Production method of polaroid for STN (Supper Twisted Nematic) LCD

A liquid crystal display and production method technology, applied in the directions of optics, instruments, polarizing elements, etc., can solve the problems of low composite precision and large angle deviation of polarizing film and retardation film, and achieve reduction of angle deviation, improvement of composite precision, and improvement of production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

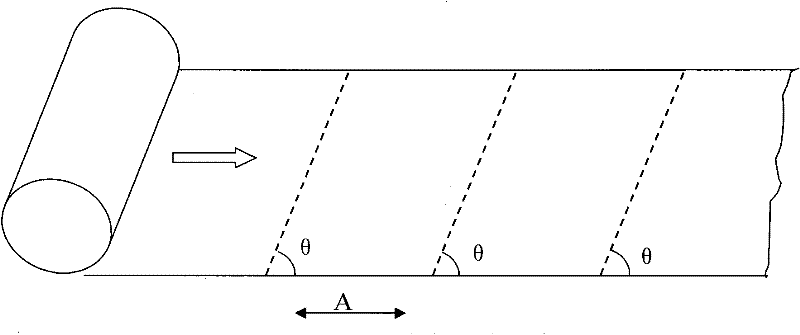

[0015] Definitions of terms and symbols in the specification of the present invention are described below.

[0016] (1) The symbol "nx" refers to the refractive index in the direction that provides the maximum in-plane refractive index (ie, the direction of the slow axis), and the symbol "ny" refers to the direction perpendicular to the slow axis (ie, the fast axis) in the same plane. direction) in the refractive index. The symbol "nz" refers to the refractive index in the thickness direction. Moreover, for example, the expression "nx=ny" not only refers to the case where nx and ny are completely equal, but also includes the case where nx and ny are substantially equal. In the description of the present invention, the phrase "substantially equal" includes the case where nx and ny are not equal in a range that does not affect the overall polarization performance of a polarizer equipped with a retardation film in practical applications.

[0017] (2) The term "in-plane retardat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com