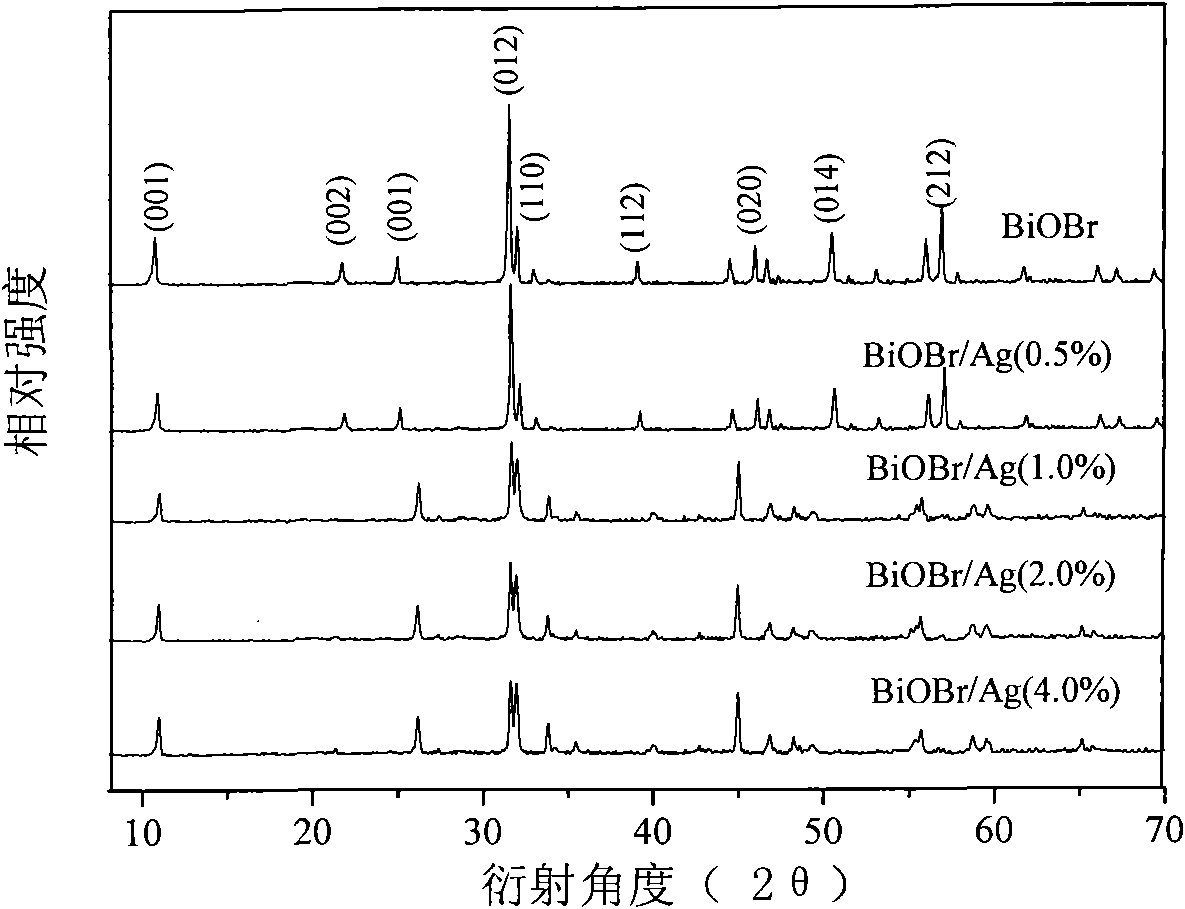

Ag doped BiOBr catalytic material and preparation method and application thereof

A catalytic material and composite photocatalytic technology, applied in Ag-doped BiOBr catalytic material and its preparation and application field, can solve the problems of limited visible light response, unstable doping system, limited red shift degree, etc., and achieve strong visible light response performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

