Catalyst used for hydrogenation of oxalate for preparing ethylene glycol and preparation method thereof

A catalyst and ethylene glycol technology, applied in chemical instruments and methods, preparation of hydroxyl compounds, organic compounds, etc., can solve pollution hazards and other problems, achieve environmental friendliness, enhance anti-sintering ability, high activity and ethylene glycol selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

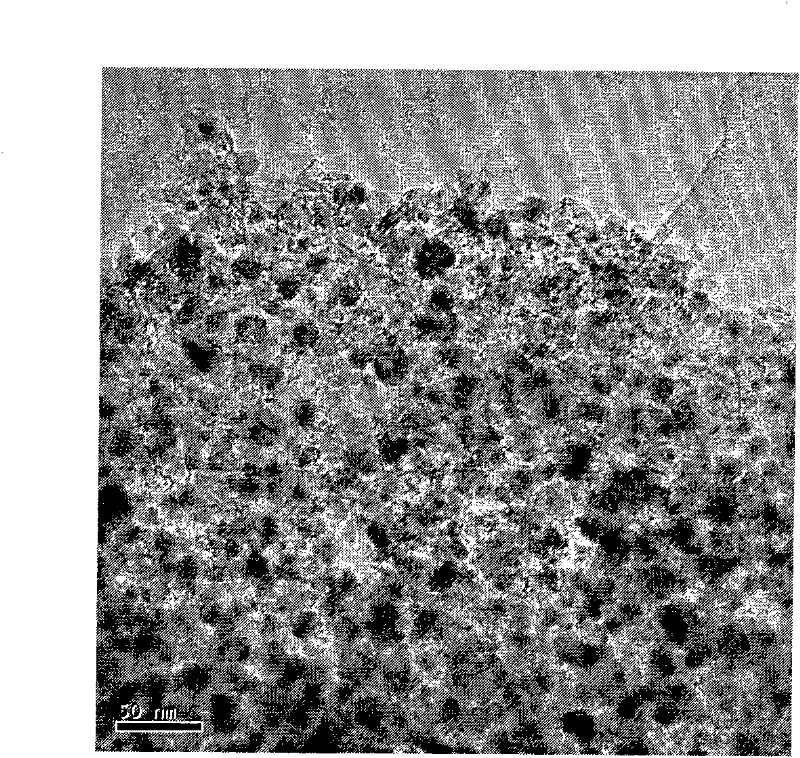

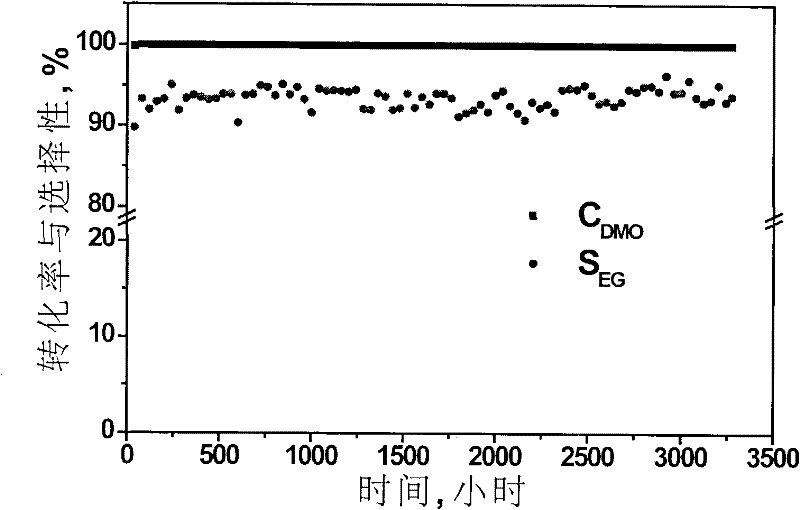

Method used

Image

Examples

Embodiment 1

[0031] Preparation of Zirconium Glue

[0032] Weighing 30g Zr(NO 3 ) 4 ·5H 2 O was added to a 200ml beaker, and 100ml of 70% nitric acid was added to dissolve it and adjust the Zr(NO 3 ) 4 The concentration is 2M. Under the stirring state, ammonia water was slowly added dropwise in the solution until the pH was 4.0-5.0, at this time Zr(NO 3 ) 4 The solution is transformed into a translucent zirconium sol, and deionized water is added to adjust the concentration of the zirconium sol to 1 mol / L, and then aged under air atmosphere for 24-48 hours with stirring.

[0033] Catalyst preparation

[0034] Weigh 15.25g of copper nitrate pentahydrate and dissolve it in 120ml of water, slowly add 52ml of 25% ammonia water to dissolve it and mix well. The zirconium colloid and silica sol (silicon oxide content is 30wt. %) prepared before are added dropwise in this solution, and the volumes of zirconium colloid and silica sol are respectively 113ml and 6ml. The temperature is then ...

Embodiment 2

[0048] Preparation of Zirconium Glue

[0049] Zirconium glue preparation method is the same as embodiment 1

[0050] Catalyst preparation

[0051] Weigh 15.25g of copper nitrate pentahydrate and dissolve it in 100ml of water, slowly add 52ml of 25% ammonia water to dissolve it and mix well. 113ml of the previously prepared zirconium glue was added dropwise to the solution, and after the dropwise addition was completed, it was aged for 2 hours under stirring. A total of 6ml of silica sol was added dropwise to the above-mentioned material, and after the dropwise addition was completed, it was aged for 2 hours under stirring. Then the temperature is raised to 95°C to precipitate copper, zirconia and silicon oxide. The precipitate was filtered, washed three times with deionized water, dried at 120°C for 12 hours, and calcined at 450°C for 4 hours to form a copper content of 20wt.%, SiO 2 10wt.% Cu / ZrO 2 / SiO 2 Catalyst ready for use.

[0052] Catalyst evaluation

[0053] T...

Embodiment 3

[0055] Preparation of Zirconium Glue

[0056] Weighing 12.0g Zr(OH) 4 Add it into a 200ml beaker and add water to make a suspension, slowly add nitric acid dropwise under stirring to dissolve it, add ammonia water dropwise until the pH is 4.0-5.0, at this time a translucent zirconium sol is formed, add deionized water to adjust the zirconium The concentration of the sol is 1 mol / L, and then it is stirred and aged in an air atmosphere for 24-48 hours before use.

[0057] Catalyst preparation

[0058] Other is the same as embodiment 1, but adopts the zirconium sol prepared in the present embodiment to replace with Zr(NO 3 ) 4 ·5H 2 O is the zirconium sol prepared by raw material to obtain copper content of 20wt.%, SiO 2 10wt.% Cu / SiO 2 / ZrO 2 Catalyst ready for use.

[0059] Catalyst evaluation

[0060] The catalyst evaluation method is the same as in Example 1, and the results are shown in Table 1.

[0061] Table 1 Cu / SiO prepared using different methods and precursor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com