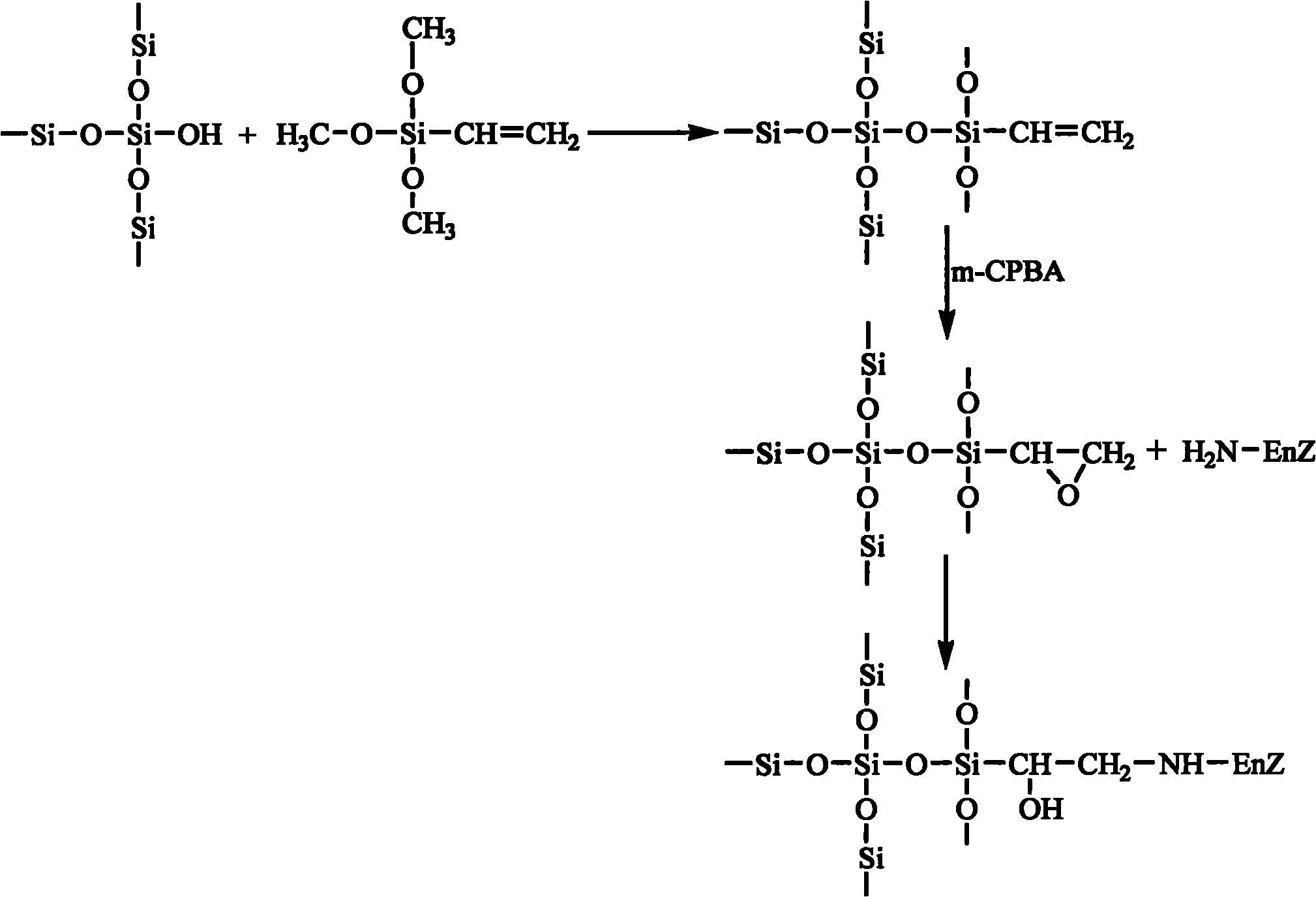

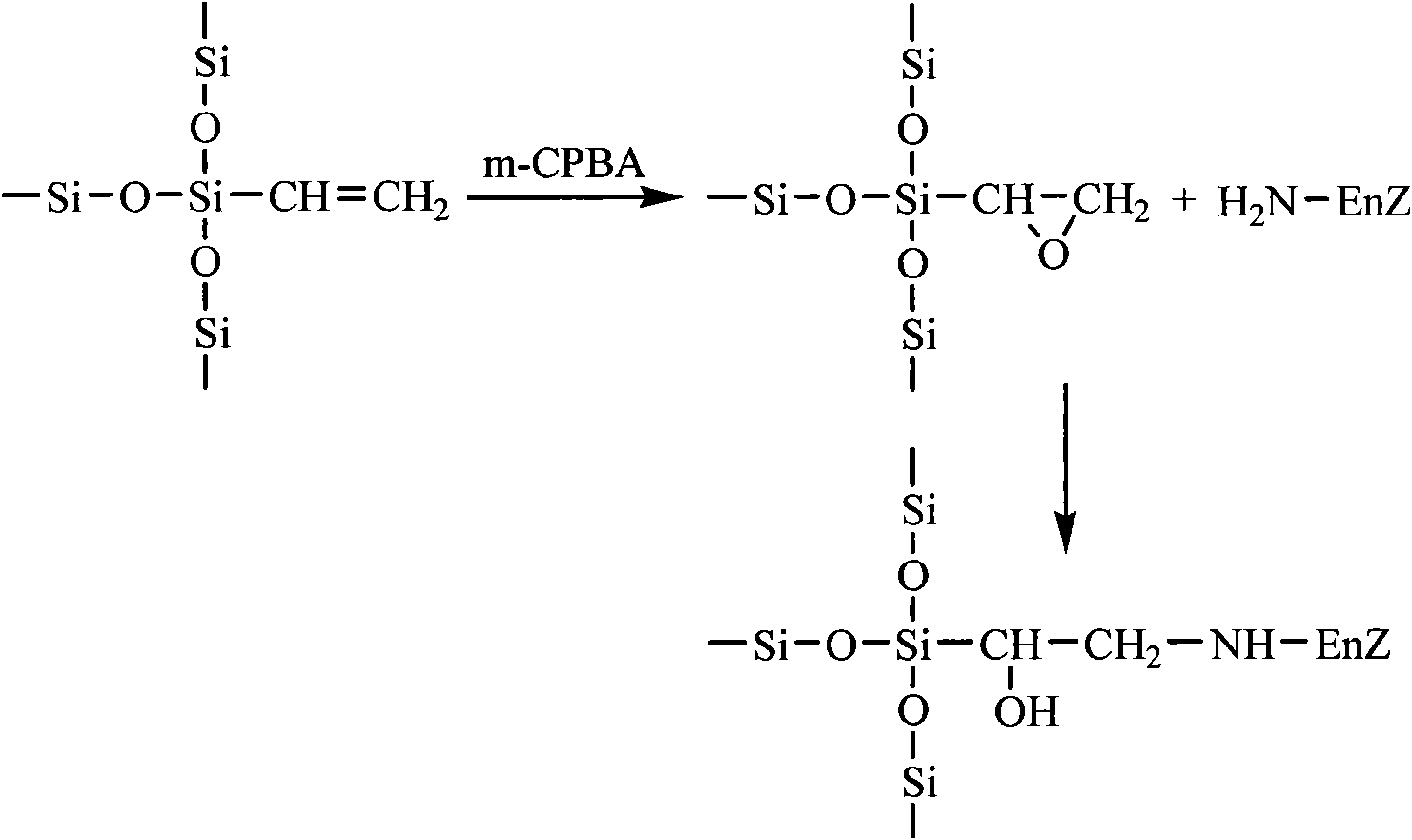

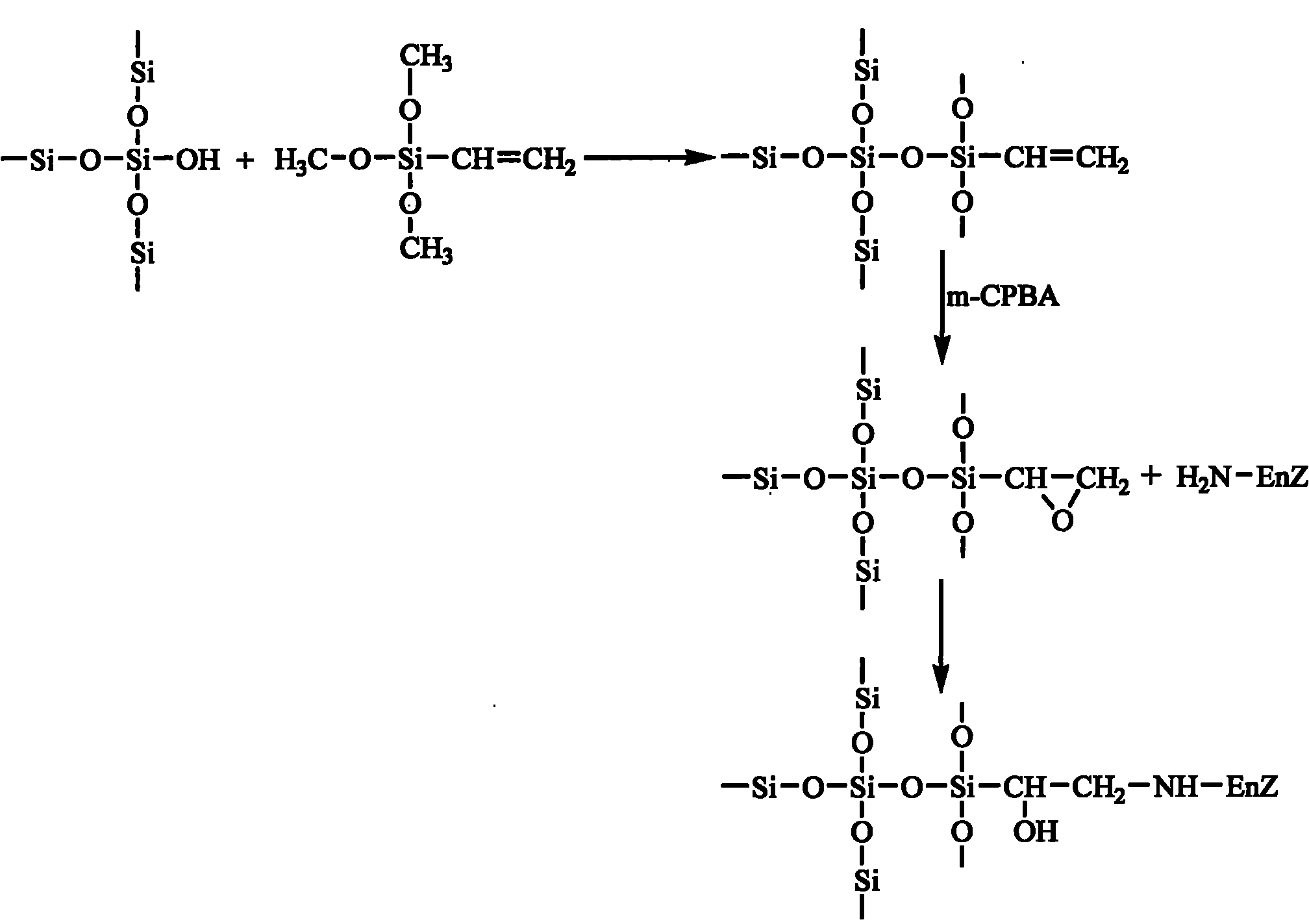

[0035] Schematic diagram of the functionalization of epoxy groups on the surface of mesoporous molecular sieves and the immobilization of enzymes with vinyltrimethoxysilane and m-CPBA. figure 1 As shown, at room temperature, 5.68g Pluronic P123 (EO 20 PO 70 EO 20 ,M av =5800) and 11.36gNa 2 SO 4 Dissolve in 160mL of 1.0mol / L HCl solution; after complete dissolution, raise the temperature of the solution to 35°C and keep stirring for several hours, slowly add 53.2mmol of tetraethyl orthosilicate (TEOS) and vinyltriethoxy A mixture of silane (TEVS) (the molar percentage of TEVS is 5%), and kept stirring at 35°C for 20 hours; the solution was transferred to a hydrothermal crystallization kettle with a polytetrafluoroethylene liner, and placed in Crystallize in an oven at 100°C for 24 hours, then cool the solution to room temperature and filter the obtained solid, and dry it in an oven at 100°C overnight; put 1.0 g of mesoporous molecular sieves without template removal in a ...

Embodiment 2

[0038] The molar percentage of TEVS in embodiment 1 is changed from 5% to 10%, other conditions are the same as embodiment 1, obtain epoxy-based mesoporous molecular sieve, be used for the immobilization of penicillin acylase, the immobilized enzyme activity that obtains is 2262U / g, after 10 cycles of use, the immobilized enzyme retained 80% of its initial activity.

Embodiment 3

[0040] Change the molar percentage of TEVS in Example 1 from 5% to 15%, and other conditions are the same as in Example 1 to obtain epoxy-based mesoporous molecular sieves, which are used for the immobilization of penicillin acylase, and the immobilized enzyme activity obtained is 1563U / g, after 10 cycles of use, the immobilized enzyme retained 66% of its initial activity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com