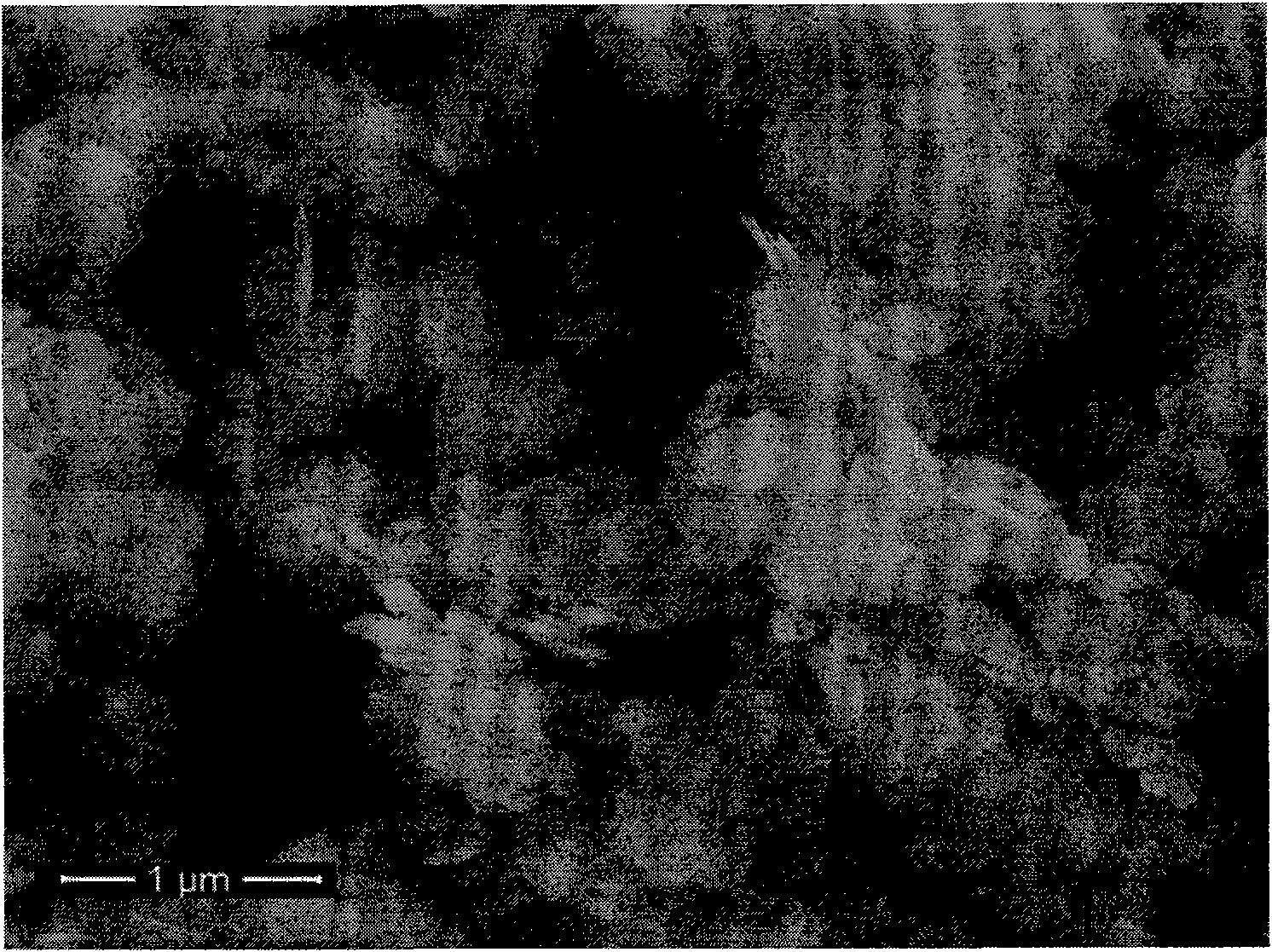

Embodiment 1

[0038] Add 0.01 mole Bi(NO 3 ) 3 ·5H 2 O, stirring to obtain solution A, adding 0.01 mole of NaBr and 0.02 mole of sodium acetate in 7 milliliters of deionized water to obtain solution B. Under vigorous stirring, solution A and solution B were rapidly mixed, stirred with a magnetic stirrer for 12 hours, filtered, washed with deionized water, and dried at 100° C. for 12 hours to obtain the BiOBr compound. Disperse 1 gram of BiOBr compound in 40 milliliters of deionized water, add 7.9 milligrams of silver nitrate and 4 milliliters of methanol at the same time, pass high-purity helium with a flow rate of 5 milliliters / min into the suspension, and while stirring, irradiate with 365 nm ultraviolet light for 4 hours, filtered, and the solid product obtained by filtering was rinsed three times with distilled water and ethanol respectively, and then dried at 100°C for 12 hours to obtain the corresponding Ag(0.5%) / BiOBr composite photocatalytic material, its characteristics and degra...

Embodiment 2

[0040] Add 0.01 mole Bi(NO 3 ) 3 ·5H 2 O, stirring to obtain solution A, adding 0.01 mole of NaBr and 0.02 mole of sodium acetate in 7 milliliters of deionized water to obtain solution B. Under vigorous stirring, solution A and solution B were rapidly mixed, stirred with a magnetic stirrer for 12 hours, filtered, washed with deionized water, and dried at 90° C. for 12 hours to obtain the BiOBr compound. Disperse 1 gram of BiOBr compound in 40 milliliters of deionized water, add 16 milligrams of silver nitrate and 4 milliliters of methanol at the same time, pass high-purity helium into the suspension at a flow rate of 10 milliliters per minute, and irradiate it with 365 nm ultraviolet light for 4 hours while stirring , filtered, and the filtered solid product was rinsed with distilled water and ethanol three times respectively, and then dried at 100°C for 12 hours to obtain the corresponding Ag(1%) / BiOBr composite photocatalytic material, its characteristics and degradation r...

Embodiment 3

[0042] Add 0.01 M BiNO to 7 mL of glacial acetic acid 3 ·5H 2 O, stirring to obtain solution A, adding 0.01 mole of NaBr and 0.02 mole of sodium acetate in 7 milliliters of deionized water to obtain solution B. Under vigorous stirring, solution A and solution B were rapidly mixed, stirred with a magnetic stirrer for 12 hours, filtered, washed with deionized water, and dried at 110°C to obtain the BiOBr compound. Disperse 1 gram of BiOBr compound in 40 milliliters of deionized water, add 32.5 milligrams of silver nitrate and 4 milliliters of methanol at the same time, pass high-purity helium into the suspension at a flow rate of 15 milliliters per minute, and irradiate it with 365 nm ultraviolet rays for 4 hours while stirring , filtered, and the filtered solid product was rinsed three times with distilled water and ethanol respectively, and then dried at 100°C for 12 hours to obtain the corresponding Ag(2%) / BiOBr composite photocatalytic material, its characteristics and degr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com