Enzymatic on-site deep acidizing fluid for oil and gas fields and application thereof

A technology of deep acidification and acidification solution, applied in chemical instruments and methods, drilling composition and other directions, can solve the problems of difficult to meet engineering conditions, short effective acid etching distance, corrosion of construction equipment, etc., to improve the acidification effect. and crude oil and natural gas recovery, improve formation permeability, avoid corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

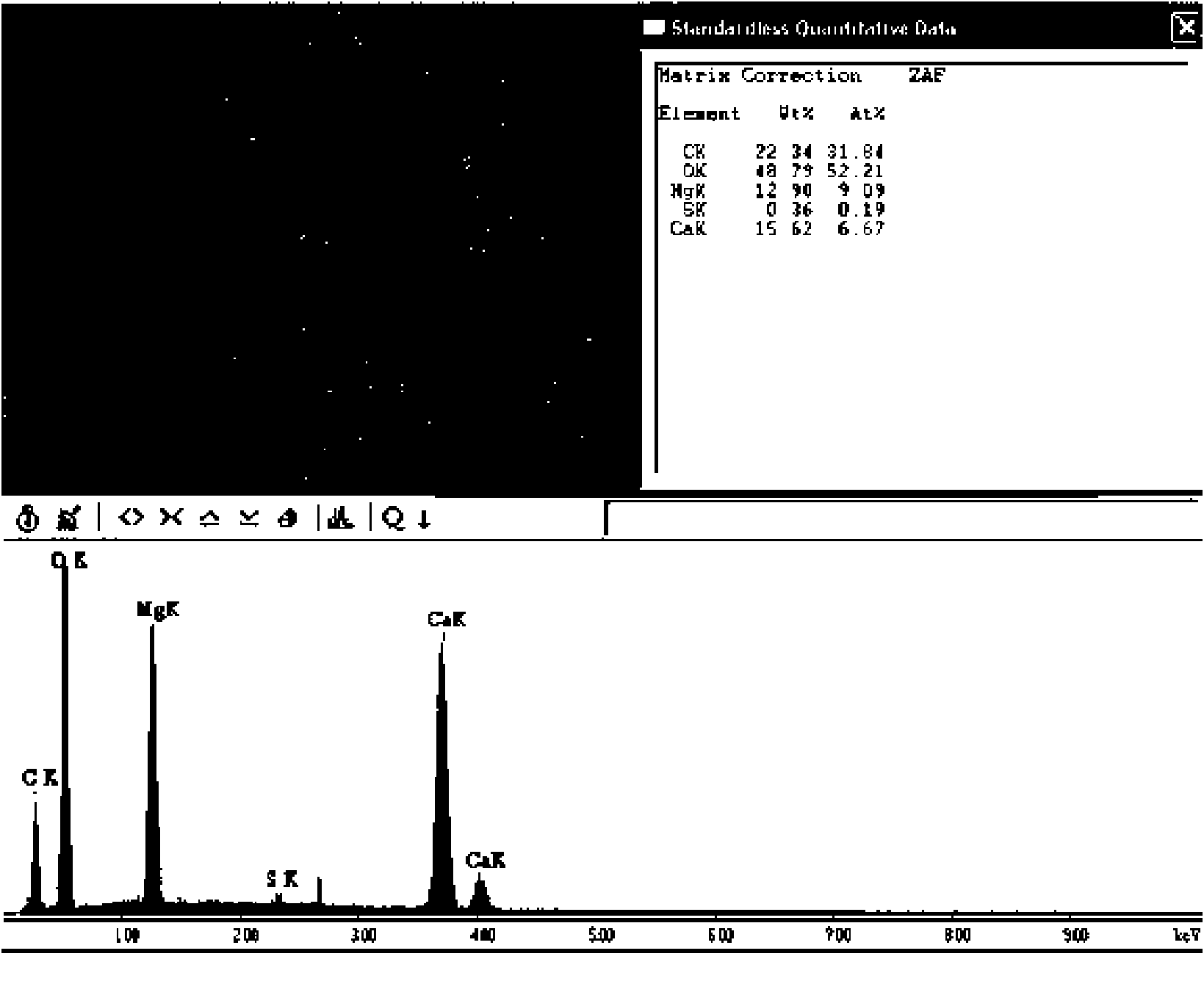

[0049] In situ acid corrosion test without lipase catalysis: 25% methyl lactate (36 g, 0.10 mol) was added to a 100 mL reaction flask filled with 20.00 g of anhydrous calcium carbonate (0.2 mol). The reaction mixture was heated at 100°C for 5 hours, cooled to room temperature, filtered through a pre-weighed sand core funnel, unreacted calcium carbonate was washed three times with water, drained and then dried in an oven at 110°C to constant weight. Unreacted calcium carbonate weighed 19.32g. According to the theoretical calculation, the corrosion rate is 6.7%.

