Self-setting calcium phosphate micro spheres, method for preparing same and application thereof

A calcium phosphate microsphere, self-curing technology, used in dental preparations, pharmaceutical formulations, medical science and other directions, can solve the problem of inability to combine the anti-disintegration and degradability of microspheres at the same time, and achieve good bone defect repair and performance. Therapeutic effect, good biodegradability and non-toxic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

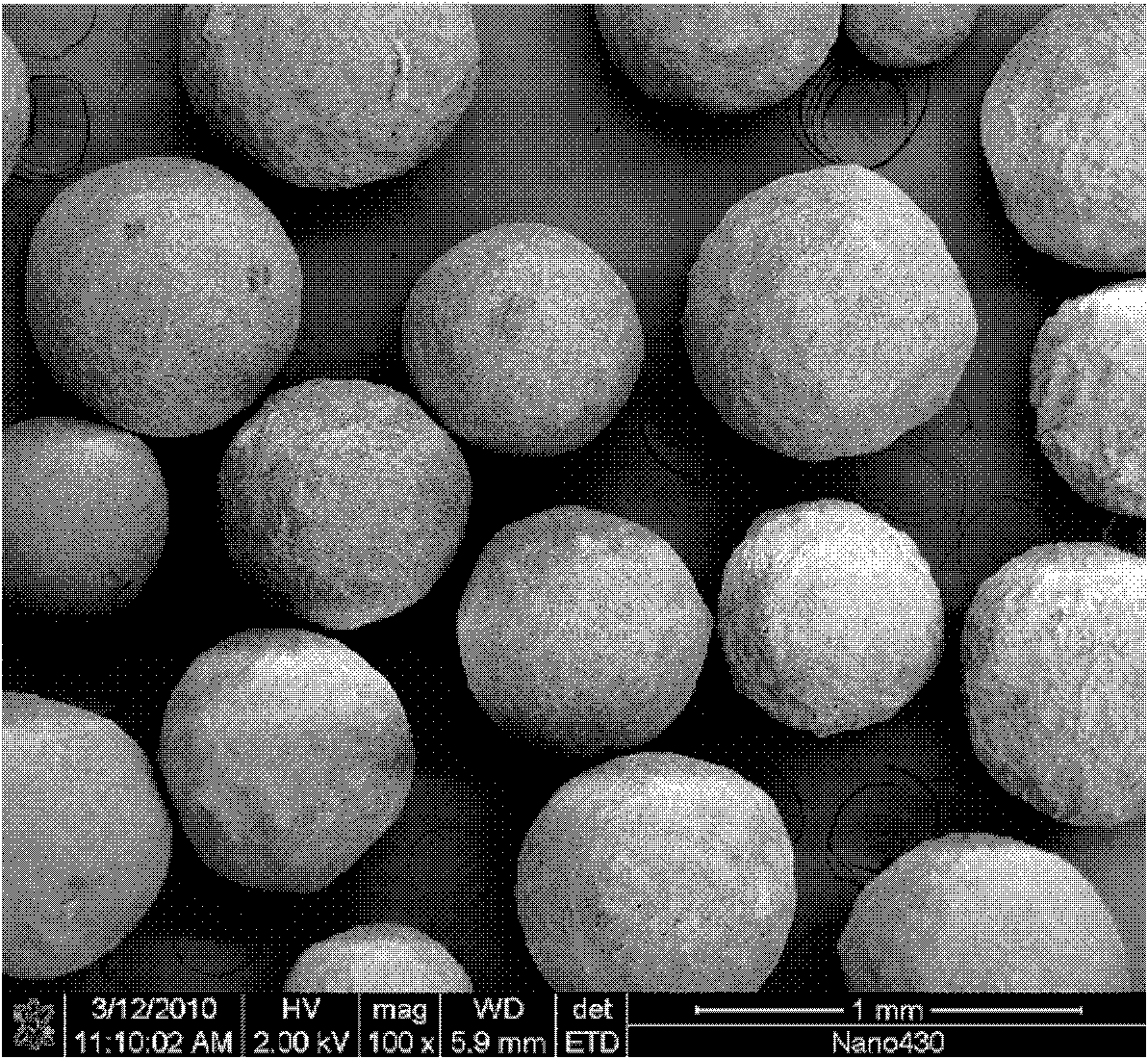

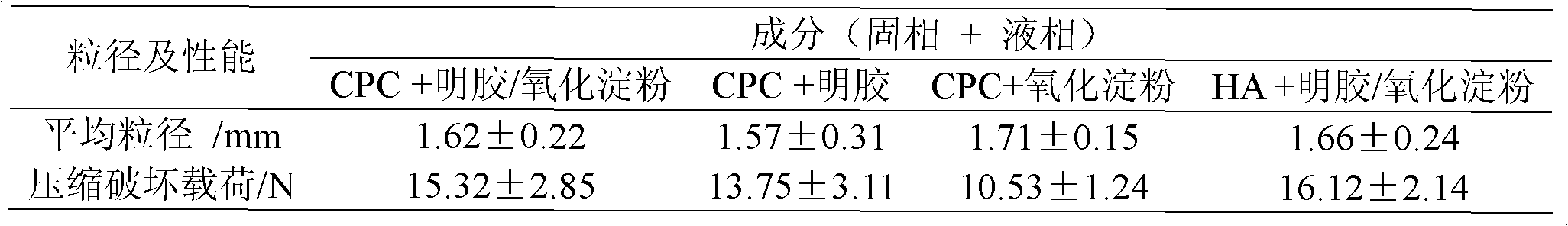

Image

Examples

Embodiment 1

[0037] The steps of preparing self-curing calcium phosphate microspheres using gelatin and oxidized starch as binder include:

[0038] (1) Add gelatin particles (Sinopharm Chemical Reagent Co., Ltd., F20071019, chemically pure) to 42°C deionized water at a ratio of 4g / 100mL to fully swell, and stir with a stirrer. After the gelatin particles are completely dissolved, Obtain a 4% (w / v) gelatin solution;

[0039] (2) Add oxidized starch granules (Shanghai Huipu Industrial Chemicals Co., Ltd., chemically pure) to 39°C deionized water at a ratio of 0.2g / 100mL to fully swell, and stir with a stirrer until the oxidized starch granules are completely After dissolving, a 0.2% (w / v) oxidized starch solution is obtained;

[0040] (3) The gelatin solution obtained in step (1) and the oxidized starch solution obtained in step (2) are mixed in equal volumes to obtain gelatin / oxidized starch solution as calcium phosphate bone cement blend (wherein the concentrations of gelatin and oxidized...

Embodiment 2

[0051] The steps of preparing self-curing calcium phosphate microspheres using gelatin and carboxymethyl starch as a binder include:

