Combined PNP-trench isolation RC-GCT component and preparation method thereof

A technology of RC-GCT and devices, which is applied in the manufacture of semiconductor/solid-state devices, semiconductor devices, electrical components, etc., can solve the problems of difficult manufacturing process and high cost, reduce the difficulty and cost of manufacturing process, and save the control of the minority lifetime required effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

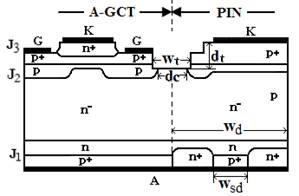

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

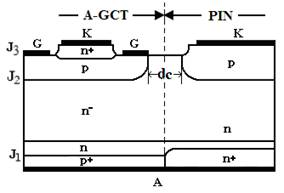

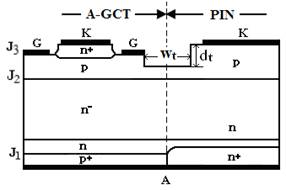

[0033] Fig. 1 is a comparison of the basic structure sections of the RC-GCT device of the present invention and the existing pnp isolation RC-GCT and trench isolation RC-GCT.

[0034] Figure 1a It is the structure diagram of the existing RC-GCT device. The pnp isolation method is adopted between the A-GCT and the PIN diode. No matter whether the voltage between G and K is positive or negative, there is always a pn junction in the pnp that is reverse-biased. Therefore, the pnp The essence of isolation is pn junction isolation, the leakage current is very small, and the isolation effect is very good. However, the pnp structure requires silicon nitride (Si 3 N 4 ) under the cover of the masking film is realized by the selective deep diffusion of p-type impurity aluminum, which makes the manufacturing process very difficult and the cost is al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com