Method for extracting tea seed oil from tea tree seeds

A technology of tea seed oil and tea tree, which is applied in the direction of fat oil/fat production and fat generation, can solve the problems of poor product quality, residue, product odor, etc., achieve high nutritional value and medicinal value, protect natural nutritional components, Reduce the effect of cardiovascular sclerosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

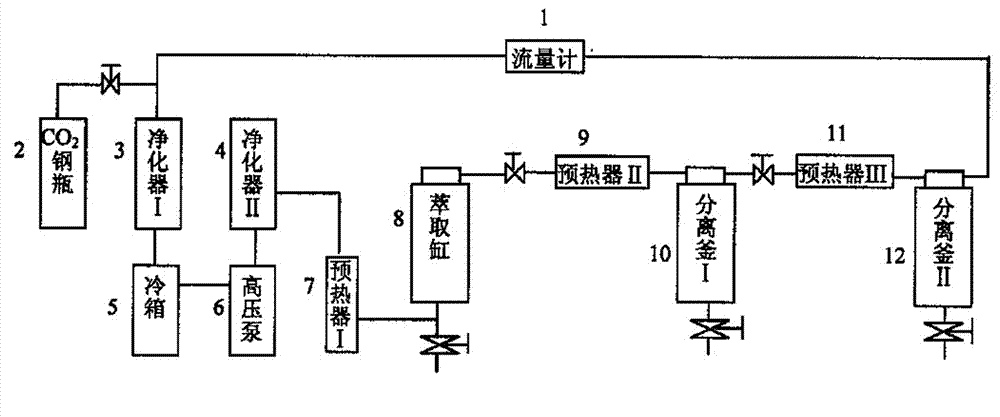

[0012] refer to figure 1 : (1) Dry 2Kg tea tree seeds, crush them to 20 mesh and put them into the barrel of 5L extraction tank 8; (2) Set the temperature of cold box 5 to 0°C, and set the temperature of extraction tank 8 to 35 ℃, the temperature of the separation tank I10 is set to 55 °C, the temperature of the separation tank II12 is set to 55 °C, and the CO 2 Cylinder 2, CO 2 Come out of the steel cylinder 2, enter the cold box 5 for liquefaction through the gas purifier I3, and then start the high-pressure pump 6 to remove the CO 2 After purifier Ⅱ4 and preheater Ⅰ7, it enters the extraction cylinder 8, boosts the pressure to 30MPa, makes it a supercritical fluid for extraction, and enters the preheater Ⅱ9 to preheat before entering the separation system. The complete separation of similar substances can reduce the follow-up processing work, adopt secondary separation, adjust the pressure of the separation tank I10 to 10MPa, and keep the pressure of the separation tank I...

Embodiment 2

[0015] Dry 2Kg tea tree seeds, crush them to 30 mesh, control the pressure of the extraction tank to 35MPa, set the temperature to 40°C, adjust the pressure of the separation kettle I to 9MPa, set the temperature to 55°C, and set the temperature of the separation kettle II to 55 ℃, other with embodiment 1, extract 3 hours, collect grease 308g, extraction rate is 15.4%.

[0016] The content of unsaturated fatty acid in the sample was determined by GC-MS method to be 82.7%; the content of tea polyphenols in the sample was determined by iron tartrate chromogenic method to be 8.3%; the content of vitamin E in the sample was determined to be 1.34 mg / g by UV spectrophotometry.

Embodiment 3

[0018] Dry 2Kg of tea tree seeds, crush them to 40 meshes, control the pressure of the extraction cylinder to 25MPa, set the temperature to 55°C, adjust the pressure of the separation kettle I to 8MPa, set the temperature to 60°C, and set the temperature of the separation kettle II to 60°C ℃, other is the same as embodiment 1, extracts 2.5 hours, collects fat 254g, and extraction rate is 12.7%. The content of unsaturated fatty acid in the sample was determined by GC-MS method to be 83.4%; the content of tea polyphenols in the sample was determined by iron tartrate chromogenic method to be 7.9%; the content of vitamin E in the sample was determined to be 1.49 mg / g by UV spectrophotometry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com