Method for diagnosing deformation of transformer winding based on frequency response characteristics

A transformer winding and diagnostic method technology, applied in the direction of instruments, measuring electrical variables, measuring devices, etc., can solve problems such as difficult specifications, difficult maintenance decisions, and differences, and achieve the effect of easy implementation and unique diagnostic results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0018] The frequency response fingerprint is to apply a sine wave voltage U with a variable frequency at one end of the transformer winding 1 , the other end of the transformer winding is connected to a resistor in series and grounded, and the voltage U will be generated on the resistor under the excitation of the voltage source 2 , put H(f)=201n(U 2 / U 1 ) with the change curve of 1kHz ~ 1MHz frequency is called the frequency response fingerprint, referred to as the frequency response fingerprint.

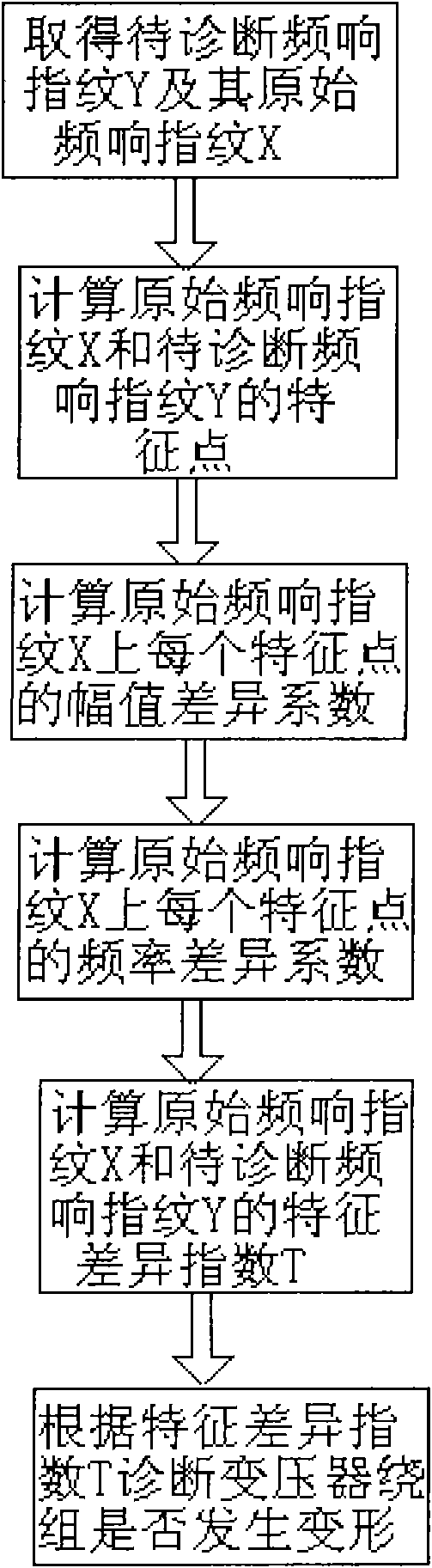

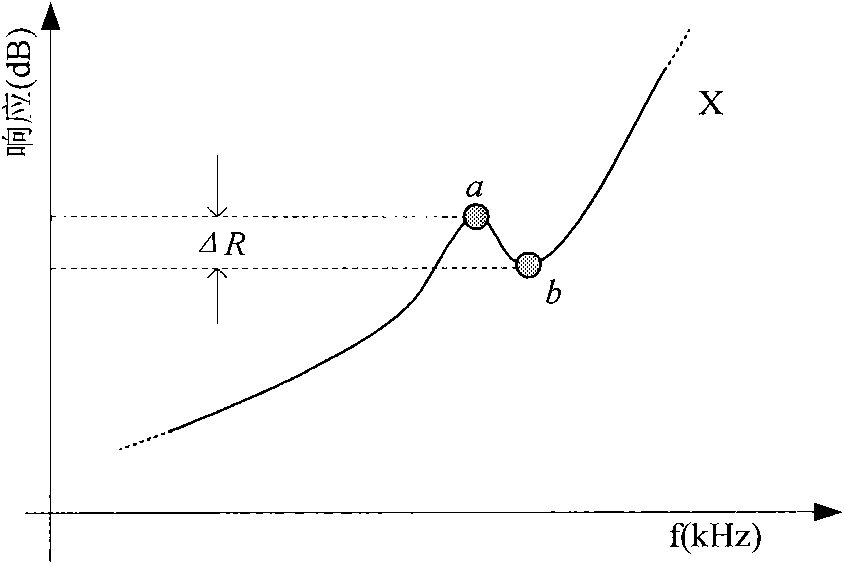

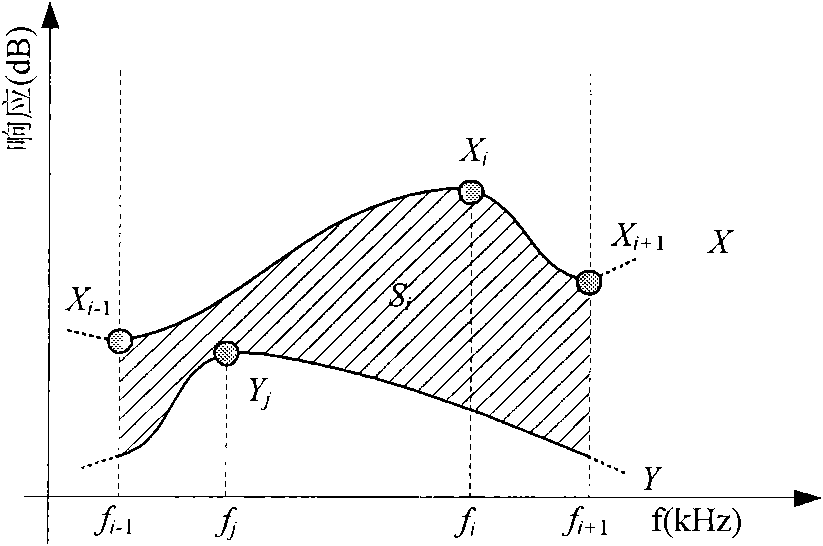

[0019] Such as figure 1 As shown, the present invention is based on a large number of extreme points related to the transformer winding structure contained in the frequency response fingerprint of the transformer winding. These extreme points are the basic characteristics of the frequency response fingerprint. When the transformer winding is deformed, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com