Production method and device of copper tube used by conductive nozzle

A production method and the technology of the contact tip, which are applied in the direction of the mandrel, etc., can solve the problem that it is difficult to accurately control the deviation of the inner diameter and roundness of the copper tube for the contact tip, it is difficult to ensure the quality and yield of the copper tube for the contact tip, and the inner diameter of the tube. Hole size accuracy is difficult to control and other problems, to achieve the effect of automatic tracking and automatic reset, solve the problem of loading, high surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

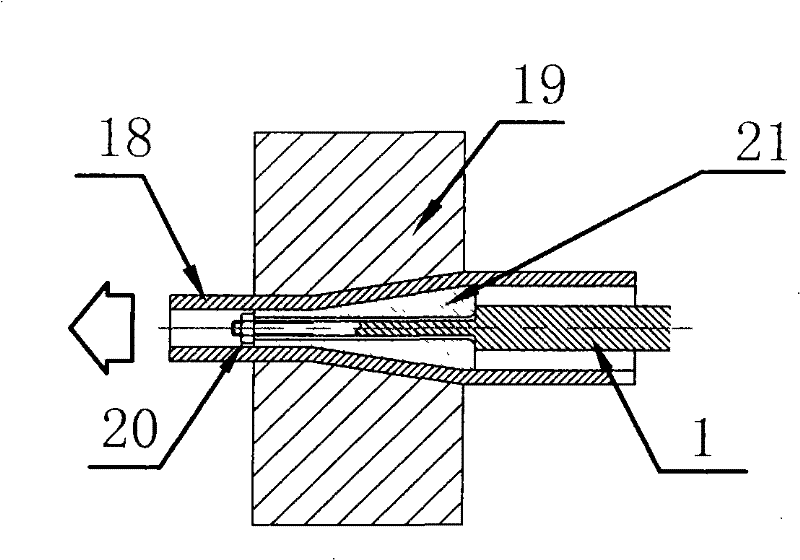

[0031] Such as figure 1 As shown, the fixed core head stretching method in the prior art is that the fixed core head 21 working in the drawing die 19 is connected with the fixed core rod 1 by the nut 20 . Since the size of the fixed mandrel 1 at the connection is always smaller than the outer diameter of the fixed mandrel 21, when the outer diameter of the fixed mandrel 21 is small to a certain size, the fixed mandrel 1 is caused by too small a cross-sectional dimension at the joint. The strength is not enough to realize the stretching of the copper tube for the contact tip.

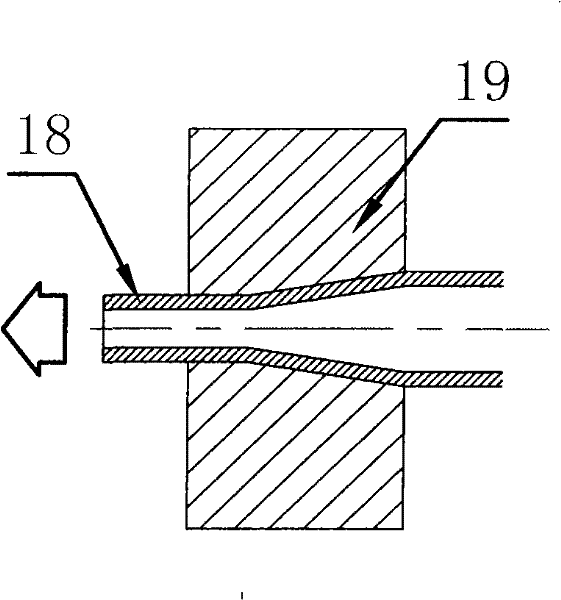

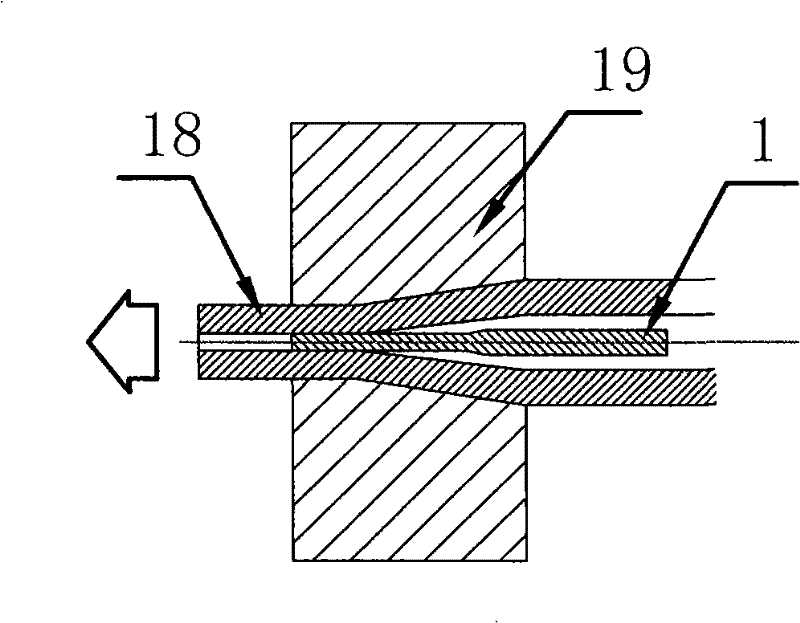

[0032] Such as figure 2 As shown, the copper tube billet is air-drawn on the existing linear tube and bar drawing machine, that is, the inner diameter of the copper tube is gradually obtained while reducing the outer diameter of the copper tube. There are two disadvantages in the production method of the copper tube for the contact tip. One is that the roughness of the inner surface of the tube deteri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com