Method and device for biological degumming of ramie

A technology of biological degumming and ramie, which is applied in the fields of plant raw materials, bacterial retting, textiles and paper making, etc., can solve the problems of environmental pollution, waste liquid pollution, shorten the degumming time, etc., so as to improve the degumming quality, improve the fermentation efficiency, shorten the The effect of degumming time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Re-drying the ramie from Yuanjiang, Hunan, so that the moisture content of the ramie is 10%;

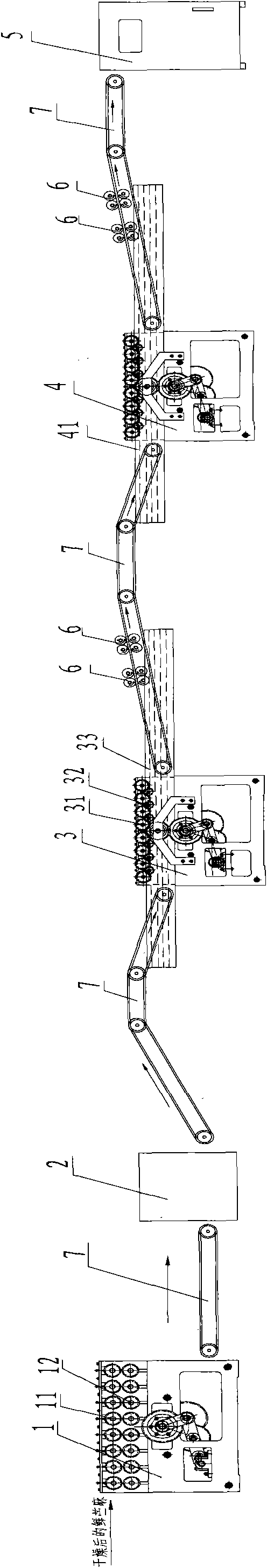

[0069] use as figure 1 The dehulling machine shown dehulls and pre-fibers the dried fresh ramie;

[0070] Put the raw hemp after peeling and pre-fibering into the hemp pot, the thickness of the hemp in the hemp pot is 60mm-120mm; move the hemp pot into the fermentation equipment disclosed in Chinese patent document 200620050490.7, and the weight of the raw hemp in the fermentation equipment is 500kg;

[0071] Erwinia carrot soft rot was expanded and then diluted with tap water to a viable count of 10 7 cfu / mL bacterial suspension, according to the bath ratio of 1:10, soak the raw hemp in the fermentation equipment when the water temperature is 37 ° C and pH is 4.5; then adjust the temperature in the fermentation equipment to 37 ± 1 ° C, so that The raw hemp in the fermentation equipment is shaken and fermented at a speed of 60r / min for 8 hours;

[0072] After the fermented ...

Embodiment 2

[0076] The ramie produced in Yuanjiang, Hunan is dried again, so that the moisture content of ramie is 12%;

[0077] use as figure 1 The dehulling machine shown dehulls and pre-fibers the dried fresh ramie;

[0078] Put the raw hemp after peeling and pre-fibering into the hemp pot, the thickness of the hemp in the hemp pot is 150mm; move the hemp pot into the fermentation equipment disclosed in Chinese patent document 200620050490.7, the weight of the raw hemp in the fermentation equipment is 600kg;

[0079] Erwinia carrot soft rot was expanded and then diluted with tap water to a viable count of 10 7 cfu / mL bacterial suspension, according to the bath ratio of 1:10, soak the raw hemp in the fermentation equipment when the water temperature is 37 ° C and pH is 4.5; then adjust the temperature in the fermentation equipment to 37 ± 1 ° C, so that The raw hemp in the fermentation equipment is shaken and fermented at a speed of 160r / min, and fermented for 10h;

[0080] Wash and ...

Embodiment 3

[0084] The ramie produced in Yuanjiang, Hunan is dried again, so that the moisture content of ramie is 11%;

[0085] use as figure 1 The dehulling machine shown dehulls and pre-fibers the dried fresh ramie;

[0086] Put the raw hemp after peeling and pre-fibering into the hemp pot, the thickness of the hemp in the hemp pot is 100mm; move the hemp pot into the fermentation equipment disclosed in Chinese patent document 200620050490.7, the weight of the raw hemp in the fermentation equipment is 400kg;

[0087] Erwinia carrot soft rot was expanded and then diluted with tap water to a viable count of 10 7cfu / mL bacterial suspension, according to the bath ratio of 1:10, soak the raw hemp in the fermentation equipment when the water temperature is 37 ° C and pH is 5.5; then adjust the temperature in the fermentation equipment to 37 ± 1 ° C, so that The raw hemp in the fermentation equipment is shaken and fermented at a speed of 130r / min, and fermented for 9h;

[0088] After the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com