Electrolyte for use in evaluating rinsing performance of alkaline degreaser and using method thereof

A degreaser and electrolyte technology, applied in the direction of material electrochemical variables, etc., can solve the problem of inability to characterize the rinsing performance of the degreaser, and achieve the effects of short measurement time, accurate and reliable results, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

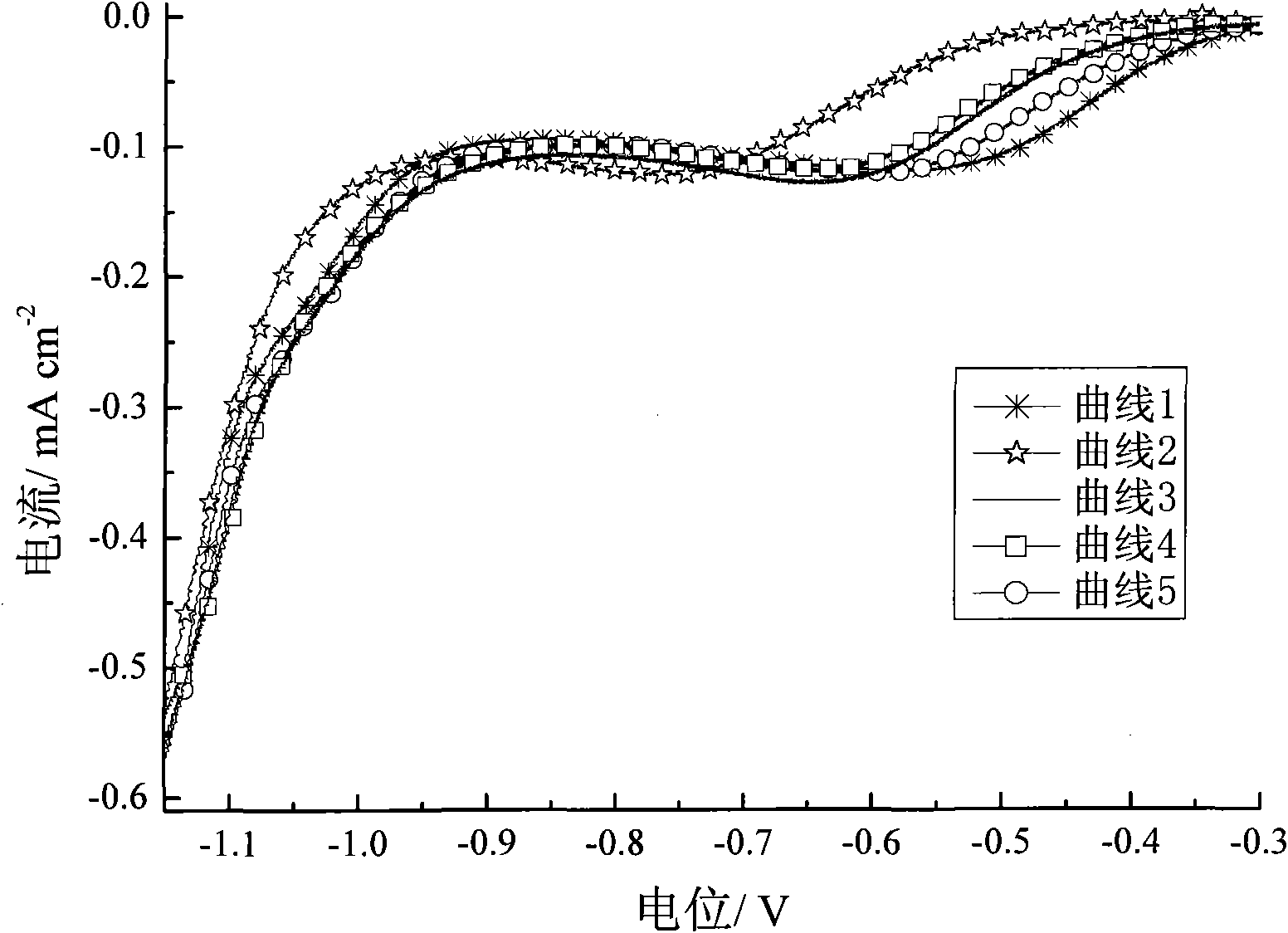