Embodiment 2

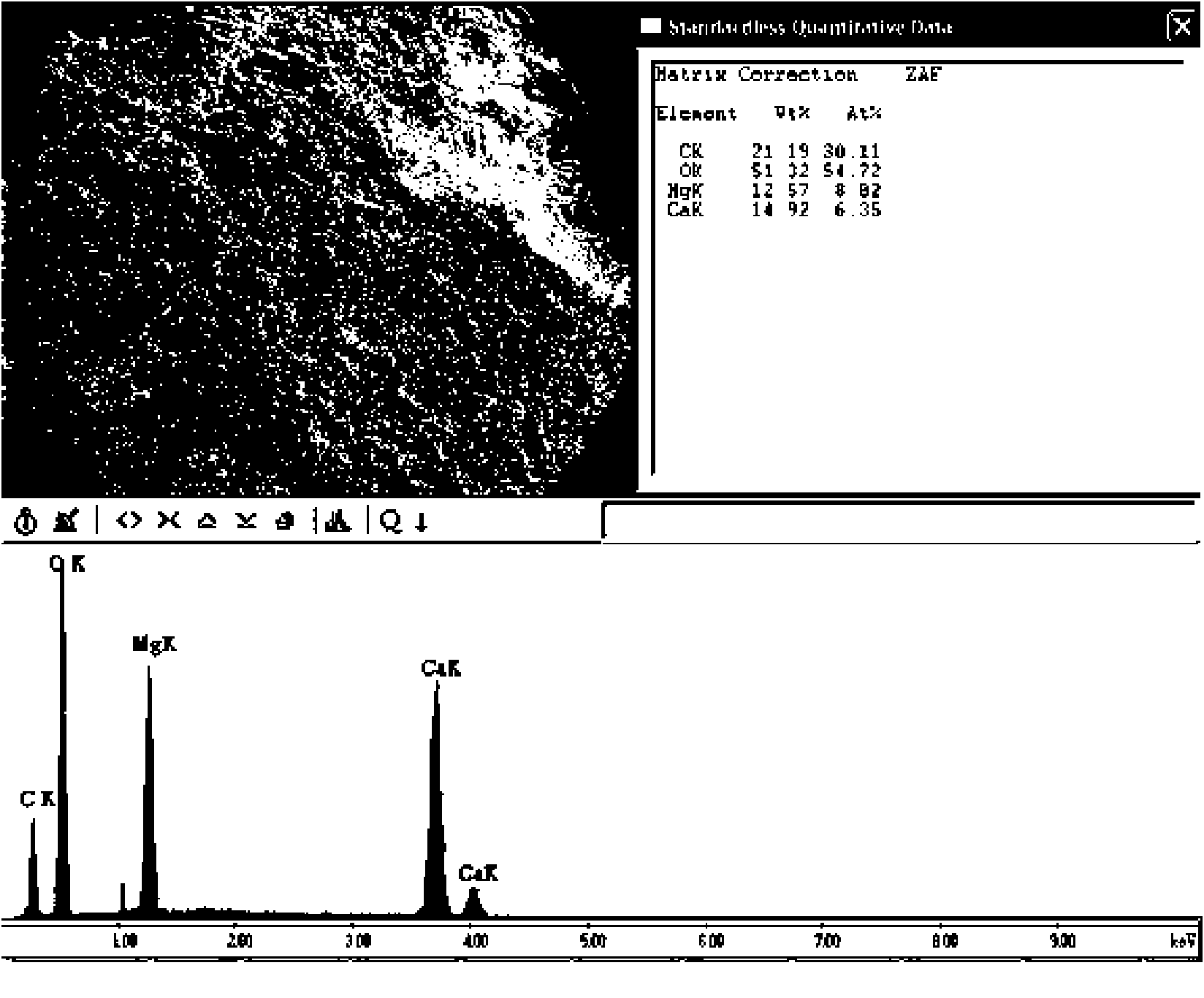

[0051] Lipase catalyzed acid corrosion test in situ: add 25% methyl glycolate (36g, 0.10mol) to the 100mL reaction flask filled with 20.00g anhydrous calcium carbonate (0.2mol), then add lipase (0.002%, w / v). The reaction mixture was heated at 100°C for 4 hours, cooled to room temperature, filtered through a pre-weighed sand core funnel, unreacted calcium carbonate was washed three times with water, drained and then dried in an oven at 110°C to constant weight. Unreacted calcium carbonate weighed 12.1 g. According to the theoretical calculation, the dissolution rate is 79%.

