Synthesis method of bimodal-distribution ethylene-alpha-alkene-non-conjugated dialkene random copolymer

A non-conjugated diene, ethylene-propylene copolymer technology is applied in the field of synthesis of bimodal ethylene-α-olefin-non-conjugated diene random copolymers, and can solve the tunability of ethylene-propylene copolymer monomers It is not as good as other problems to achieve the effect of moderate molecular weight distribution and high Mooney viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

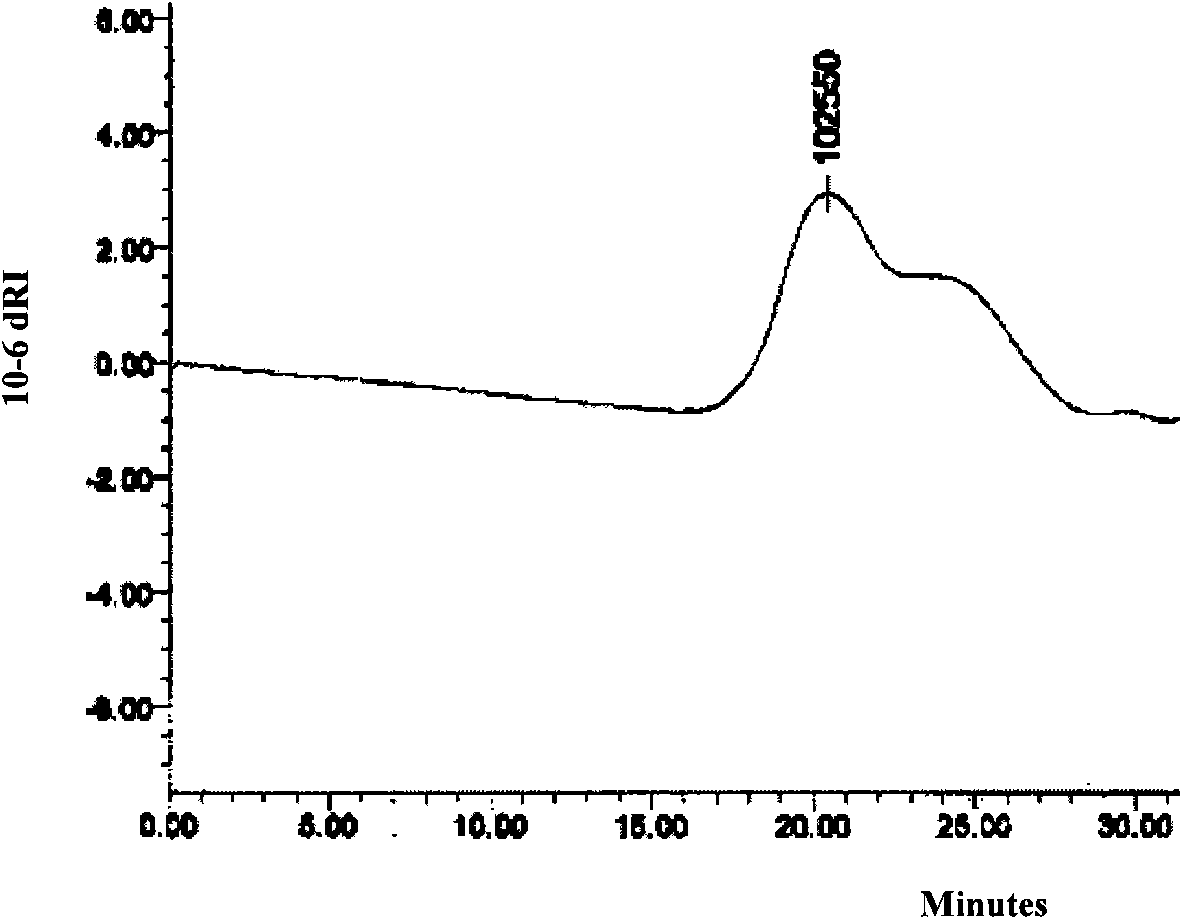

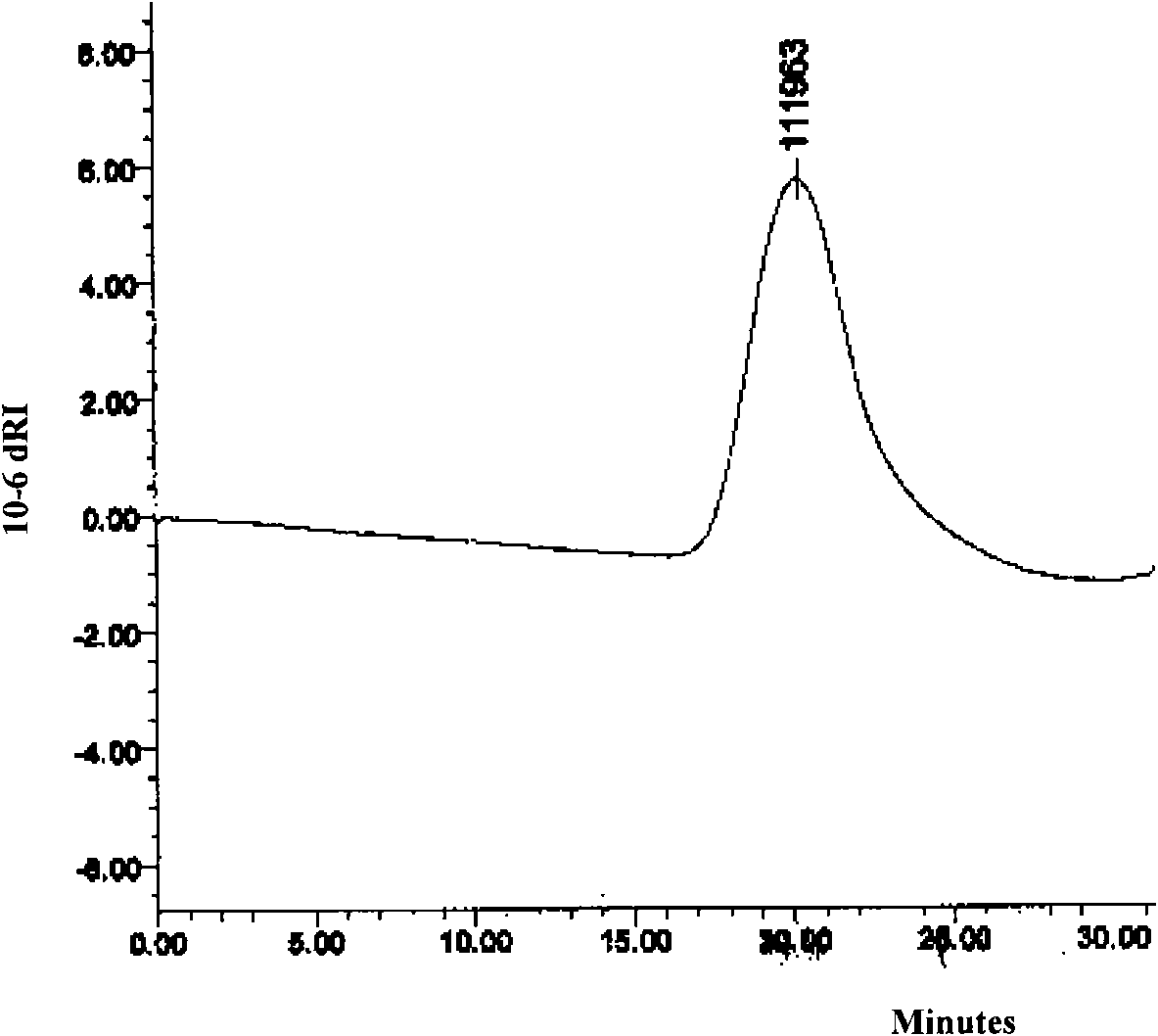

Examples

Embodiment 1

[0032] Synthesis of Soluble Vanadium Complex Catalyst

[0033] Take a 100ml bottle with an inlet tube at the bottom, two-corner ground mouth bottle, conduct anhydrous and anaerobic treatment under vacuum and heating, then add 50ml of dry hexane, inject high-purity nitrogen for bubbling, and then use dry medical glass Add 1ml (0.0105mol) vanadyl trichloride into the needle tube, stir for 10 minutes, then slowly drop in 0.0158mol of di-isooctyl phosphate diluted with 5ml of hexane, while bubbling high-purity nitrogen gas, the reaction stops after 30 minutes , to obtain a soluble vanadium complex catalyst solution with a concentration of 0.2 mol / L, seal the reaction vessel and store it away from light.

Embodiment 2

[0035]The preparation of high molecular weight partial ethylene-propylene copolymer is carried out in the first reactor. Prepare ethylene, propylene, and hydrogen through a mixing device at a ratio of 1:2:0.15, and then fully mix them evenly through a circulating compressor. Oxygen treatment for 1 hour, the inert gas used is high-purity nitrogen, then add 2000ml of dry hexane (water content≤10ppm) to it, which contains 4ml of norbornene (ENB), open the circulation compressor, and feed into the polymerization tank Mixed gas, the mixed gas flow rate is 150L / hour, the mixed gas dissolved in hexane reaches saturation, then add 1ml (0.2mmol) of soluble vanadium complex catalyst hexane solution successively, add sesquialuminum, make Al / V The ratio is 10 / 1, the polymerization temperature is 30°C, the polymerization pressure is 0.5MPa, and the polymerization reaction time is 1 hour. After the polymerization reaction is completed, the glue is released from the bottom pipe of the polyme...

