Electrical connector

A technology for electrical connectors and docking connectors, which is applied in the directions of connections, circuits, and components of connecting devices, can solve the problems of high cost of the connector interface, complex chip design, and large size of the connector, and achieves a simple structural design. , The effect of easy design and strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

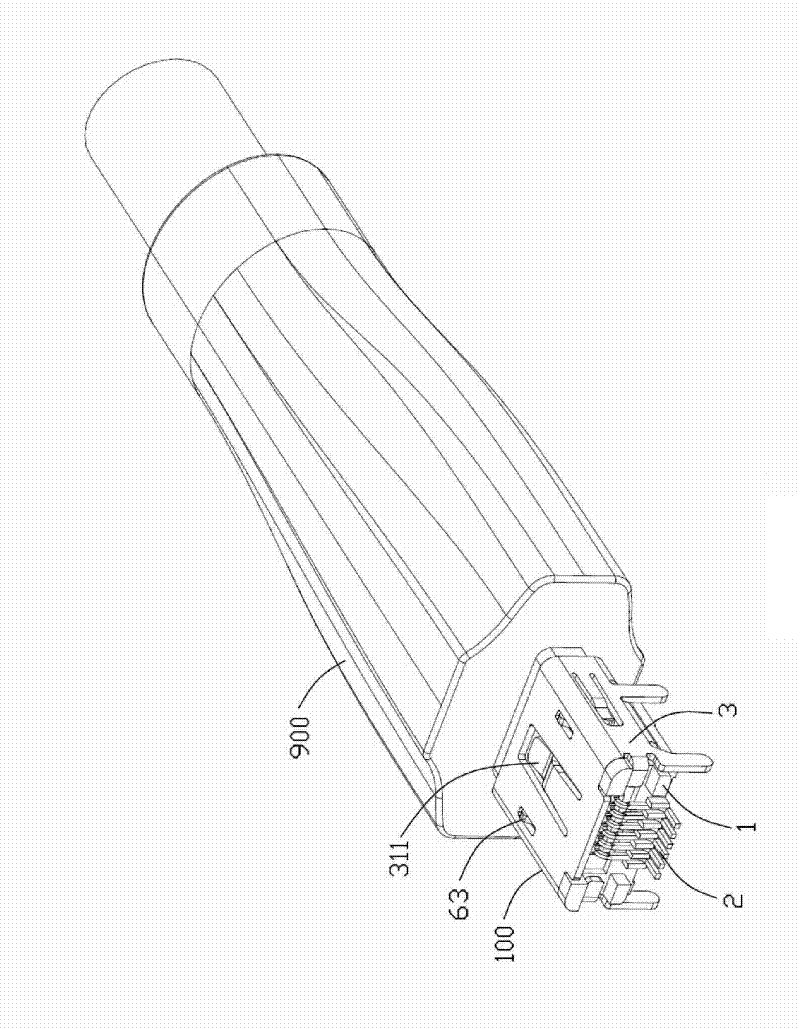

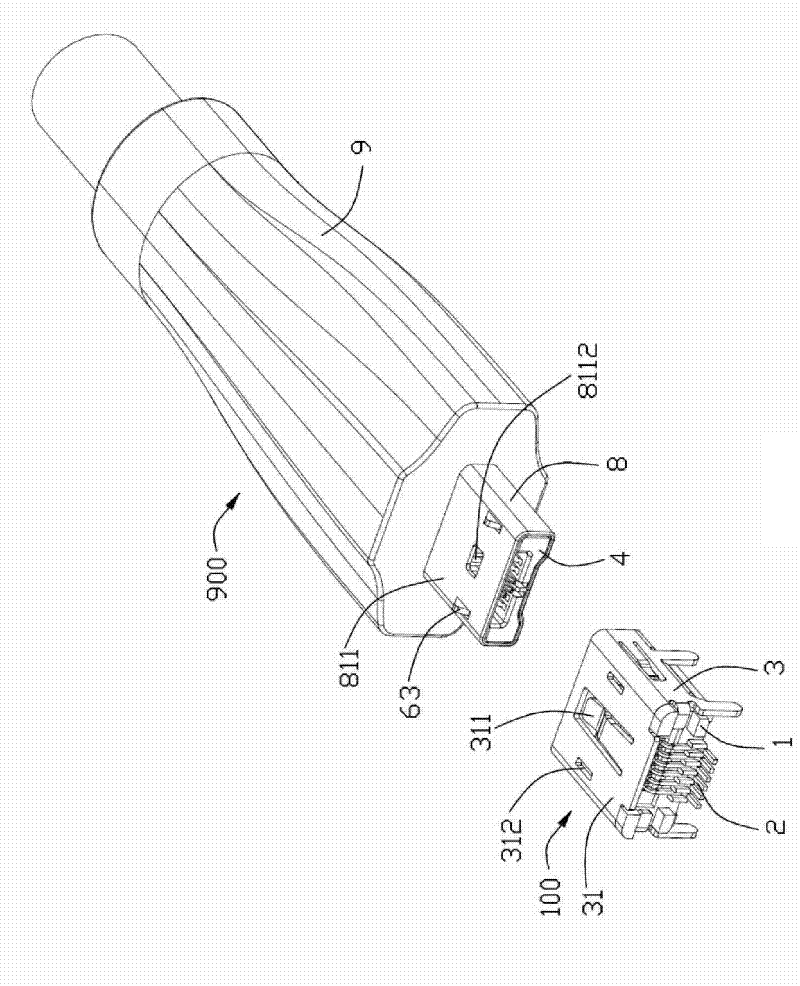

[0019] see figure 1 and figure 2 As shown, the electrical connector of the present invention includes a plug connector 900 (hereinafter referred to as the plug 900) and a socket connector 100 (hereinafter referred to as the socket 100), and the plug 900 and the socket 100 form a mutually insertable butt joint connection. device.

