Flush packaged pressure sensor with high temperature resistance and high frequency response

A pressure sensor and high temperature resistant technology, which is applied in the direction of measuring fluid pressure by changing ohmic resistance, measuring fluid pressure, and measuring the property and force of piezoresistive materials, which can solve the problems of easy leakage, failure, and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

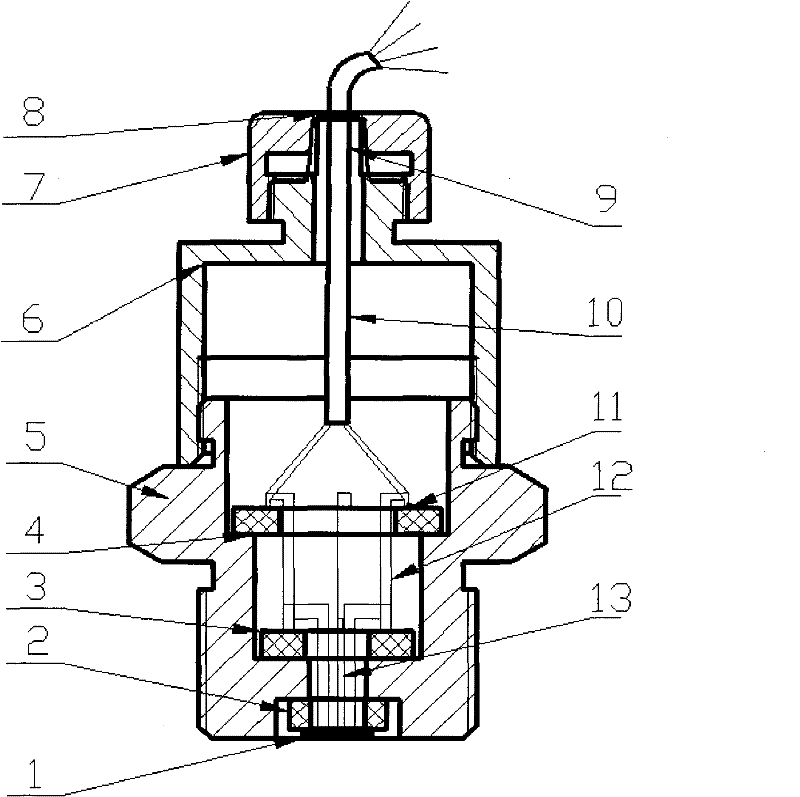

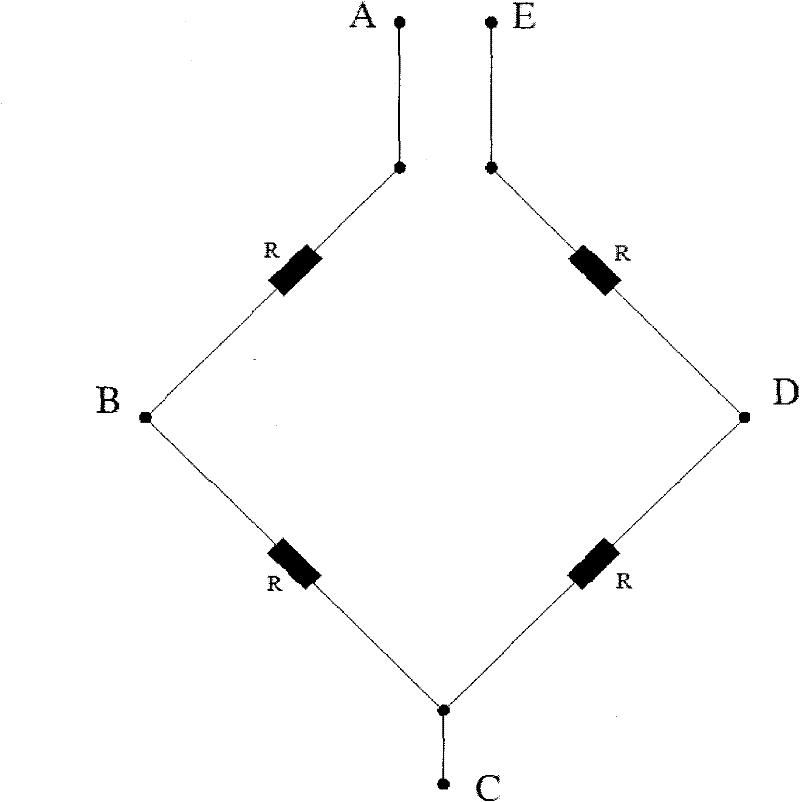

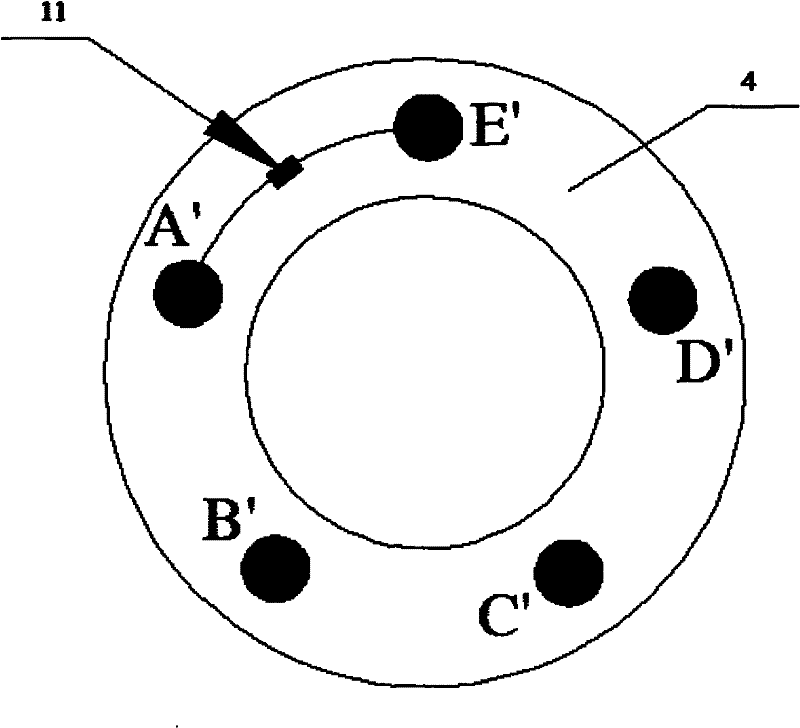

[0019] Refer to attached figure 1 , a flush-packaged high-temperature-resistant high-response pressure sensor, including a pressure chip 1, the pressure chip 1 is combined with the bottom surface of the glass ring 2 through electrostatic bonding, and the top of the glass ring 2 is connected with the bottom hole of the metal base 5 The upper part of the metal base 5 is bonded, the interior of the metal base 5 is a cavity, and two platforms are arranged in the middle and lower parts of the cavity. The high-temperature transfer board 3 and the high-temperature transfer circuit compensation board 4 are respectively fixed on the lower and middle platforms. The chip 1 is connected to the high-temperature transfer circuit board 3 through five gold wire leads 13, the high-temperature transfer board 3 is connected to the high-temperature transfer circuit compensation board 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com