Method for preparing calcium carbonate microspheres

A technology of calcium carbonate and microspheres, applied in the field of materials, can solve the problems of inability to effectively regulate the structure and morphology of calcium carbonate, regulation of silk fibroin nanostructures, unsuitable for large-scale production, etc., achieving easy control, simple preparation method, Size controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The silk in 0.5% Na 2 CO 3 Cook in the solution at 100°C for 60 minutes to remove sericin on the outside of the silk, rinse with deionized water, repeat 3 times, and dry at 60°C to obtain pure silk fibroin. 1g of silk fibroin was dissolved in 10mL ternary solution (by CaCl 2 / water / ethanol molar ratio is 1: 8: 2), and this silk fibroin solution is packed in dialysis bags and immersed in deionized water for dialysis for 4 days, during which the water is changed every two hours to remove CaCl in the solution 2 And ethanol, thereby obtain pure silk fibroin solution, its concentration is 2%.

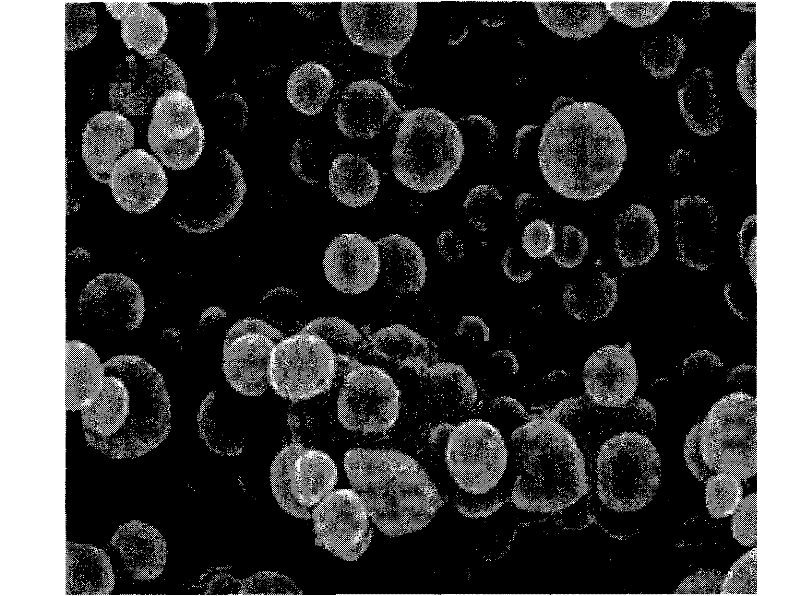

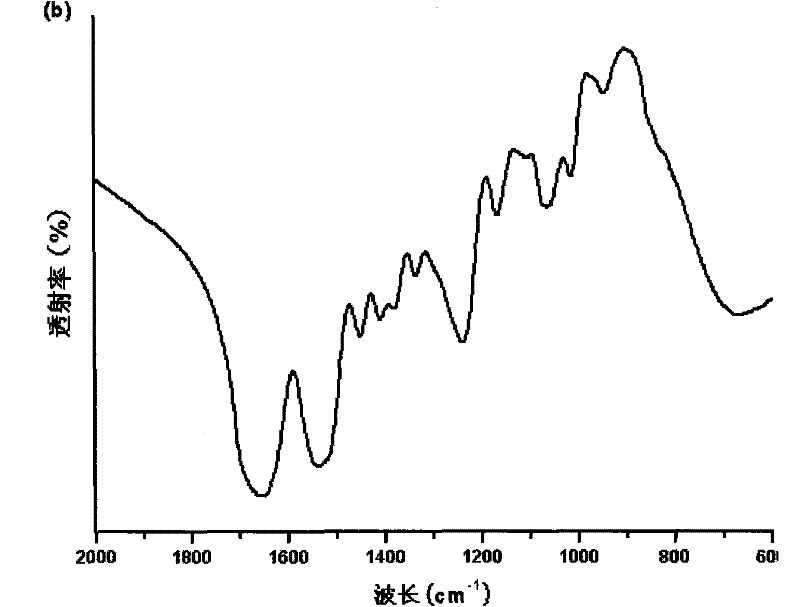

[0029] Concentrate the solution to 10%, incubate at 50°C for 6 hours, dilute it back to 0.8%, take 15mL and put it in a container with electrodes, turn on the power supply and apply a voltage of 50V to build a field strength of 3×10 3 Oriented electric field of V / m, energized for 5 minutes, silk fibroin self-assembles under the action of electric field to form silk fibroin nanop...

