Method for extracting and separating coixenolide and coix seed oil step-by-step by using supercritical CO2

A technology of coix seed oil and coix seed ester, applied in chemical instruments and methods, carboxylate preparation, fat oil/fat production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A supercritical CO 2 A method for step-by-step extraction and separation of coixenolide and coix seed oil, comprising the following steps:

[0019] 1) Grinding and granulating: Grind the coix seed that has been shelled and removed impurities into a fine powder of 60-200 mesh, pour it into a blender, add pure water accounting for 40%-80% of the raw material weight while stirring, and use 20 mesh Sieve for wet granulation, dry at 55-60°C, and control the moisture within 5%;

[0020] 2) Grain sifting: the dried coix seed granules are sieved with a 10--20 mesh sieve, then the fine powder is sieved out with a 50 mesh sieve, and the sieved fine powder is returned to re-granulate;

[0021] 3) Supercritical CO 2 Step-by-step extraction and segmented collection: carbon dioxide cylinder 1, carbon dioxide storage tank 2, extraction kettle 3, and separation kettle 4 are connected in sequence, and there is a pipeline 6 above it for CO 2 coix seed oil and coix seed ester, carbon d...

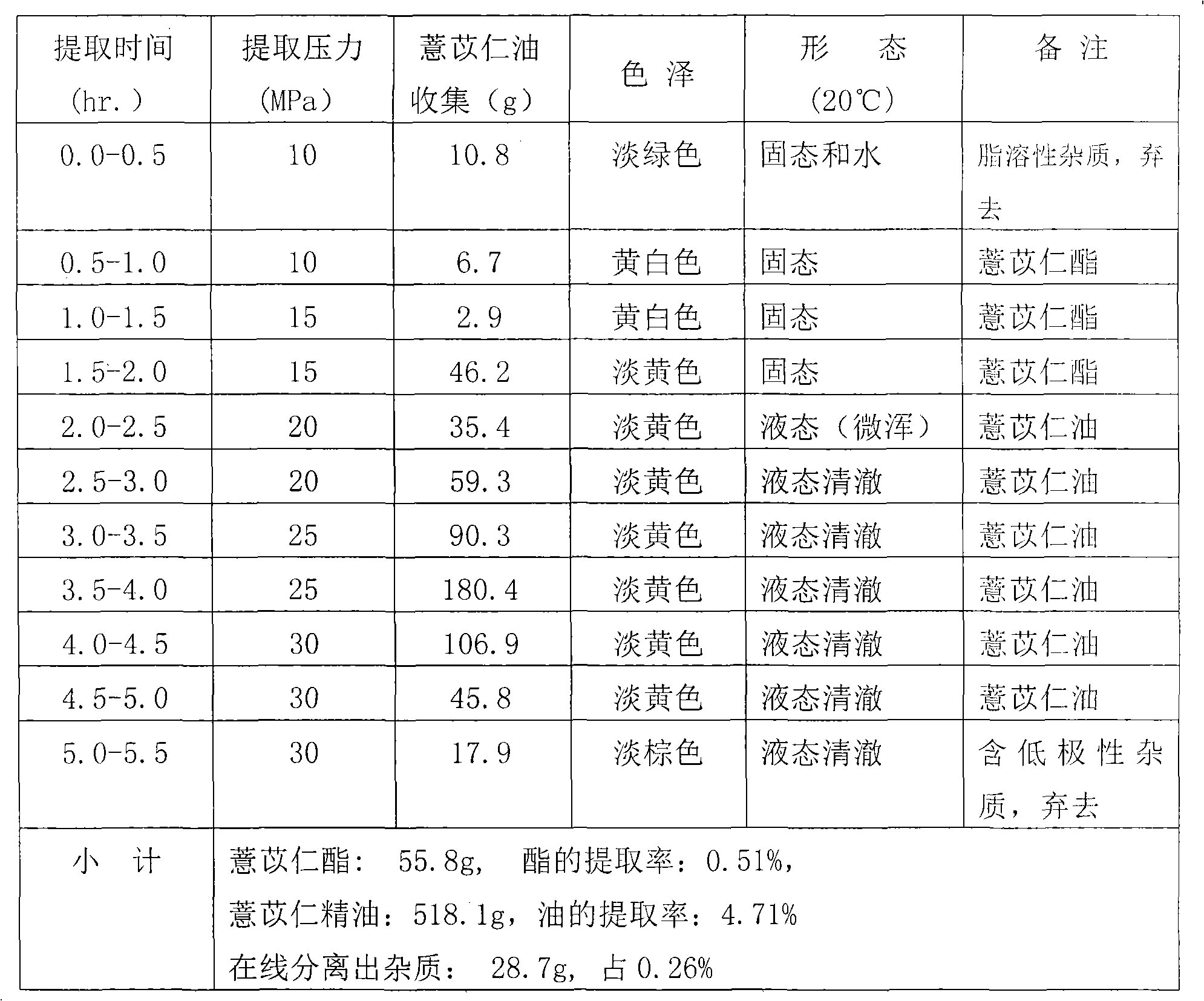

example 1

[0023]