Embodiment 3

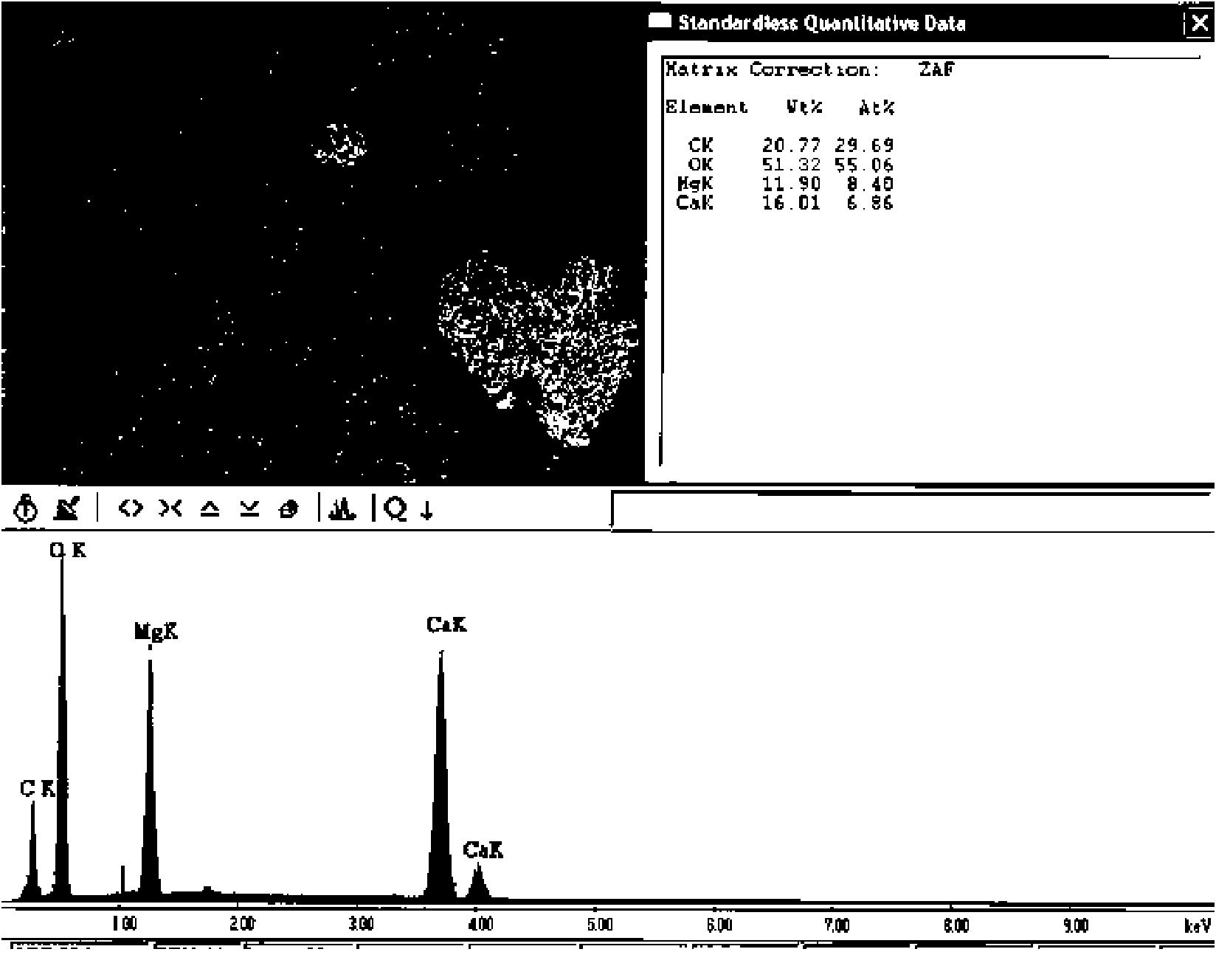

[0053] Thermophilic lipase catalyzed acid corrosion test in situ: add 25% methyl lactate (41.6g, 0.10mol) to the 100mL reaction flask filled with 20.00g anhydrous calcium carbonate (0.2mol), then add lipase (0.002 %, w / v). The reaction mixture was heated at 100°C for 14 hours, cooled to room temperature, filtered through a pre-weighed sand core funnel, unreacted calcium carbonate was washed three times with water, drained and then dried in an oven at 110°C to constant weight. Unreacted calcium carbonate weighed 10.3 g. According to the theoretical value, the corrosion rate is 97%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com