Energy efficient fixture method for anchor nail

A fixing method and technology of anchoring nails, applied in the direction of furnace types, furnaces, heat treatment equipment, etc., to achieve the effects of reducing heat loss, improving work efficiency, and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

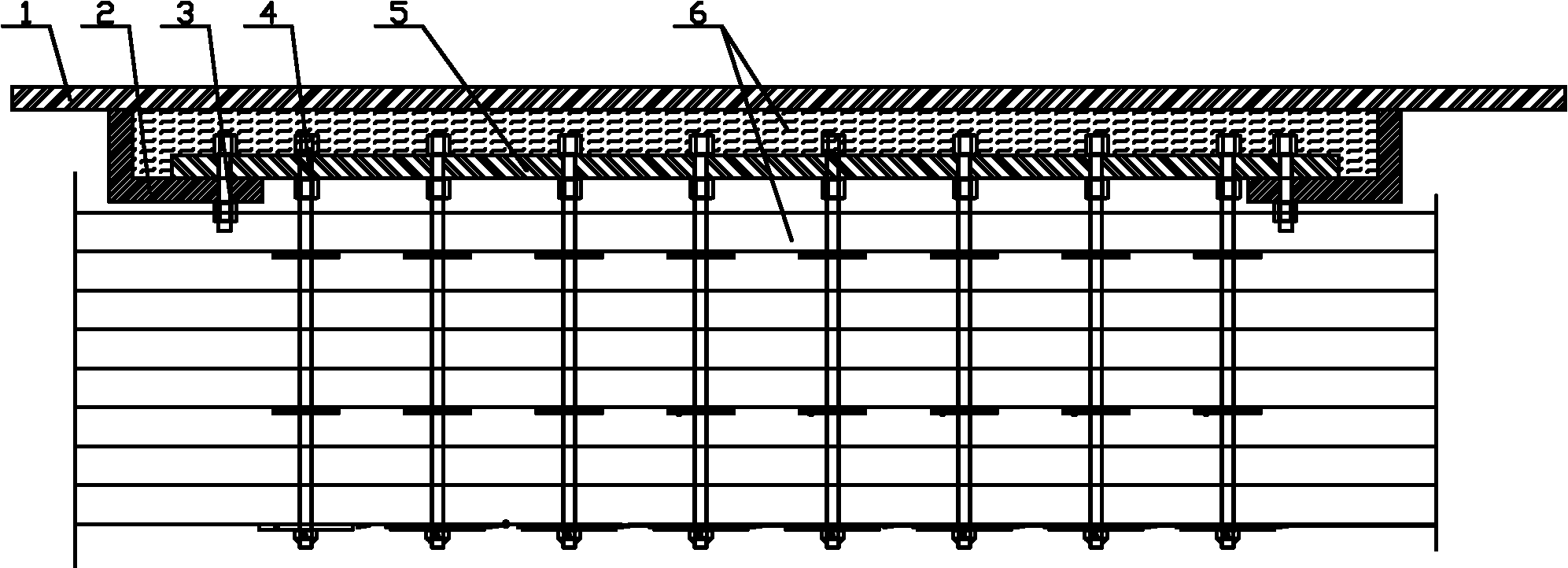

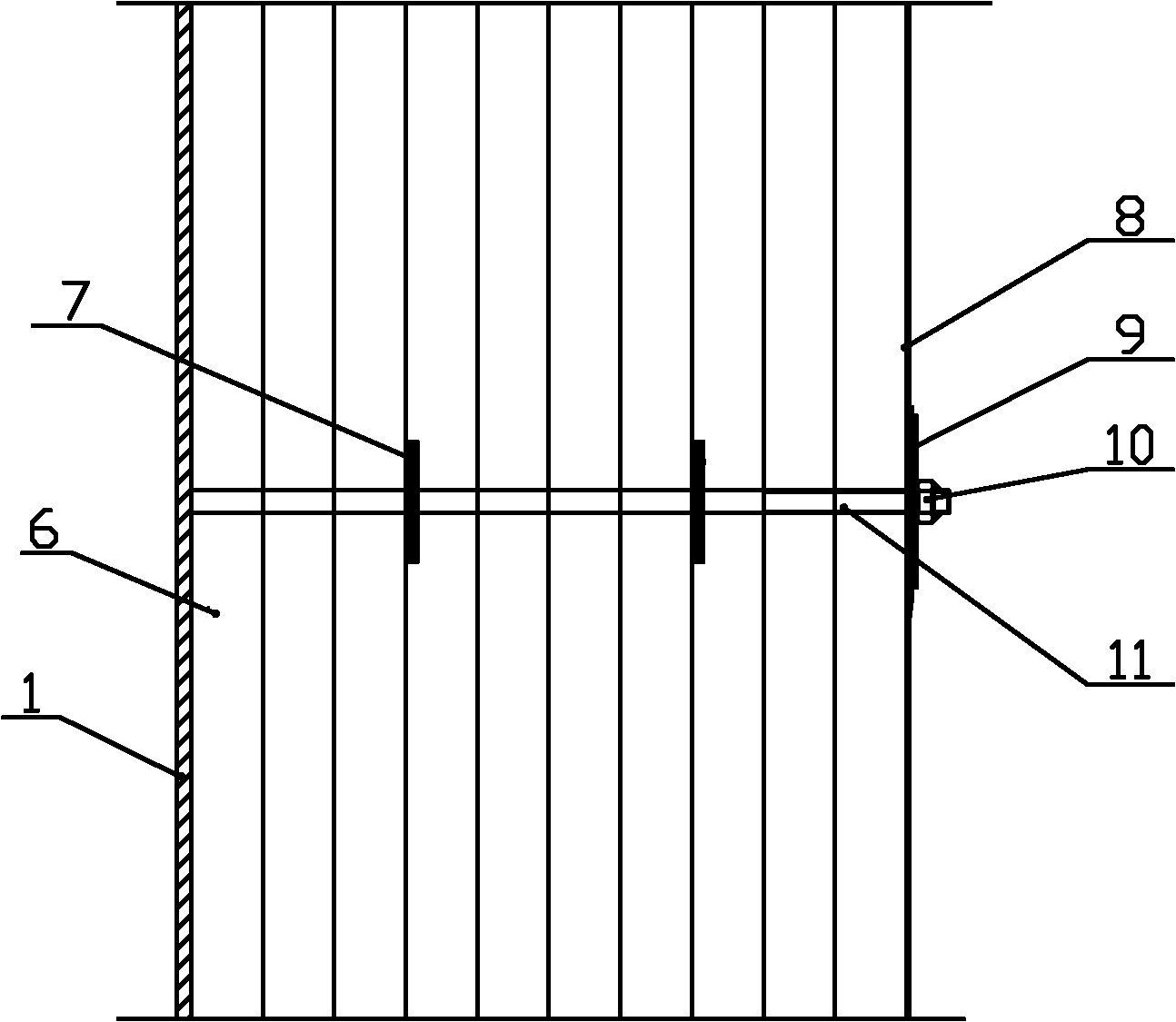

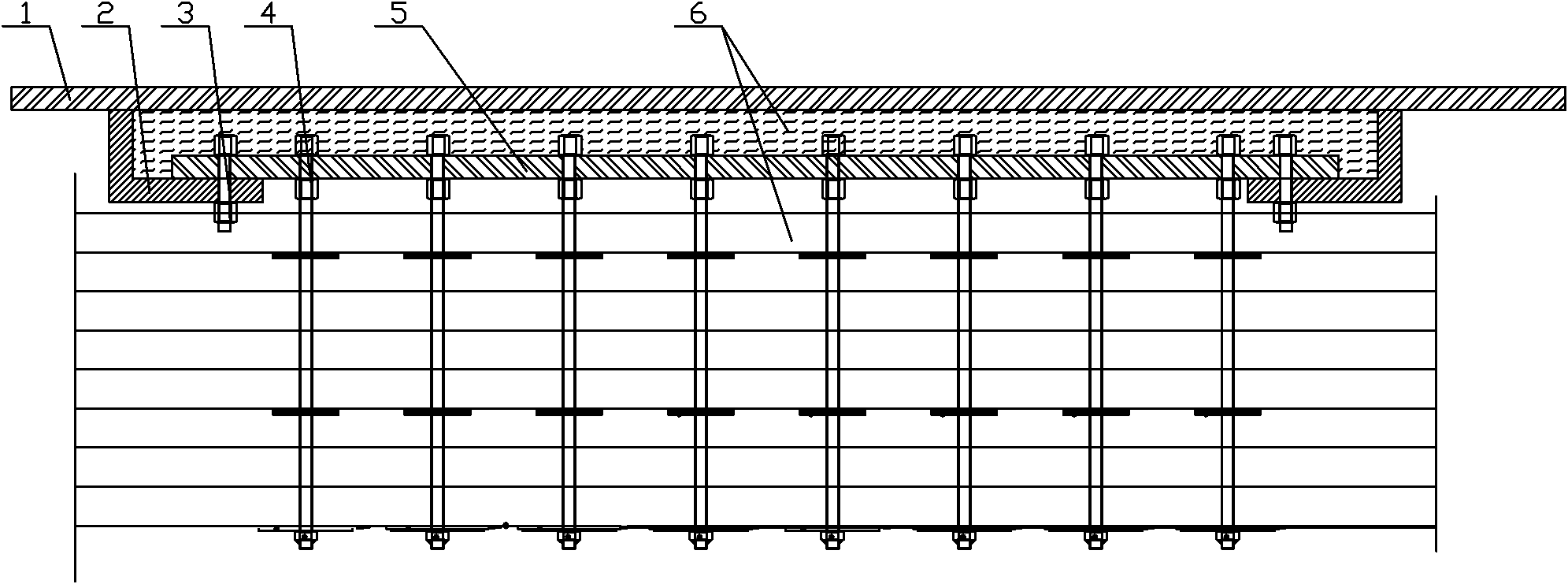

[0026] The energy-saving fixing method of the anchor nail provided by the present invention is as follows: first, the anchor L-shaped steel plate 2 is welded on the furnace shell, and the anchor nail is fixed through the anchor nut before the anchor steel plate 5 is installed, and then through the bolt nut Fastener 3 installs the anchoring steel plate 5 on the anchoring L-shaped plate 2, so that the rows of anchoring nails are installed; install the next row of anchoring nails according to the above steps until the entire furnace is filled, and then install the refractory fiber 6, Realize fixing the refractory fiber 6 on the furnace wall steel plate 1 of the vertical continuous annealing furnace.

[0027] see figure 1 , the present invention specifically adopts the method comprising the following steps:

[0028] The first step is to weld and anchor the L-shaped steel plate part 2 on the furnace wall steel plate 1;

[0029] In the second step, a plurality of anchor nails are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com