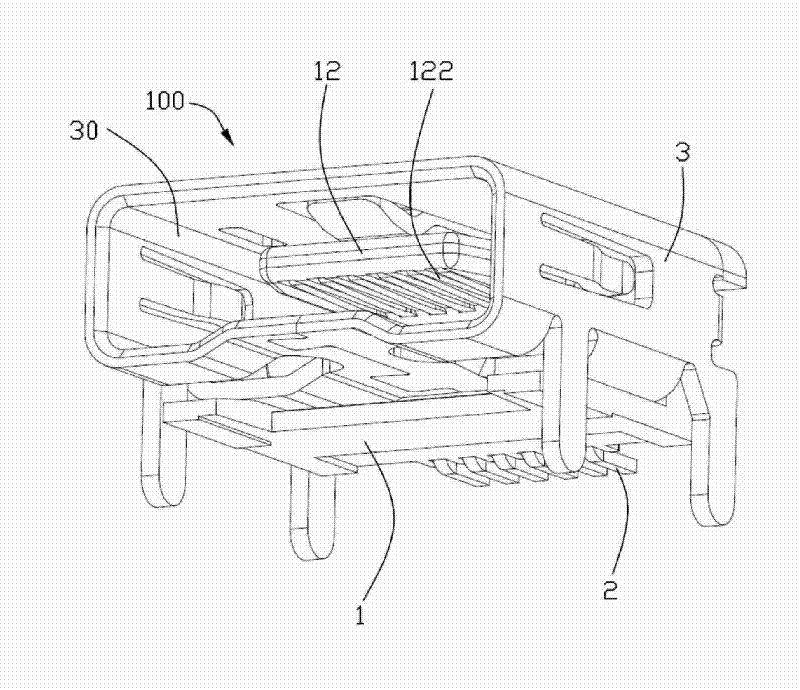

[0020] see Figure 3 to Figure 6 As shown, the socket 100 includes a first body 1, a plurality of first conductive terminals 2 held on the first body 1, and a first shielding shell 3 covering the first body 1. The first shielding shell 3 A first receiving space 30 for receiving the mating plug 900 is provided.

[0021] The first body 1 includes a first base 11 and a first tongue 12 protruding forward from the first base 11 . The first tongue 12 extends along the horizontal direction, and includes an upper surface 121 and a lower surface 122 opposite to the upper surface 121 . A protruding portion 1211 protruding upward is formed on the rear end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com