Embodiment 2

[0032] The silk in 0.5% Na 2 CO 3 The solution was boiled at 100°C for 60 minutes to remove sericin on the outside of the silk, rinsed with deionized water, repeated three times, and dried at 60°C to obtain pure silk fibroin. 1g of silk fibroin was dissolved in 10mL ternary solution (by CaCl 2 / water / ethanol molar ratio is 1: 8: 2), and this silk fibroin solution is packed in dialysis bags and immersed in deionized water for dialysis for 4 days, during which the water is changed every two hours to remove CaCl in the solution 2 And ethanol, thereby obtain pure silk fibroin solution, its concentration is 2%.

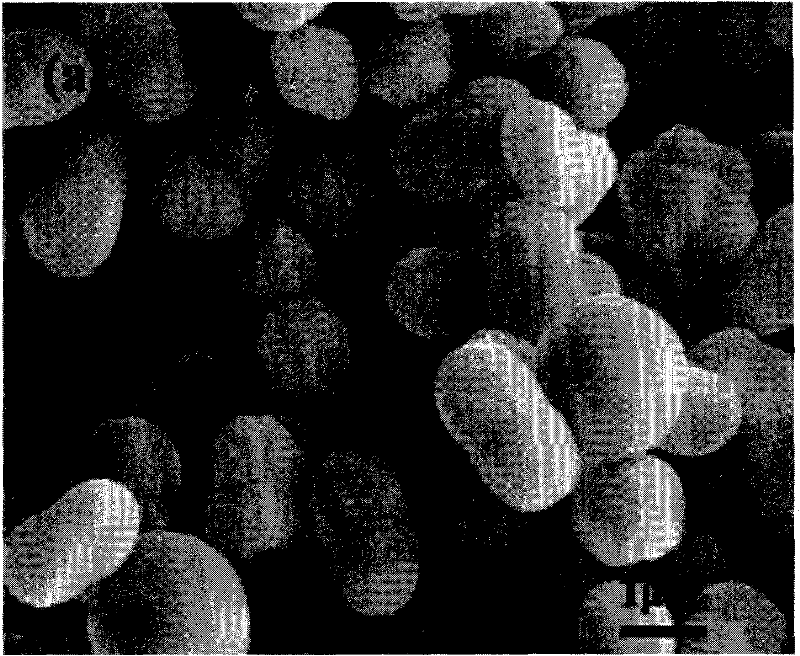

[0033] Concentrate the solution to 10%, incubate at 70°C for 6 hours, dilute it back to 2% concentration, take 15mL and put it in a container with electrodes, turn on the power supply and apply a voltage of 20V, and build a field strength of 1×10 3 A directional electric field of V / m is applied for 30 minutes to form a gel-like substance, which is freeze-dried at a t...

Embodiment 3

[0036] The silk in 0.5% Na 2 CO 3 Cook in the solution at 100°C for 60 minutes to remove sericin on the outside of the silk, rinse with deionized water, repeat 3 times, and dry at 60°C to obtain pure silk fibroin. 1g of silk fibroin was dissolved in 10mL ternary solution (by CaCl 2 / water / ethanol molar ratio is 1: 8: 2), and this silk fibroin solution is packed in dialysis bags and immersed in deionized water for dialysis for 4 days, during which the water is changed every two hours to remove CaCl in the solution 2 And ethanol, thereby obtain pure silk fibroin solution, its concentration is 2%.

[0037] The solution was sealed and incubated at 40°C for 36 hours, 15mL was taken and placed in a container with electrodes installed, the power was turned on and a voltage of 35V was applied to build a field strength of 3.5×10 3 V / m directional electric field, electrified for 5 minutes, silk fibroin self-assembles under the action of electric field to form silk fibroin nanopart...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com