Method for improving quality of concentrated natural latex

A natural latex quality technology, applied in the field of quality control of concentrated natural latex, can solve the problems of latex products such as the decline in anti-oxidative aging performance, and achieve the effect of improving anti-oxidative aging performance and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

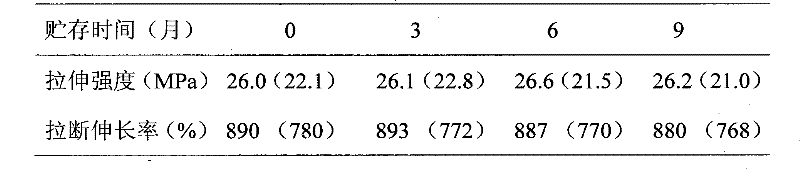

[0017] Take by weighing 250 parts of dry glue content and be the fresh natural rubber latex that the ammoniacal liquor of 40% preserves, add 2.0 parts of 5% diammonium hydrogen phosphate aqueous solution, 1 part of 5% ammonium ethylenediamine tetraacetate aqueous solution, mix well, and stand at room temperature for 1 Hours later, the centrifugal concentration can be carried out according to the conventional production process. The concentrated natural rubber latex of gained is stored naturally, is sampled every 3 months, vulcanizes and forms a film according to a conventional process, wherein 1.0 part of sulfur consumption, 1.0 part of zinc diethyldithiocarbamate consumption, 0.5 part of zinc oxide consumption, The vulcanization condition is 60° C.×60 minutes. After standing at room temperature for 24 hours, add 1.0 parts of 2,2'-methylenebis(4-methyl-6-tert-butylphenol), and the mechanical properties of the obtained film after aging at 70°C for 72 hours are as follows:

[0...

Embodiment 2

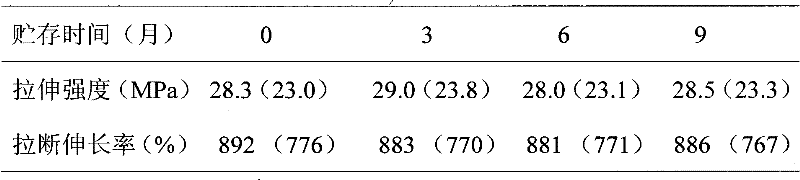

[0022] Take by weighing 333 parts of dry rubber content and be the fresh natural rubber latex that the ammoniacal liquor of 30% preserves, add 3 parts of 5% diammonium hydrogen phosphate aqueous solution, 1 part of 5% ammonium ethylenediamine tetraacetate aqueous solution, mix well, and stand at room temperature for 1 Hours later, the centrifugal concentration can be carried out according to the conventional production process. The concentrated latex of gained is stored naturally, is sampled every 3 months, vulcanizes and forms a film according to a conventional process, wherein the sulfur consumption is 1.0 part, the zinc diethyldithiocarbamate consumption 1.0 part, the zinc oxide consumption 0.5 part, vulcanization The conditions are 60°C x 60 minutes. After standing at room temperature for 24 hours, add 1.0 parts of 2,6-di-tert-butyl-4-methylphenol, and the mechanical properties of the obtained film after aging at 70°C for 72 hours are as follows:

[0023] Table 2 Mechanic...

Embodiment 3

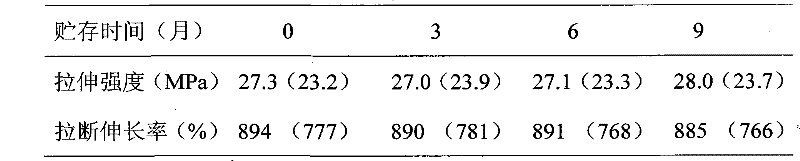

[0027] Take by weighing 400 parts of dry glue content and be the fresh natural rubber latex that the ammoniacal liquor of 25% preserves, add 2 parts of 5% diammonium hydrogen phosphate aqueous solution, 1 part of 5% ammonium ethylenediamine tetraacetate aqueous solution, after mixing evenly, leave standstill at room temperature for 1 Hours later, the centrifugal concentration can be carried out according to the conventional production process. Store the treated concentrated latex naturally, take samples every 3 months, vulcanize and form a film according to the conventional process, wherein the dosage of sulfur is 1.0 parts, the dosage of zinc diethyldithiocarbamate is 1.0 parts, and the dosage of zinc oxide is 0.5 parts , The vulcanization condition is 60°C×60 minutes. After standing at room temperature for 24 hours, add 1.0 parts of 4,4'-methylenebis(2,6-di-tert-butylphenol), and the mechanical properties of the obtained film after aging at 70°C for 72 hours are as follows: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com