Spline direct-connected planetary conical disc type stepless reducer

A speed changer and spline technology, applied in mechanical equipment, friction transmission devices, belts/chains/gears, etc., can solve the problems of coaxiality error, damage, verticality error, etc., and achieve low manufacturing and assembly accuracy requirements, Strong bearing capacity and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

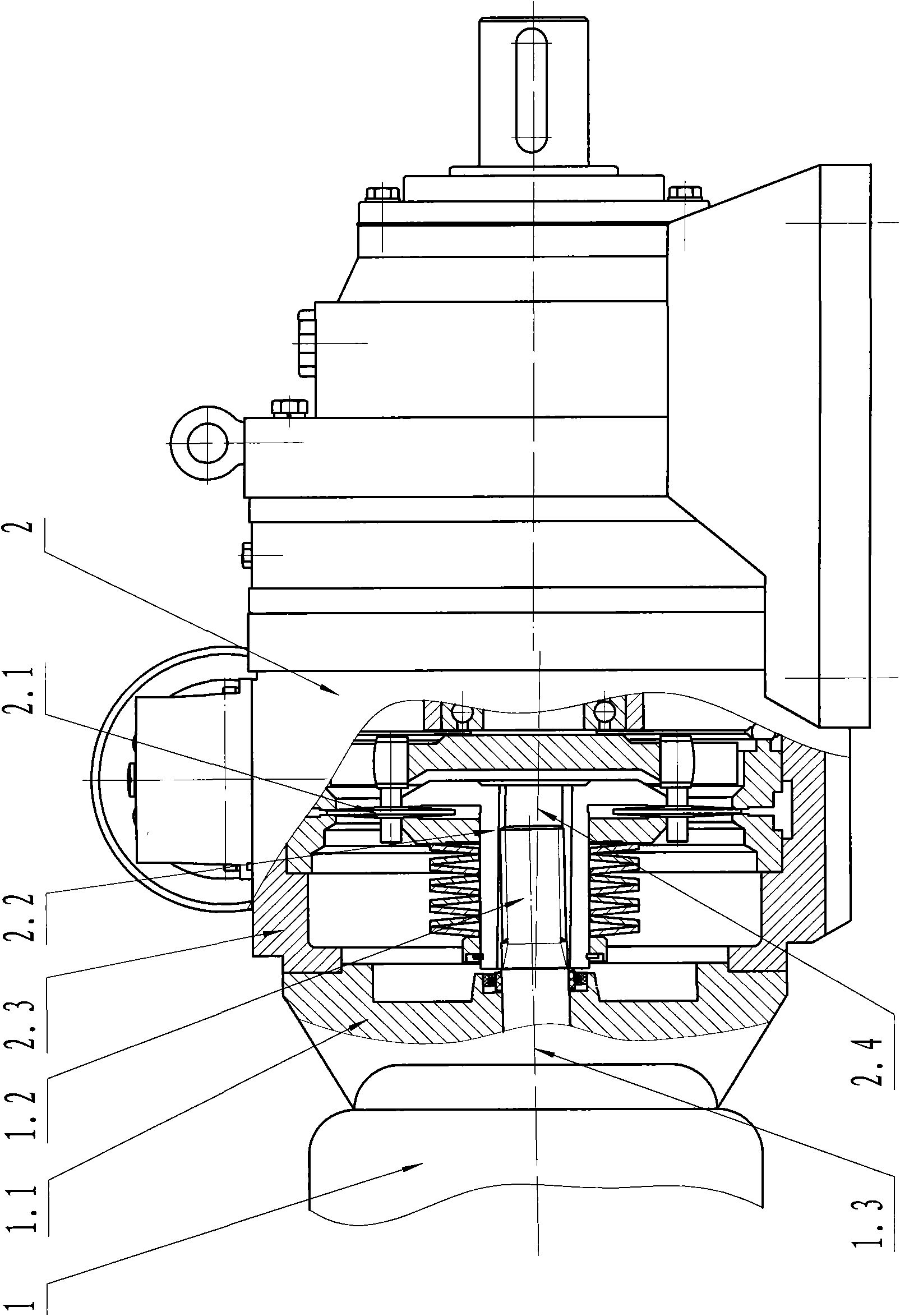

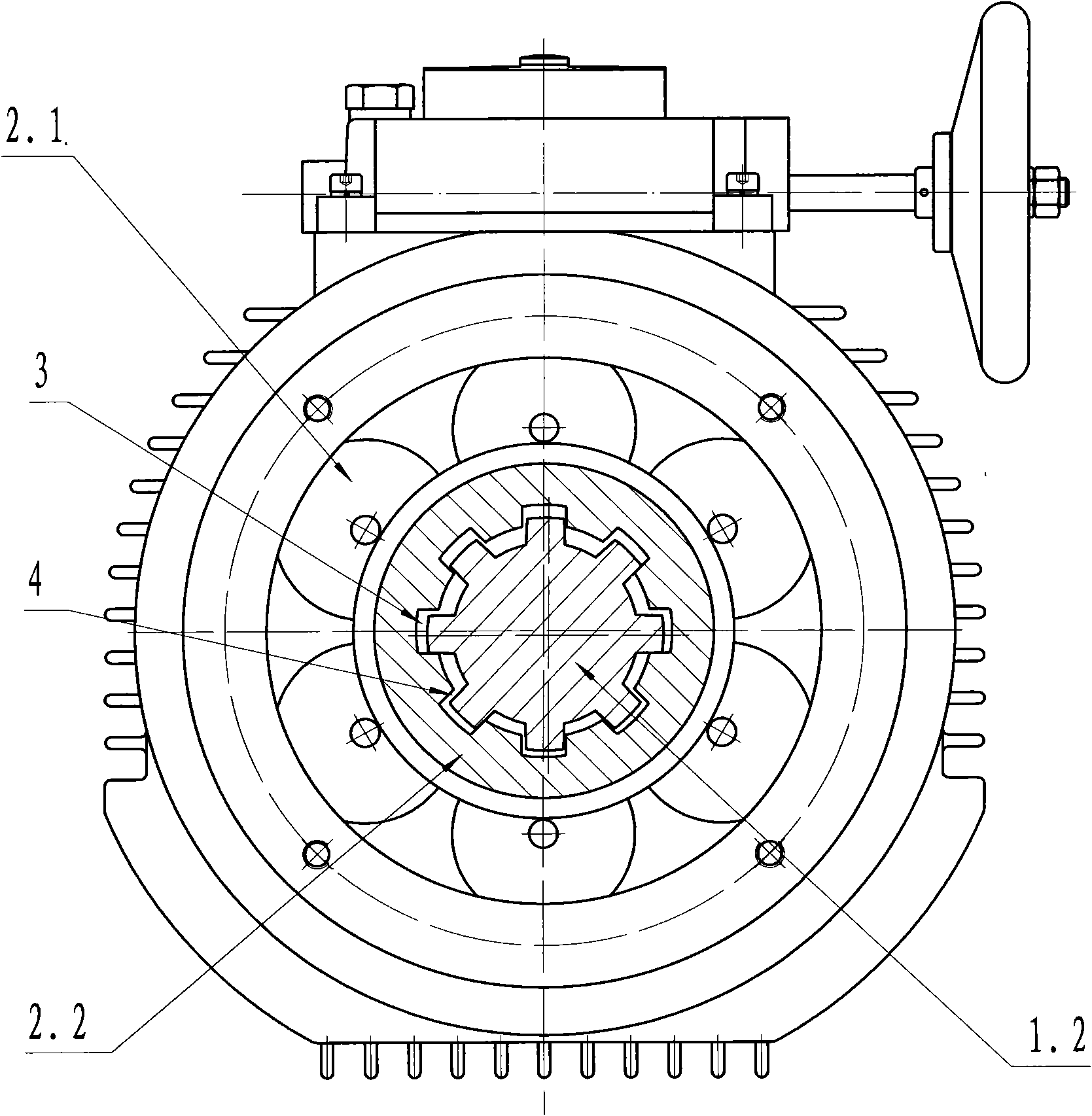

[0012] Such as figure 1 , figure 2 , the motor 1 and the direct-connected planetary cone-disc type continuously variable speed changer 2 are connected and fixed through the connecting flange 1.1 and the connecting flange 2.3, the output shaft 1.2 of the motor 1 is an external spline type, directly connected to the planetary cone-disk type continuously variable speed changer The driving wheel 2.2 of the machine 2 is an