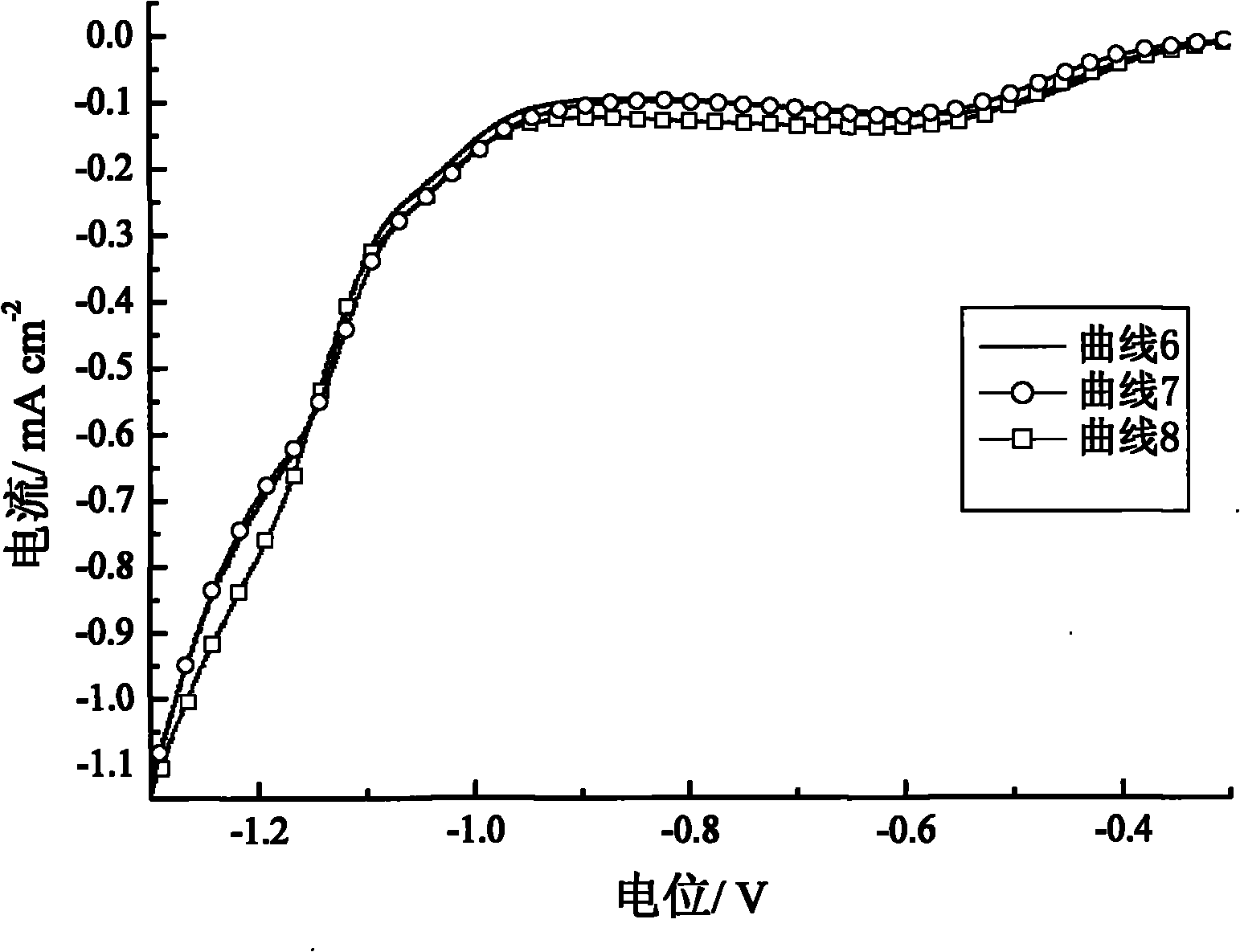

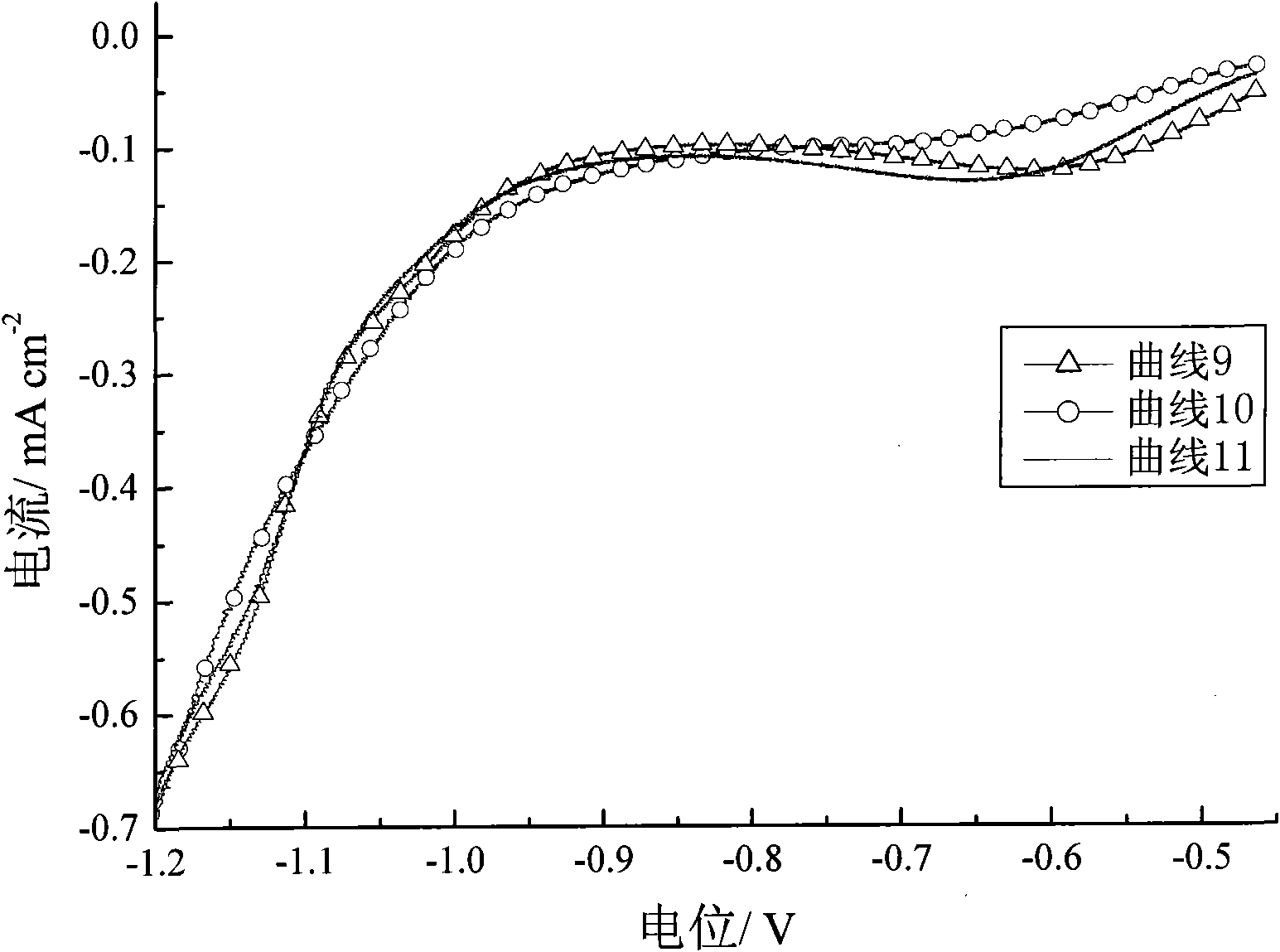

Image

Examples

Embodiment 1-6

[0048] The electrolytic solution used in the test of this embodiment, its chemical composition weight percentage ratio is shown in Table 1:

[0049] Table 1

[0050] Example

[0051] The test parameters of this embodiment are shown in Table 2

[0052] Table 2

[0053] Example

[0054] A cold-rolled steel plate that has undergone a rolling process is cut into a size of 50mm×30mm, the surface is degreased, washed with water, and then dried. The test electrolyte and test parameters are shown in Table 1 and Table 2, respectively. Soak the sample in degreasing agent, and then wash in deionized water respectively;

Embodiment 1

[0055] Example 1: Wash in deionized water for 6 seconds.

Embodiment 2

[0056] Example 2: Wash in deionized water for 9 seconds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com