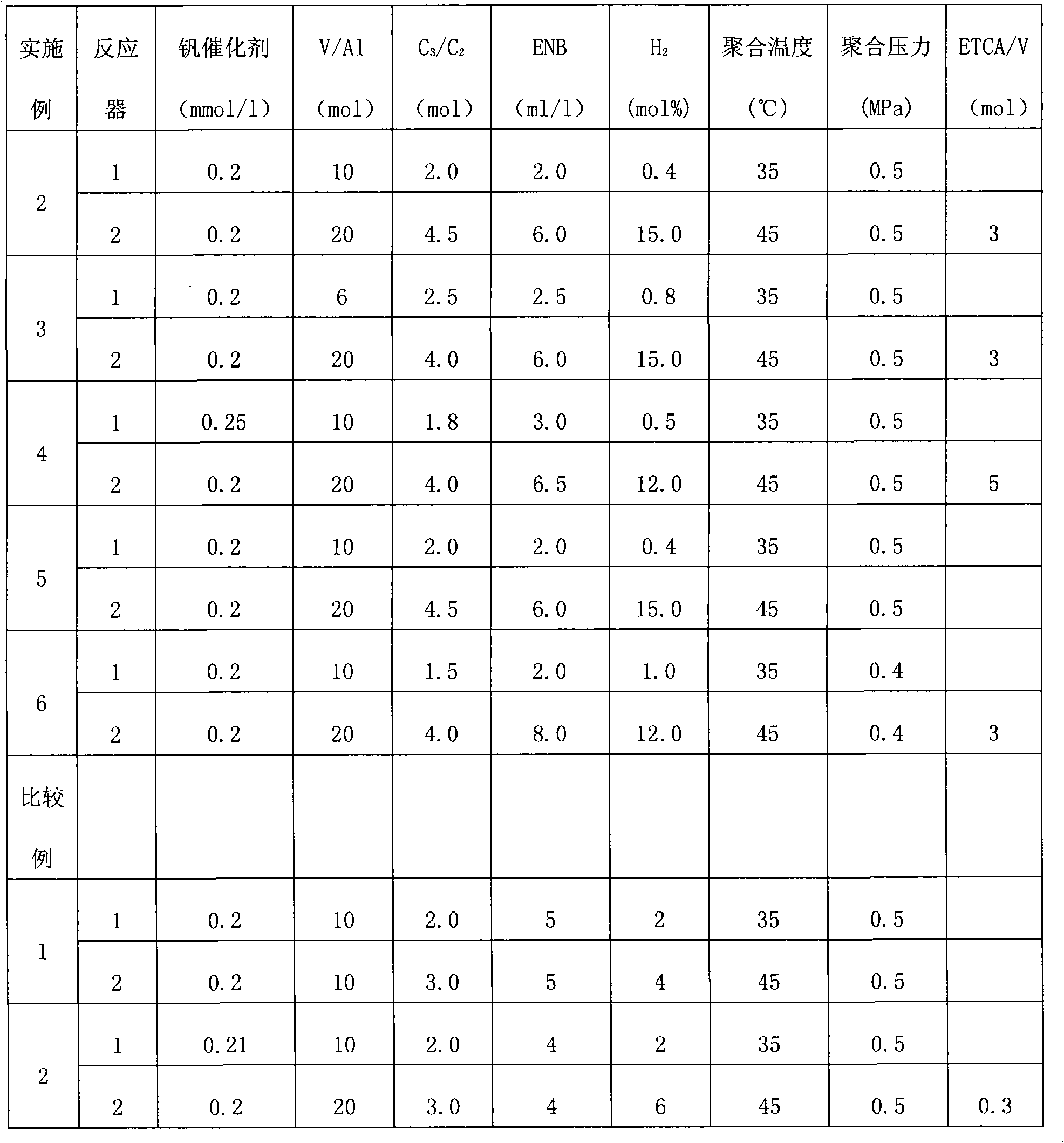

Embodiment 3-6

[0039] The polymerization operation process is the same as in Example 1, and the other conditions are shown in Table 1, and the analysis results are shown in Table 2. The blending results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average relative molecular mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com