High-hydrophilic and exothermal spinning solution for polyacrylonitrile-based carbon fibers and preparation method thereof

A technology of polyacrylonitrile-based carbon fiber and spinning solution, which is applied to the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of reducing the performance of carbon fiber, not improving the exothermic performance of polyacrylonitrile alone, and hindering the degree of graphitization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

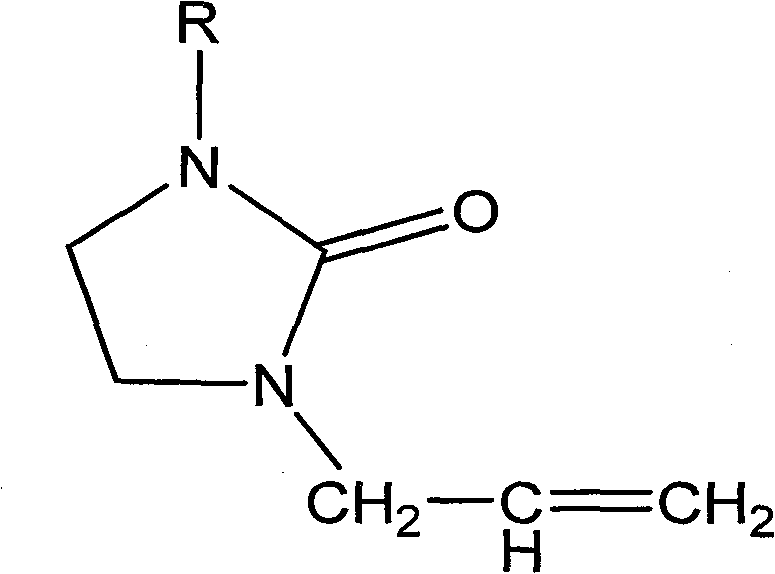

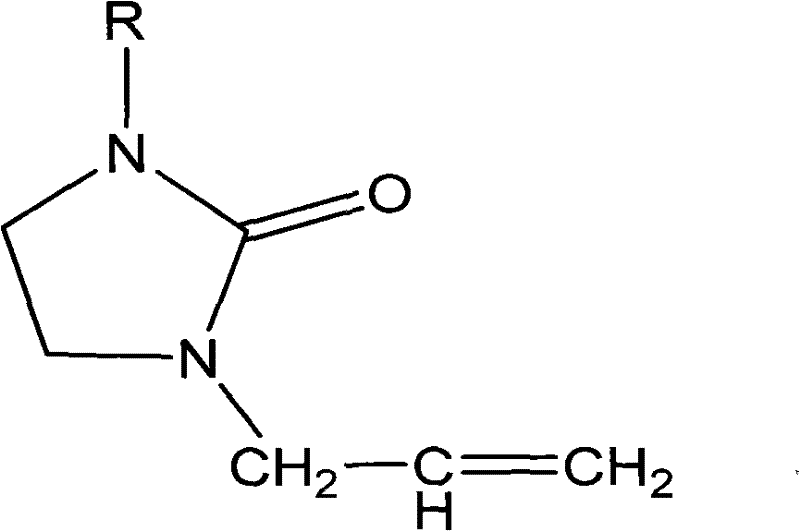

[0022] Example 1: Add initiator azobisisobutyronitrile, main monomer acrylonitrile, comonomer 1-allyl-2-imidazolidinone, solvent N, N-dimethylformamide to the condenser And mechanical stirring device in the reactor. The mass percentage ratio of the added raw materials is as follows: the main monomer acrylonitrile is 98% of the total monomer mass, and the comonomer 1-allyl-2-imidazolidinone is 2% of the total monomer mass. The mass of azobisisobutyronitrile is 0.5% of the total mass of the monomer, and the concentration of the total mass percentage of the monomer is 20%. Stir and mix at room temperature. After bubbling with nitrogen for 10-40 minutes, react at a constant temperature of 50°C for 24 hours under nitrogen protection, and then remove residual monomers and bubbles to obtain a spinning solution with high hydrophilicity and excellent exothermic properties. The mass concentration of the obtained spinning solution copolymer is 20%. The weight average molecular weight of...

Embodiment 2

[0023] Example 2: Add the initiator azobisisobutyronitrile, the main monomer acrylonitrile, the comonomer 1-allyl-2-imidazolidinone, the solvent N,N-dimethylformamide to the condenser And mechanical stirring device in the reactor. The mass percentage ratio of the added raw materials is the main monomer acrylonitrile which is 97% of the total monomer mass, and the comonomer 1-allyl-2-imidazolidinone is 3% of the total monomer mass. The mass of azobisisobutyronitrile is 0.5% of the total monomer mass, and the monomer mass concentration is 15%. Stir and mix at room temperature. After bubbling with nitrogen for 10-40 minutes, react at a constant temperature of 60°C for 6 hours under the protection of nitrogen, and then remove residual monomers and bubbles to obtain a spinning solution with high hydrophilicity and excellent exothermic properties. The mass concentration of the obtained spinning solution copolymer was 15%. The weight average molecular weight of the copolymer was 196...

Embodiment 3

[0024] Example 3: Add initiator azobisisobutyronitrile, main monomer acrylonitrile, comonomer 1-allyl-2-imidazolidinone, solvent N, N-dimethylformamide to the condenser And mechanical stirring device in the reactor. The mass percentage ratio of the added raw materials is: the main monomer acrylonitrile is 96% of the total monomer mass, and the comonomer 1-allyl-2-imidazolidinone is 4% of the total monomer mass. The mass of azobisisobutyronitrile is 0.5% of the total monomer mass, and the monomer mass concentration is 20%. Stir and mix at room temperature. After bubbling with nitrogen for 10-40 minutes, react at a constant temperature of 70°C for 24 hours under nitrogen protection, and then remove residual monomers and bubbles to obtain a spinning solution with high hydrophilicity and excellent exothermic properties. The obtained spinning solution copolymer has a mass concentration of 25%. The weight average molecular weight of the copolymer was 193,000. The contact angle of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com