Technology for preparing biodiesel by food and beverage waste oil

A biodiesel and catering waste oil technology, which is applied in biofuel, fat oil/fat refining, petroleum industry, etc., can solve the problems of reaction influence, slow reaction rate, and large amount of acid-catalyzed methanol, so as to avoid pollution, low cost, The effect of solving the problems of secondary pollution and corrosion equipment

Inactive Publication Date: 2010-10-06

LOGISTICAL ENGINEERING UNIVERSITY OF PLA

View PDF3 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The amount of methanol used in acid catalysis is large, the reaction rate is slow, and acidic waste water is produced. The conditions of alkali catalyzed transesterification reaction are mild. Although a high conversion rate can be obtained in a short reaction time, the content of free fatty acids and water in the raw material oil has an impact on the reaction. Obvious impact, produce alkaline wastewater

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

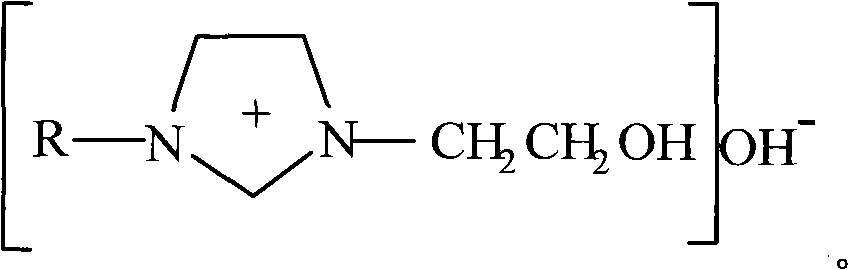

The embodiment of the invention discloses a method for manufacturing biodiesel, which is characterized in that the method comprises the following steps: filtering food and beverage waste oil by an oil filter; then, heating the waste oil for dewatering; carrying out esterification reaction on the pretreated food and beverage waste oil and methanol or ethanol in the existence of catalysts of basic ionic liquid; carrying out distillation for recovering the rest methanol in the reaction; separating the basic ionic liquid catalysts and the glycerin phase in the reaction lower layer liquid to obtain coarse ester; washing obtained materials by hot water to neutral materials after the coarse ester is washed by saturated sodium chloride solution water; and finally, carrying out heating, stirring and dewatering to obtain finished products of biodiesel. The basic ionic liquid catalysts have the molecular formula as the accompanying drawing.

Description

technical field The invention relates to the field of biodiesel production, more specifically, relates to the technology of producing biodiesel from waste cooking oil. Background technique At present, the tense situation in the oil market has put forward a realistic demand for the development of biodiesel. From the perspective of the development of biodiesel at home and abroad, due to the increase in the price of agricultural products worldwide in the past two years, the cost of biodiesel using vegetable oil as raw material has increased. From an economic point of view, it is not feasible to completely replace petroleum diesel with biodiesel in the short term, but it is feasible to use leftovers such as waste cooking oil and acidified oil as raw materials. Converting catering waste oil into biodiesel not only avoids the problem of competing with the public for producing biodiesel directly from vegetable oil, but also eliminates the pollution of this kind of waste to the ecol...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C11C3/10C11B3/00C10L1/02

CPCY02E50/13Y02E50/10

Inventor 陈立功

Owner LOGISTICAL ENGINEERING UNIVERSITY OF PLA

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com