Silage preparation process

A preparation process and technology of silage, which are applied in the preservation methods and applications of animal feed and raw materials of animal feed, can solve the problems of unbalanced supply of green fodder and low sugar content, and achieve rich crude protein content and high sugar content. , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

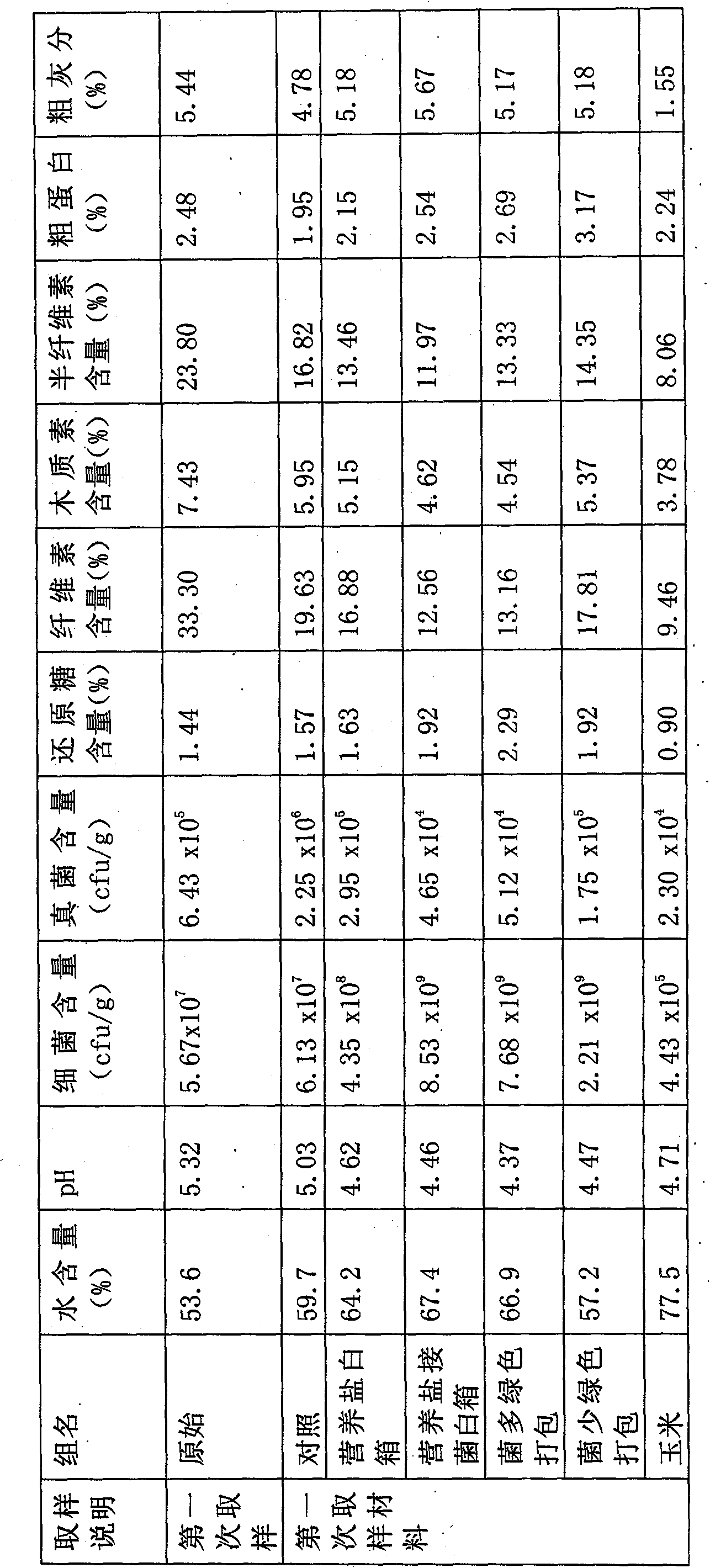

Examples

Embodiment Construction

[0023] Now, the present invention will be described in further detail in conjunction with preferred embodiments.

[0024] A kind of silage preparation technology, comprises the following steps,

[0025] S1: Collection of plant orange stalks. Freshly harvested orange stalks are selected as raw materials. During the collection process, special attention should be paid to the "six follow-ups and three essentials", namely cutting, transporting, cutting, loading, stepping on, With the seal; the raw materials should be cut short, the filling should be firmly stepped, and the top of the cellar should be sealed tightly, which is carried out continuously and completed at one time. Feed silage is a surprise job, and the silo, silage chopper or hay cutter and transport vehicles should be overhauled in advance, and enough manpower should be organized to complete it in the shortest possible time;

[0026] S2: crush the collected plant orange stalks with a pulverizer, and cut them into 2-4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com