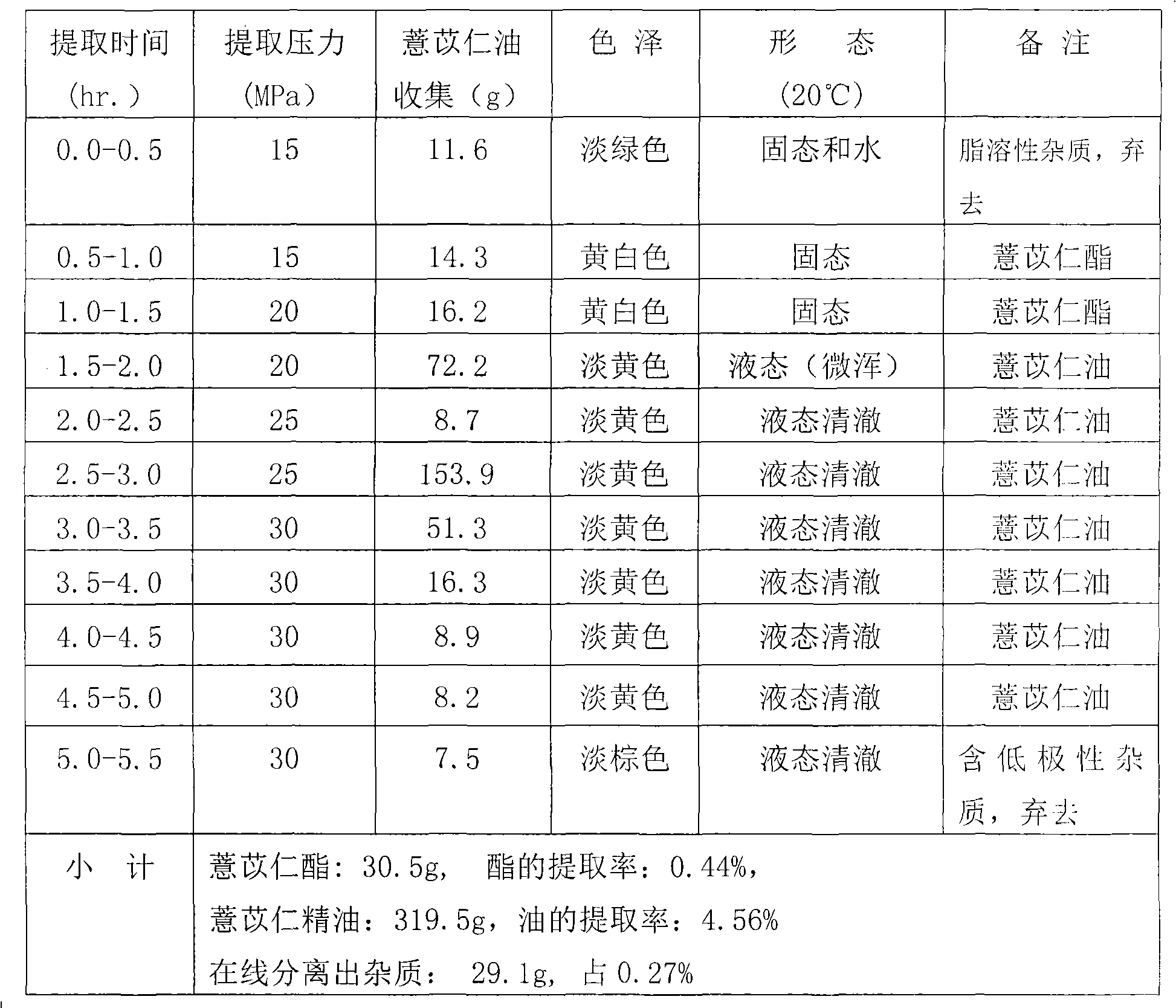

Embodiment 2

[0025]Put 7.00kg of crushed, granulated and sieved Coix seed powder, with a water content of 3.3%, into a 24L extraction kettle, the extraction temperature is 60°C, the extraction pressure is increased step by step from 15, 20, 25, 30MPa, and the pressure of the separation kettle is 6MPa Temperature 45°C, CO 2 The flow rate is 100L / hr, and the extraction time is 0.5hr / segment to collect. The specific process and results are shown in Table 2. Other unmentioned parts are the same as the above example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com