internal spline type, and the driving wheel 2.2 is supported and centered by the planetary cone disc 2.1, and the motor 1 is spline connected with the driving wheel 2.2 of the directly connected planetary cone disc type continuously variable speed changer 2 through the output shaft 1.2 , the number of spline teeth is 6, and the spline connection adopts large clearance fit, that is, there is a large radial clearance and side clearance between the output shaft 1.2 of the motor and the driving wheel 2.2 of the speed changer, the radial clearance is 0.25mm~1mm, and ...

Embodiment 2

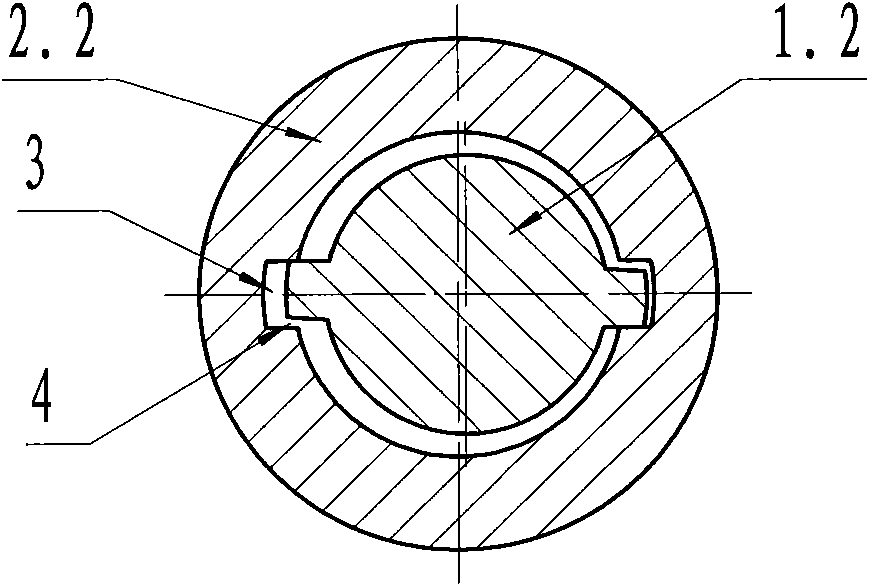

[0014] Such as figure 1 , image 3 , The motor 1 is spline-connected with the driving wheel 2.2 of the direct-connected planetary cone-disc type continuously variable transmission 2 through the output shaft 1.2, and the number of spline teeth is 2. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com