New process for micro electric field reinforced low-carbon nitrogen removal

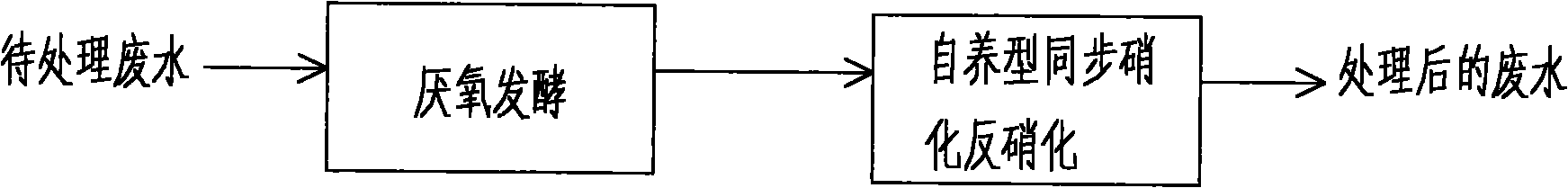

A micro-electric field and new process technology, applied in aerobic and anaerobic process treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. Widespread application and other problems, to achieve the effect of solving low efficiency, avoiding emissions, and small CO2 emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

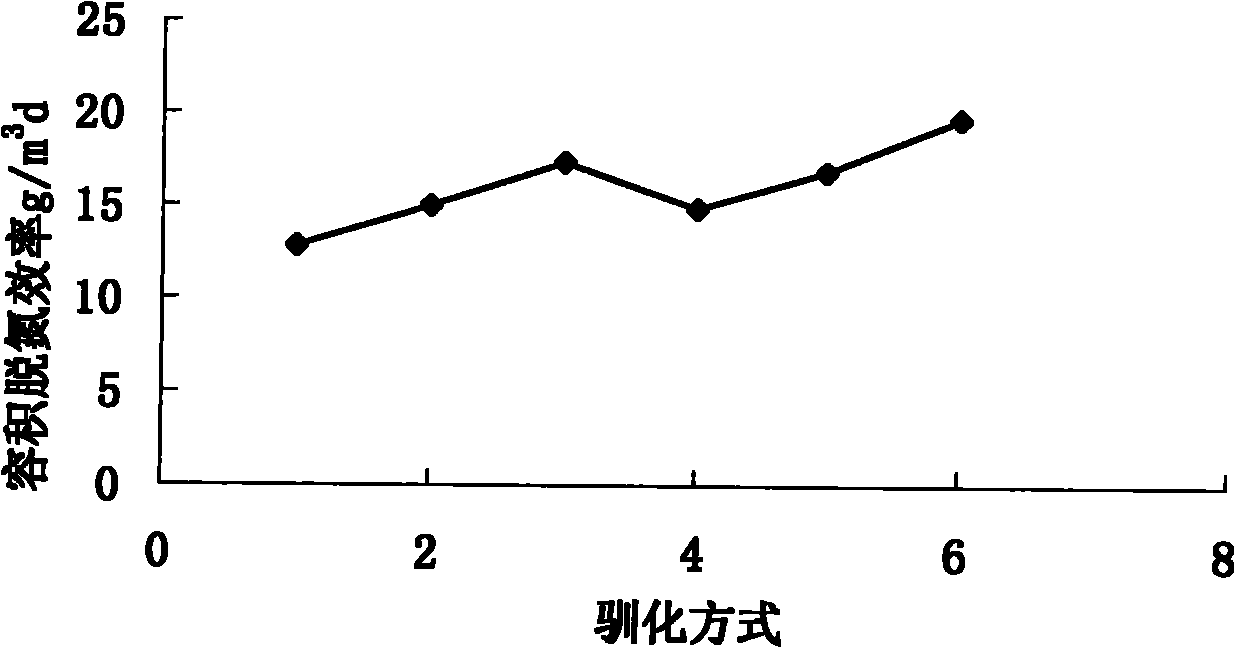

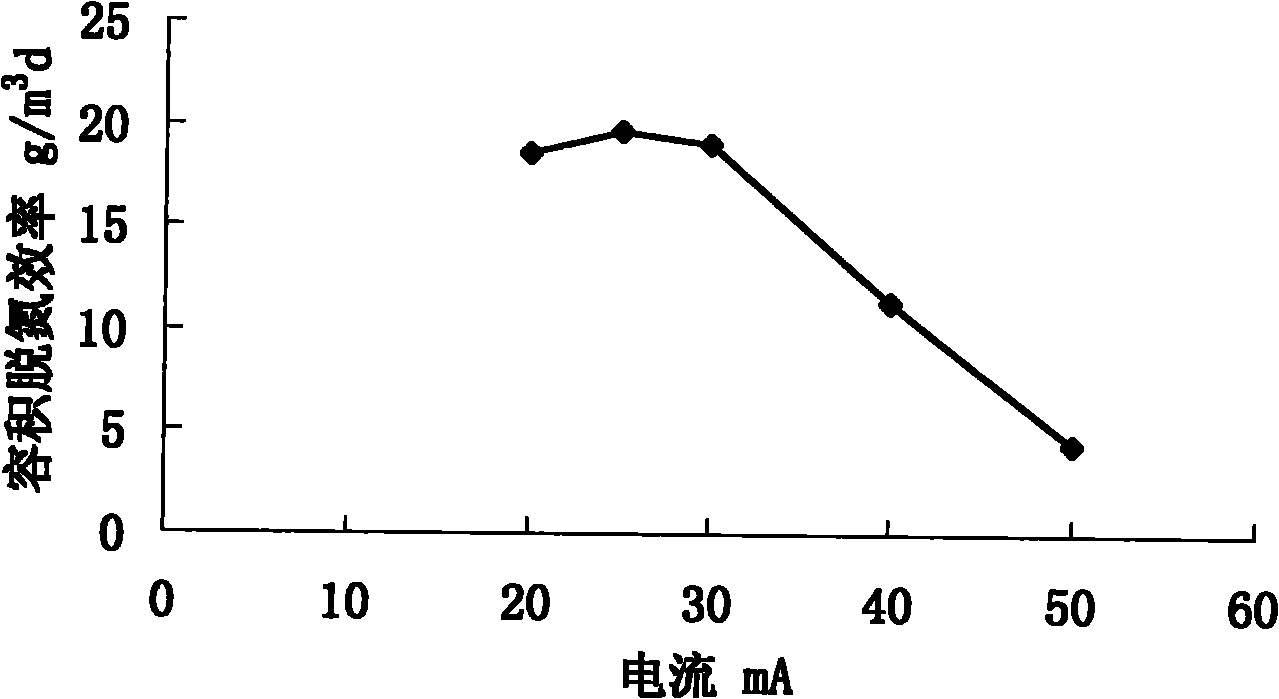

[0022] The simulated wastewater with COD 45mg / L and ammonia nitrogen 30mg / L is directly treated by complex three-dimensional electrode-biofilm reactor. Under the conditions of temperature 25-30°C and pH 7.2-7.8, the same concentration of sludge was inoculated in six reactors (No. 1, No. 2, No. 3, No. 4, No. 5, No. 6).

[0023] Then, acclimation was carried out in the 6 ways shown in Table 1, and acclimatization was carried out for 20 days. During the acclimatization process, 2 / 3 of the culture medium was replaced every day (calculated as HRT=8h). figure 2After 20 days, the volumetric denitrification efficiencies of the six acclimatization methods are shown. The results showed that with the increase of current, the denitrification efficiency also increased; under the condition of acclimatization to the same current, the volumetric denitrification efficiency by increasing the current gradually was higher than that by acclimating with a constant current.

[0024] Table 1 Sludg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com