[0052] (1) Add gelatin particles (Sinopharm Chemical Reagent Co., Ltd., F20071019, chemically pure) to 39°C deionized water at a ratio of 6g / 100mL to fully swell, and stir with a stirrer. After the gelatin particles are completely dissolved, Obtain a 6% (w / v) gelatin solution;

[0053] (2) Add carboxymethyl starch granules (Guangzhou Jinzhujiang Chemical Co., Ltd., chemically pure) to 40°C deionized water at a ratio of 0.6g / 100mL to fully swell, and stir with a stirrer until carboxymethyl After the starch granules were completely dissolved, a 0.6% (w / v) carboxymethyl starch solution was obtained;

[0054] (3) The gelatin solution obtained in step (1) and the carboxymethyl starch solution obtained in step (2) are mixed in equal volumes to obtain gelatin / carboxymethyl starch solution as calcium phosphate bone cement blend (wherein gelatin and ca...

Embodiment 3

[0065] The steps for preparing self-curing calcium phosphate microspheres using gelatin and hydroxypropyl starch as a binder include:

[0066] (1) Add gelatin particles (Sinopharm Chemical Reagent Co., Ltd., F20071019, chemically pure) to 60°C deionized water at a ratio of 8g / 100mL to fully swell, and stir with a stirrer. After the gelatin particles are completely dissolved, Obtain 8% (w / v) gelatin solution;

[0067] (2) Add hydroxypropyl starch granules (Shanghai Huipu Industrial Chemicals Co., Ltd., chemically pure) to 40°C deionized water at a ratio of 1.2g / 100mL to fully swell, and stir with a stirrer until the hydroxypropyl starch After the starch granules were completely dissolved, a 1.2% (w / v) hydroxypropyl starch solution was obtained;

[0068] (3) The gelatin solution obtained in step (1) and the hydroxypropyl starch solution obtained in step (2) are mixed in equal volumes to obtain a gelatin / hydroxypropyl starch solution as a calcium phosphate bone cement blend (whe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com