Laser three-dimensional inside engraving machine having USB master-slave dual-mode functions

A laser three-dimensional, internal engraving machine technology, applied in the field of engraving controllers, can solve the problems of inability to read directly by USB mobile storage devices, low real-time performance of Windows platform, and time function can only reach millisecond level, etc. The effect of stable processing and improved compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

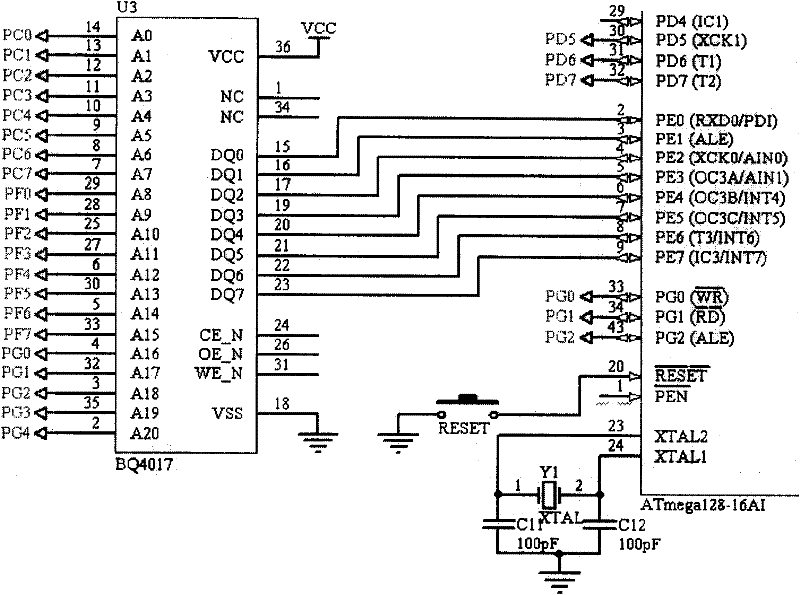

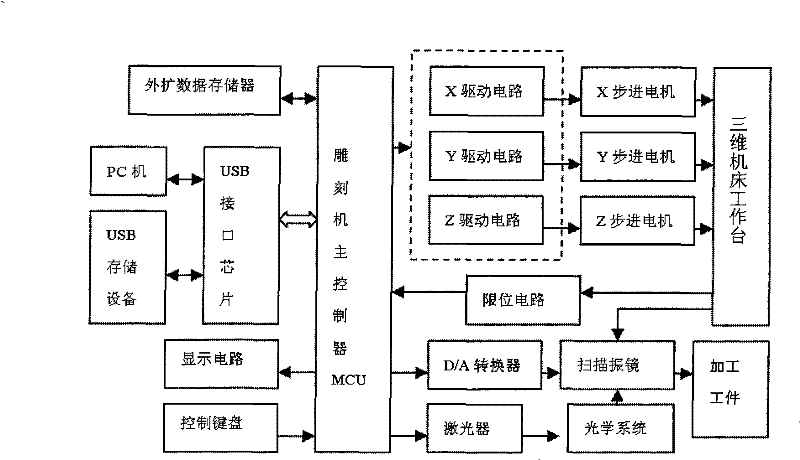

[0024] Such as figure 1 As shown, a laser three-dimensional internal engraving machine with USB master-slave dual-mode function, the internal engraving machine includes a PC host module, a USB communication module, a large-capacity data storage module, a scanning galvanometer control module, a three-dimensional processing machine tool control module, The laser control module, the human-computer interaction module and the main controller of the internal engraving machine are respectively connected to the USB communication module, the large-capacity data storage module, the scanning galvanometer control module, the three-dimensional processing machine tool control module, and the laser Control module and human-computer interaction module.

[0025] The main modules are implemented in the following ways:

[0026] (1) USB communication module, full-speed USB interface, compatible with USB V2.0, composed of AVR single-chip microcomputer and USB interface chip. There is an independ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com