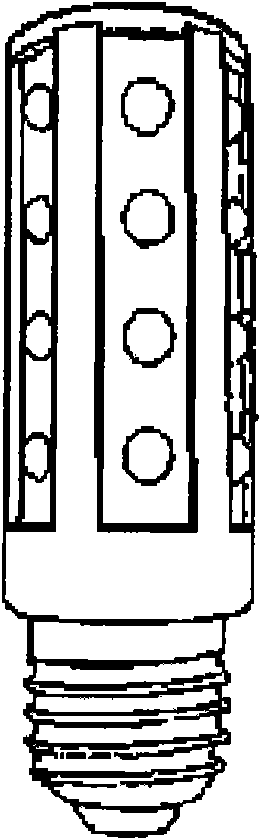

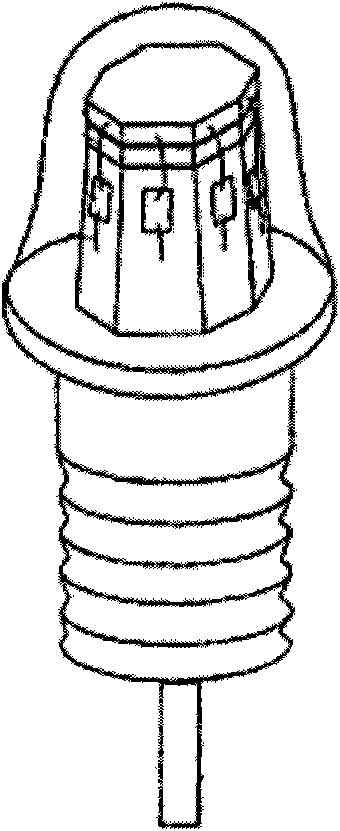

Space omnidirectional light-emitting diode (LED)

An omnidirectional and spatial technology, applied in the direction of light source, electric light source, light source fixation, etc., can solve the problems of uneven light intensity distribution, difficult control of bracket surface coating, difficult to large-scale production, etc., to achieve flexible and changeable structure and appearance. , The light distribution has no dead angle, and the design is convenient and flexible.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

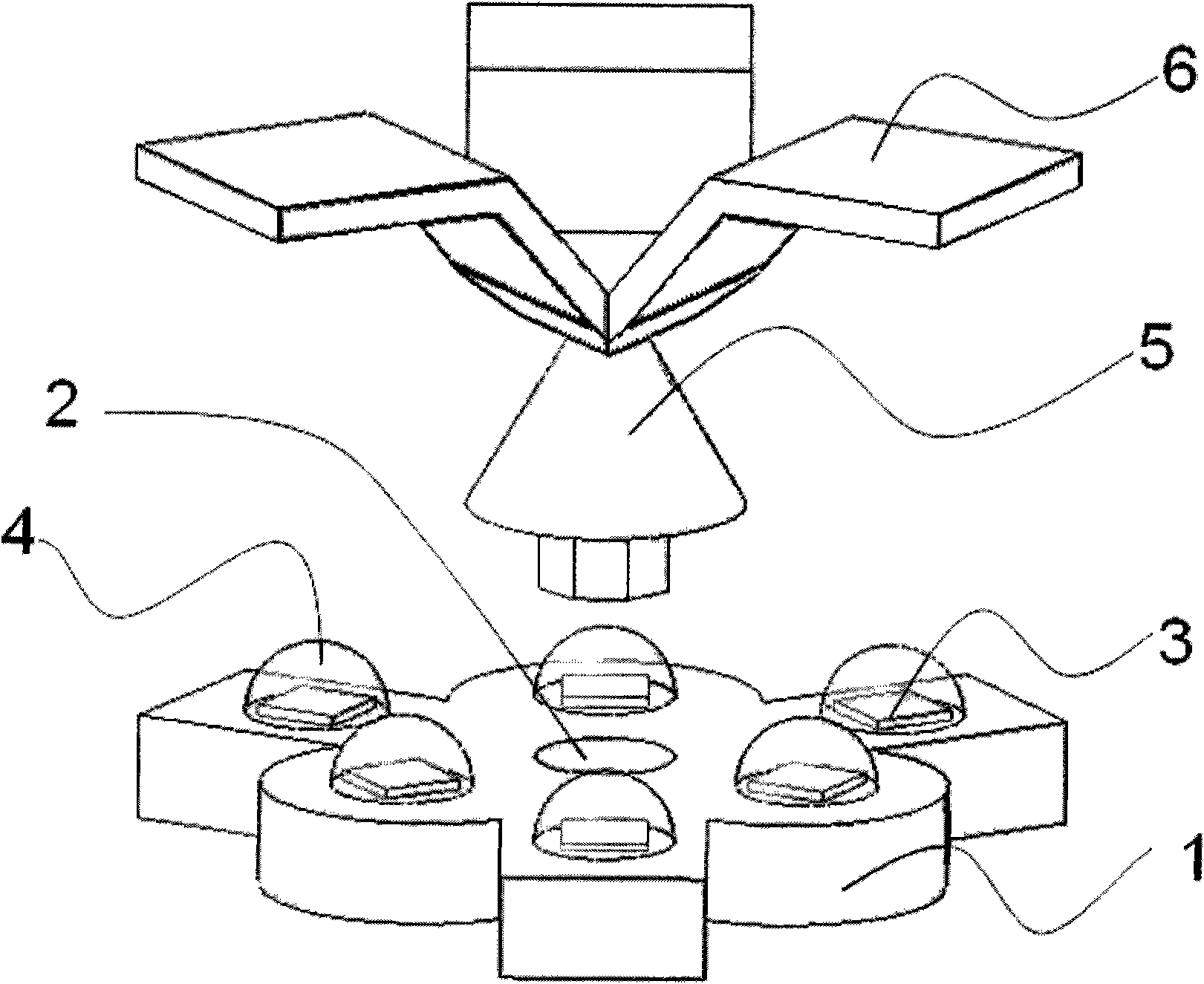

[0031] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples, so that the realization process of how to use technical means to solve technical problems and achieve technical effects in the present invention can be fully understood and implemented accordingly.

[0032] The core of the present invention includes:

[0033] 1) The forward light output of the chip and the reflected light of the reflective device form a spatial light distribution;

[0034] 2) The light-emitting chips are distributed on the same plane in an equiangular circular array;

[0035] 3) The reflective device is composed of a support body and multiple reflective leaf surfaces, and the reflective leaf surfaces are designed with multiple angles to the horizontal direction.

[0036] A space omnidirectional light-emitting LED of the present invention comprises: a substrate, an LED light-emitting chip, a colloid, a support body, and a reflecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com