Material transfer method and transfer device

A transfer device and material technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of material spreading, cutting tape, tape deviation, etc., and achieve the effect of reducing wear, avoiding being torn, and preventing deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

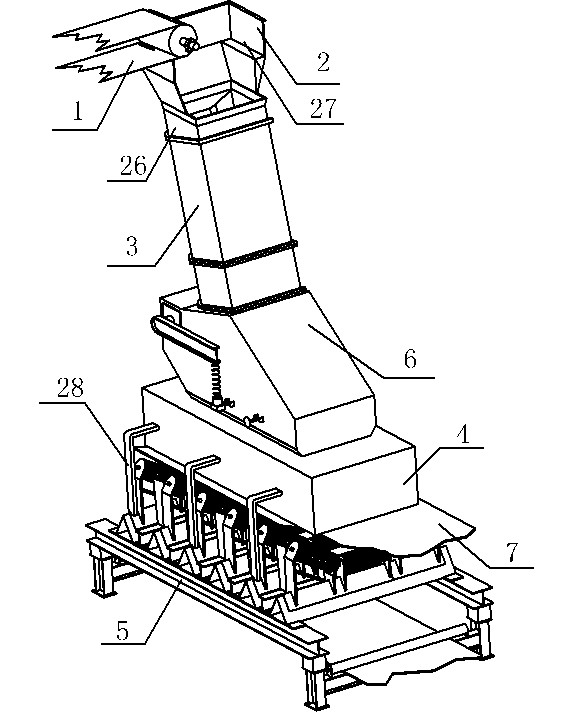

[0039] Embodiment 1 of the present invention: a material transfer device for reloading small granular materials, its structure is as follows figure 1 As shown; including feeding belt machine 1, unloading funnel 2, guide material centering chute 3, material guide trough 4, material receiving buffer device with pallet 5, material receiving belt 7; unloading funnel 2 and guide material centering chute 3 are connected, the lower part of the centering chute 3 is inserted into the guide trough 4, and the guide trough 4 is placed on the receiving buffer device 5 with a pallet, and the feed trough 4 is connected with the receiving buffer device 5 with a pallet through the connecting frame 28. The material buffer device 5 is connected, and the buffer fork 6 conveys the material to the material receiving tape 7 on the material receiving belt machine.

[0040] The front plate and both side plates of the unloading funnel 2 are provided with a stacking mechanism 8; the stacking mechanism 8...

Embodiment 2

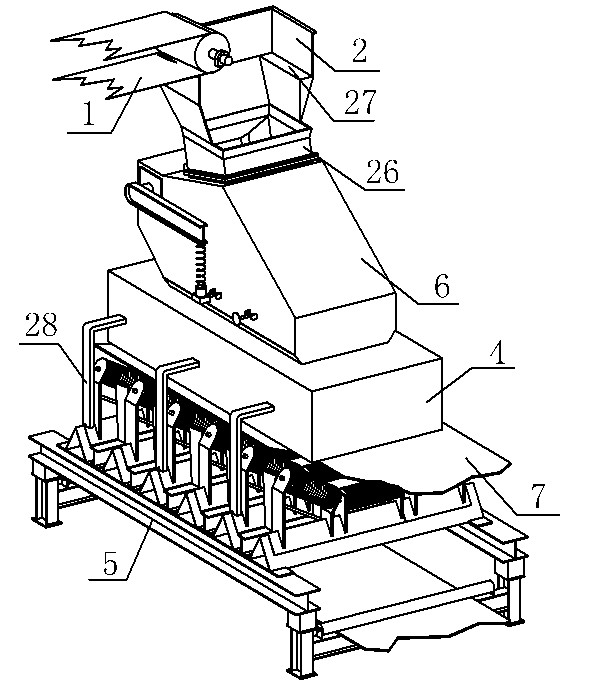

[0045] Embodiment 2 of the present invention: be used for reprinting bulk material, as: the transfer device of coal etc., comprise feeding tape conveyor 1, unloading funnel 2, guide chute 4, the material receiving buffer device 5 with supporting plate, buffer Fork 6, material receiving tape 7; unloading funnel 2 is connected with middle funnel 26, and middle funnel 26 is connected with buffer fork 6, and the bottom of buffer fork 6 is inserted in feed channel 4, and feed guide channel 4 is a closed metal box. The material guide trough 4 is placed on the material receiving buffer device 5 with a pallet, the material guide trough 4 is connected with the material receiving buffer device 5 with a pallet through the connecting frame 28, and the buffer fork 6 conveys the material to the material receiving device on the material receiving belt conveyor. Tape 7 on.

[0046] The front plate and the two side plates of the unloading funnel 2 are provided with a stacking mechanism 8;

[...

Embodiment 3

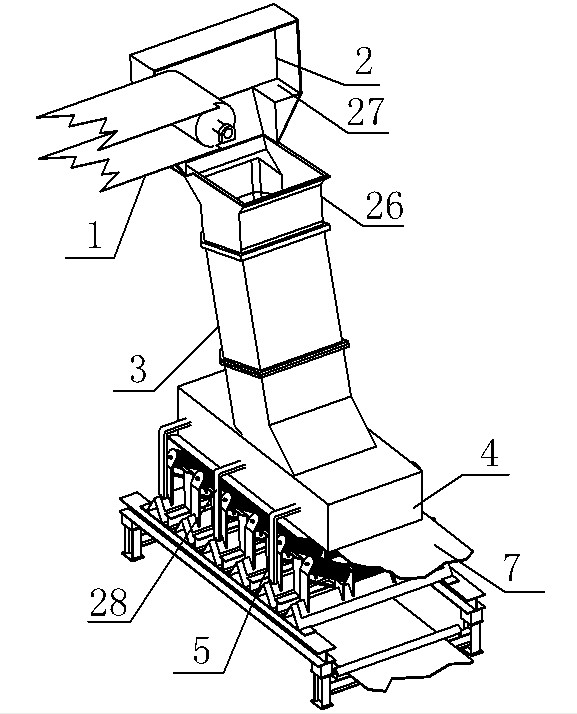

[0050] Embodiment 3 of the present invention: a material transfer device, used for reprinting small pieces of material, such as sand and stones; it includes a feeding tape machine 1, an unloading funnel 2, a material guide centering chute 3, a material guide trough 4, Material receiving buffer device 5 with pallet, buffer fork 6, material receiving tape 7; unloading funnel 2 is connected with middle funnel 26, middle funnel 26 is connected with guide centering chute 3, guide material centering chute 3 is connected with buffer fork 6 are connected, the lower part of the buffer fork 6 is inserted into the material guide trough 4, the material guide trough 4 is a closed metal box, the material guide trough 4 is placed on the receiving buffer device 5 with a pallet, the material guide trough 4 passes The connecting frame 28 is connected with the material-receiving buffer device 5 with a pallet, and the buffer fork 6 conveys the material to the material-receiving tape 7 on the mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com