A flat 180° light-emitting patch led

A technology of LED chips and planes, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems affecting the uniformity of emitted light, the thickness of SMD LEDs, and the poor uniformity of light, so as to improve the diffuse reflection effect and reduce the Thickness, the effect of reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the examples, but not as a basis for limiting the present invention.

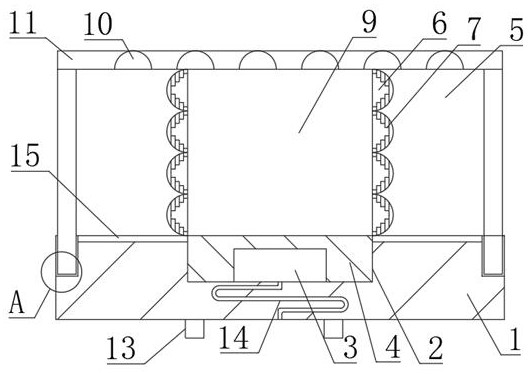

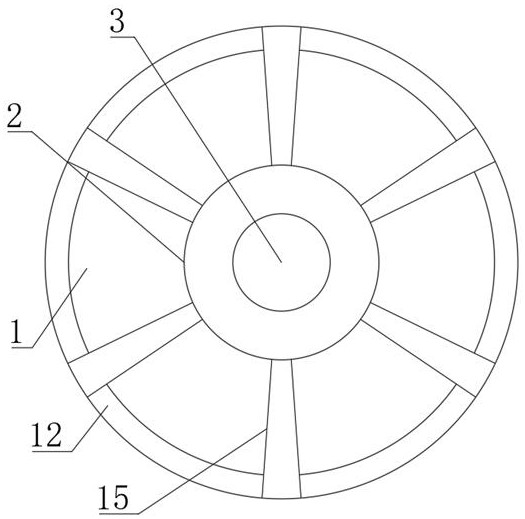

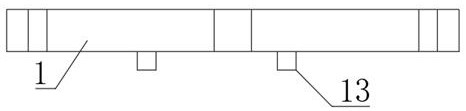

[0019] Example. A flat 180° light-emitting SMD LED, constituted as Figures 1 to 4 As shown, including the bracket 1, the middle part of the bracket 1 is provided with a bowl cup 2; the circumference of the bowl cup 2 is provided with a plurality of uniformly distributed radioactive lines 15, and the bowl cup 2 is provided with LED chips 3, and the bowl cup 2 is provided with LED chips 3. Filled with optical glue 4; the top of the bracket 1 is coated with a diffusion layer 5, and the position of the bowl cup 2 on the diffusion layer 5 is provided with a light outlet 9; There are diffuse reflection grooves 6, and a plurality of protrusions 7 are annularly distributed in each diffuse reflection groove 6; a light outlet is provided at a position corresponding to one end of each radial pattern 15 on the side of the support 1.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com