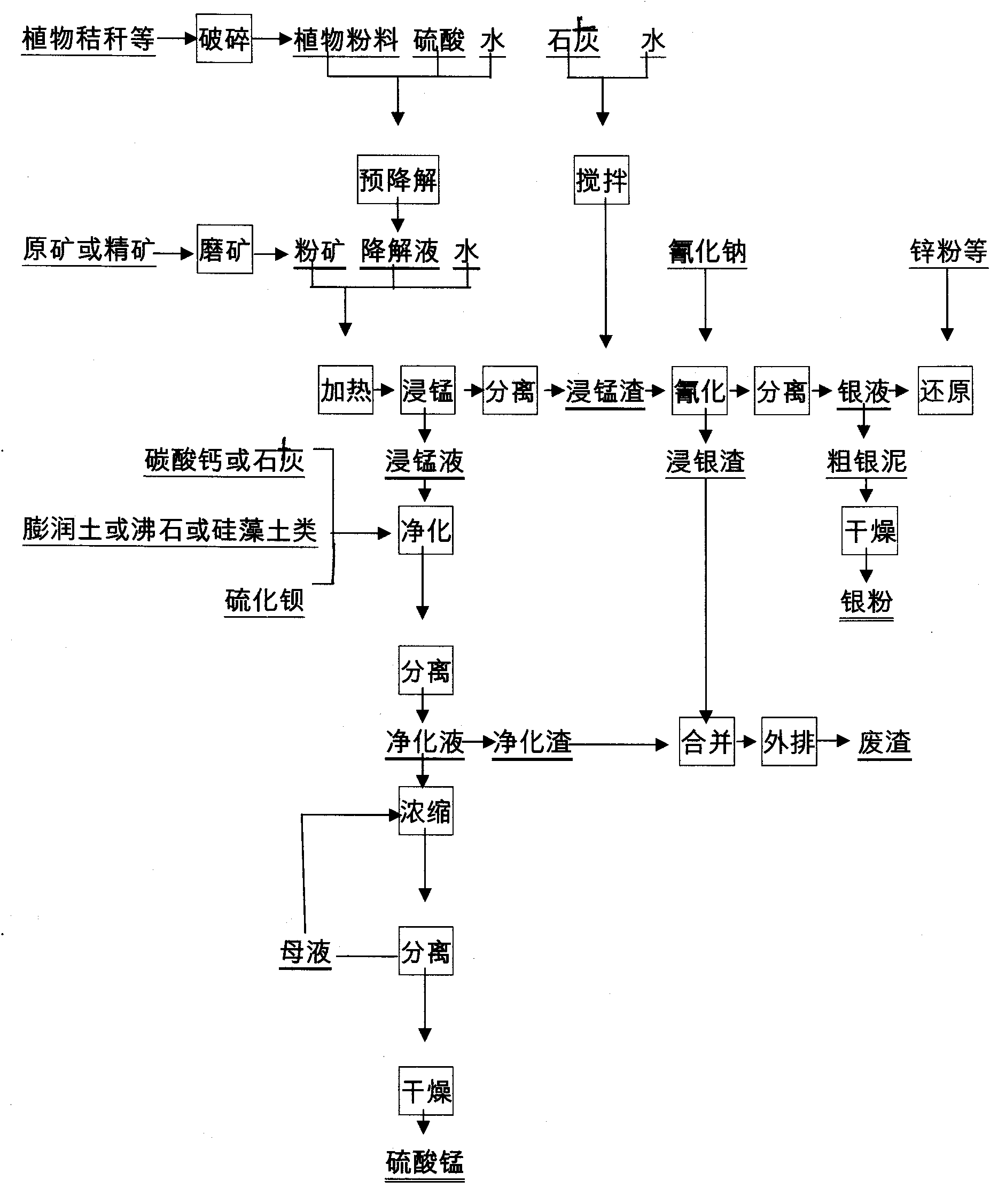

Method for separating manganese and silver of manganese-silver ore and extracting manganese sulfate by purifying manganese dipped solution

