Gear fault diagnosis method in railway locomotive gearbox

A railway locomotive and fault diagnosis technology, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., and can solve problems such as failures that cannot be identified

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

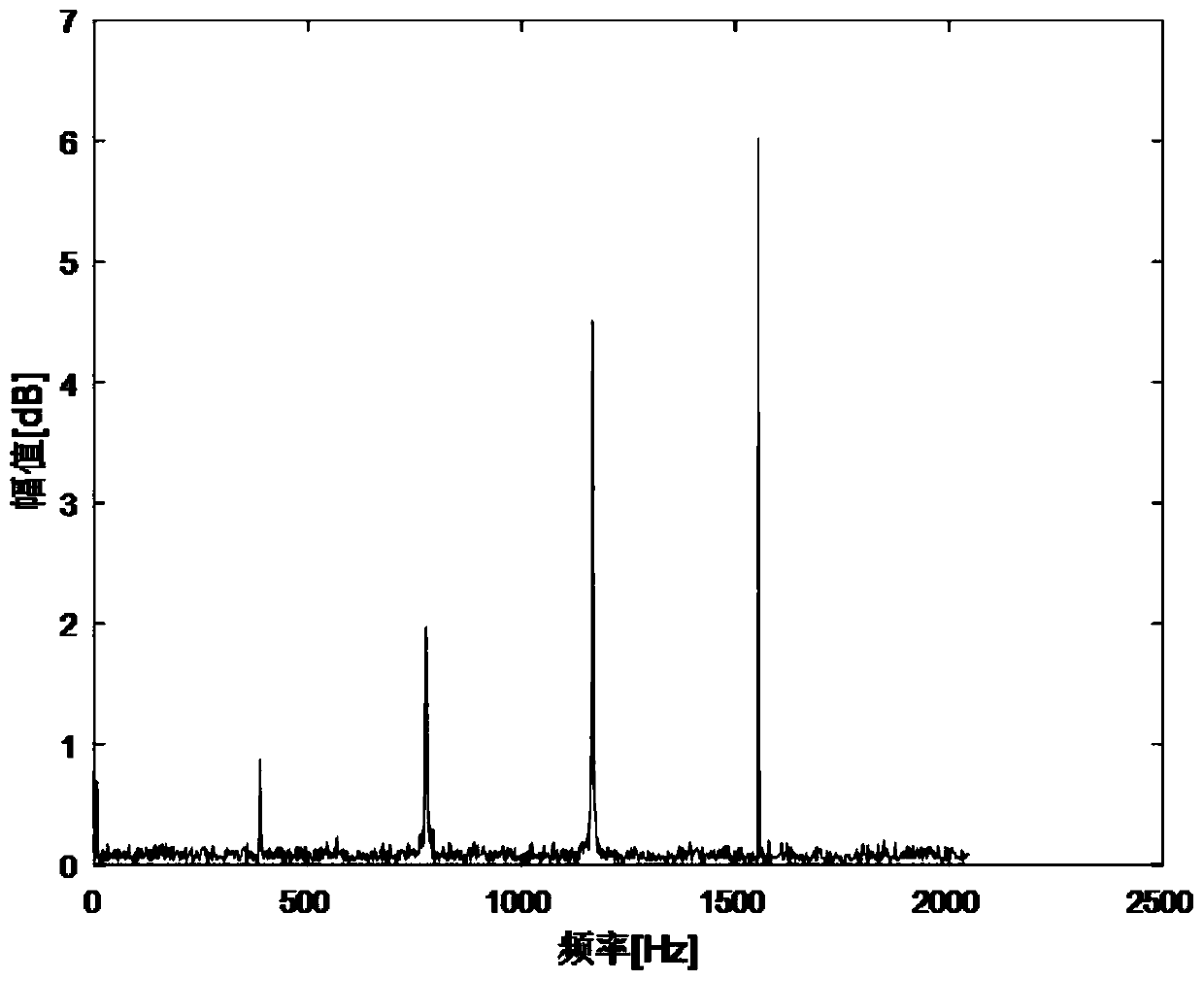

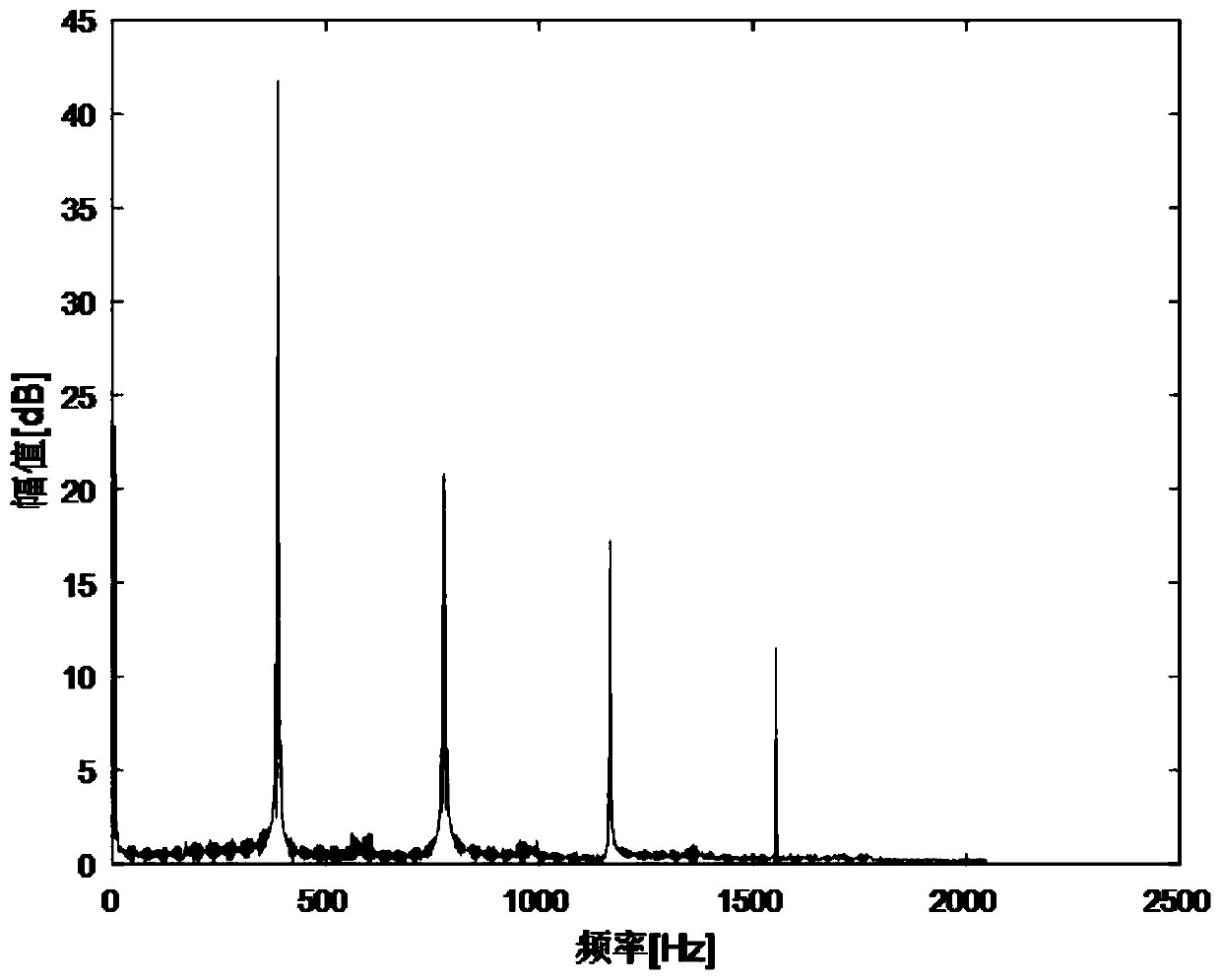

[0081] Using the gear parameters of the HXD1C transmission system as the basis, according to the different speeds of the pinion gears of the HXD1C locomotive, the speed of the locomotive is 120km / h, that is, the speed of the pinion gear is 342.79rad / s for signal simulation, the sampling frequency is 4096, and the number of sampling points The setting is 2048, and the number of teeth of the pinion is selected as 17. The specific gear parameters are shown in Table 1. Vibration signals corresponding to gear faults at a constant speed are established through Matlab. The simulated gear vibration signal types include gear normal operation, gear wear, gear broken teeth, and gear pitting, four common fault types.

[0082] Table 1 Gear parameters of HXD1C transmission system

[0083] gear modulus Number of teeth Tooth angle Addendum height factor full tooth height Radial variation coefficient big gear 9 106 20° 1.125 23.6248 -0.4085 gear 9 17 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com