Microalloying copper alloy

A microalloying and copper alloying technology, applied in the field of non-ferrous metal preparation, can solve the problems of lower yield, poor economy, multiple cracks, peeling, markings, etc., to improve the surface finish, meet the normal use requirements, and beautiful appearance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

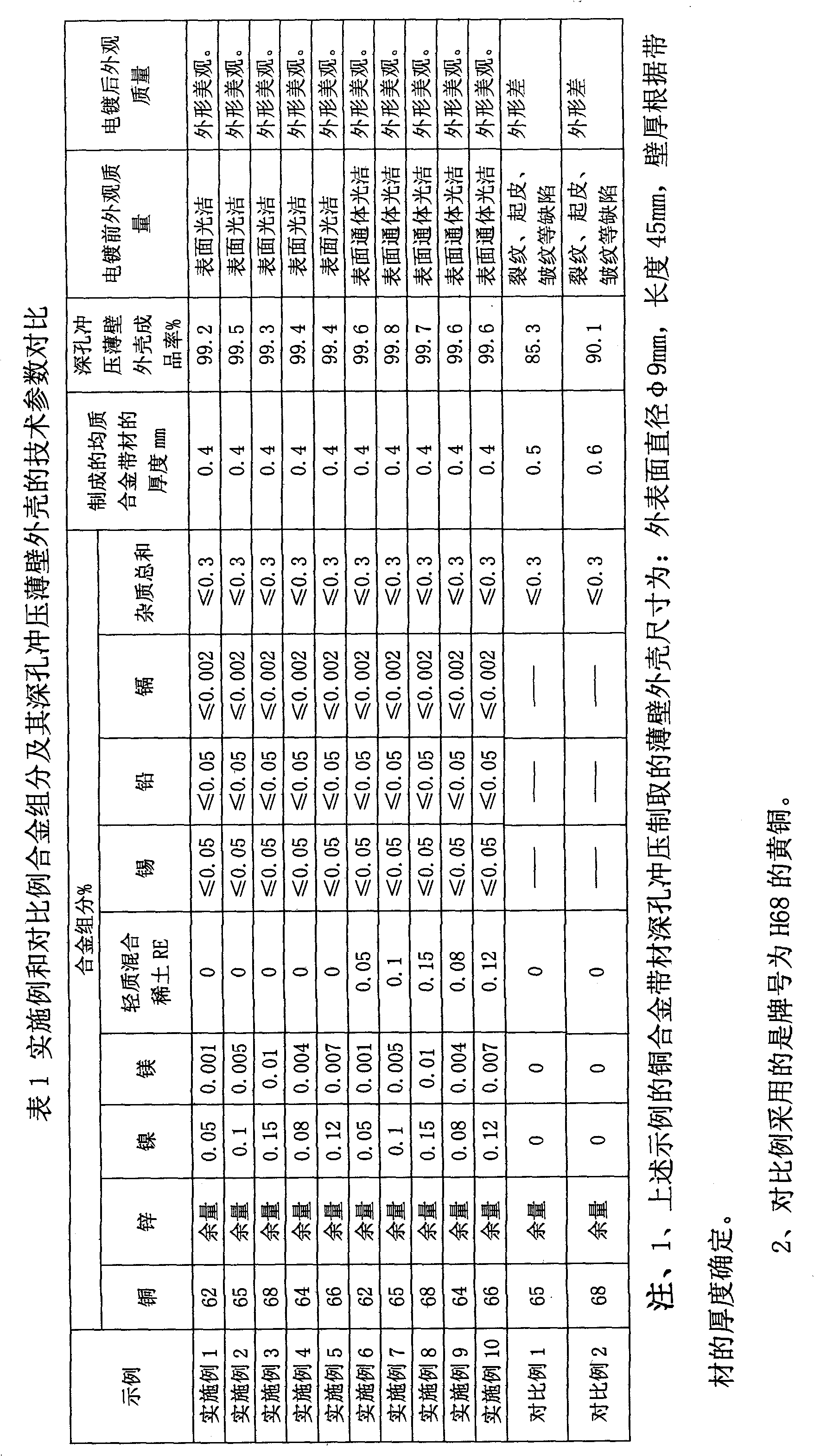

[0015] Embodiment 1: see table 1, a kind of microalloyed copper alloy, its composition by mass percentage is: copper 62%, nickel 0.05%, magnesium 0.001%, mixed rare earth Re 0%, surplus is zinc and other unavoidable Impurities, and the content of impurities in the whole alloy is ≤0.3%, the content of tin, one of the harmful elements in the impurity, is ≤0.05% in the whole alloy, the sum of other non-essential impurities is ≤0.25%, and one of the non-essential impurities The mass percentage content of the element lead is ≤0.05%, and the mass percentage content of the cadmium is ≤0.002%.

[0016] The copper alloy made according to the above ratio, the thickness of the homogeneous copper alloy strip made of the copper alloy is 0.4mm, the yield of the thin-walled shell formed by deep hole punching is 99.2%, the surface of the thin-walled shell is smooth, there is no obvious Defects such as cracks, peeling, wrinkles, etc., after the surface is electroplated with nickel, the color a...

Embodiment 2

[0017] Embodiment 2: see table 1, a kind of microalloyed copper alloy, its composition by mass percentage is: copper 65%, nickel 0.1%, magnesium 0.005%, mixed rare earth Re 0%, surplus is zinc and other unavoidable Impurities, and the content of impurities in the whole alloy is ≤0.3%, the content of tin, one of the harmful elements in the impurity, is ≤0.05% in the whole alloy, the sum of other non-essential impurities is ≤0.25%, and one of the non-essential impurities The mass percentage content of the element lead is ≤0.05%, and the mass percentage content of the cadmium is ≤0.002%.

[0018] The copper alloy made according to the above ratio, the thickness of the homogeneous copper alloy strip made of the copper alloy is 0.4mm, the yield of the thin-walled shell formed by deep hole punching is 99.5%, the surface of the thin-walled shell is smooth, there is no obvious Defects such as cracks, peeling, wrinkles, etc., after the surface is electroplated with nickel, the color an...

Embodiment 3

[0019] Embodiment 3: see table 1, a kind of microalloyed copper alloy, its composition by mass percentage is: copper 68%, nickel 0.15%, magnesium 0.01%, mixed rare earth Re 0%, surplus is zinc and other unavoidable Impurities, and the content of impurities in the whole alloy is ≤0.3%, the content of tin, one of the harmful elements in the impurity, is ≤0.05% in the whole alloy, the sum of other non-essential impurities is ≤0.25%, and one of the non-essential impurities The mass percentage content of the element lead is ≤0.05%, and the mass percentage content of the cadmium is ≤0.002%.

[0020] The copper alloy made according to the above ratio, the thickness of the homogeneous copper alloy strip made of the copper alloy is 0.4mm, the yield of the thin-walled shell formed by deep hole punching is 99.3%, the surface of the thin-walled shell is smooth, there is no obvious Defects such as cracks, peeling, wrinkles, etc., after the surface is electroplated with nickel, the color an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com