A technology of manganese silver ore and manganese sulfate, which is applied in the separation of manganese and silver ore and the purification of manganese leaching solution to extract manganese sulfate, silver separation and purification treatment of manganese leaching solution. It can solve the problem of reducing manganese in the field of manganese oxide ore containing silver. Low efficiency, large dust, high coal consumption and other problems, to achieve high separation and recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

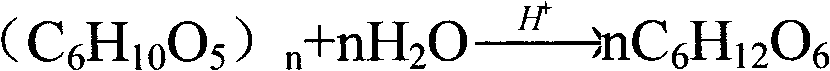

[0032] (1) Pre-crushed corn stalks to a powder with a particle size of about 0.15 mm, and added 1 kg of powder to W(H2 SO 4 ) = 95% of 3kg sulfuric acid, 5.3kg of water pre-mixed solution, stirring, heating to 95 ℃ pre-degradation saccharification 0.5h, adding content W (Mn) = 30.5%, silver 640g / t, W (Fe) = 11.5 4kg of manganese silver concentrate powder with a particle size of -0.075mm and 90%, 5kg of water, stirring and heat preservation at 90°C to 95°C for manganese leaching reaction for 5h, separating undissolved manganese leaching slag, washing manganese leaching slag with 12kg of water, manganese The leaching rate is 92.5%, and the silver leaching rate is less than 2%;

[0033] (2) Combine the manganese leaching solution and the washing solution, add 0.85kg of calcium carbonate, stir and heat up to 90°C and keep it warm for 1h. After neutralization, the pH of the solution is 5. Add 0.2kg of bentonite and keep it warm for 0.5h. Iron slag removal;

[0034] (3) Purificati...

Embodiment 2

[0039] (1) Wheat bran is pre-crushed to a powder with a particle size of about 0.15 mm, and 0.8 kg of powder is added to W(H 2 SO 4 ) = 95% of 3kg sulfuric acid, 5.3kg of water pre-mixed solution, stirring, heating to 60 ° C pre-degradation saccharification 1h, add content W (Mn) = 30.5%, silver 640g / t, W (Fe) = 11.5% 4kg of manganese-silver concentrate powder with a particle size of -0.075mm and 90%, add 5kg of water, stir and raise the temperature at 90°C to 95°C to leach manganese for 4 hours, separate the undissolved manganese leaching slag, wash the manganese leaching slag with 12kg of water, and the manganese leaching rate 93.10%, silver dissolution rate is less than 2%;

[0040] (2) Combine the manganese leaching solution and the washing solution, add 0.85kg of calcium carbonate, stir and heat up to 90°C, the pH value of the solution after neutralization is 5, add 0.1kg of natural zeolite powder and keep it warm for 0.5h, separate Iron slag removal;

[0041] (3) Puri...

Embodiment 3

[0046] (1) The fibrous slag of apple juice is pre-crushed to a powder with a particle size of about 0.50 mm, and 0.5 kg of powder is added to W(H 2 SO 4 ) = 95% of 3kg sulfuric acid, 5.3kg of water pre-mixed solution, stirring, heating to 95 ℃ pre-degradation saccharification 0.5h, adding content W (Mn) = 30.5%, silver 640g / t, W (Fe) = 11.5 4kg of manganese-silver concentrate powder with a particle size of -0.075mm and 90%, add water 9kg, stir and raise the temperature at 90°C to 95°C to leach manganese for 3 hours, separate the undissolved manganese leaching slag, wash the manganese leaching slag with 12kg of water, and manganese leaching The rate is 93.50%, and the silver dissolution rate is less than 2%;

[0047] (2) Combine the manganese leaching liquid and the washing liquid, add 0.70 kg of calcium carbonate, stir and heat up to 90 ° C, the pH value of the solution after neutralization is 5, add 0.3 kg of diatomaceous earth powder for 0.5 h, separate Remove iron slag; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com