Method for treating 2,4,6-trinitrotoluene waste water and application thereof

A trinitrotoluene and waste water technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Unstable effect and other problems, to achieve the effect of stable treatment effect, avoid inhibition or side effects, and short domestication period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

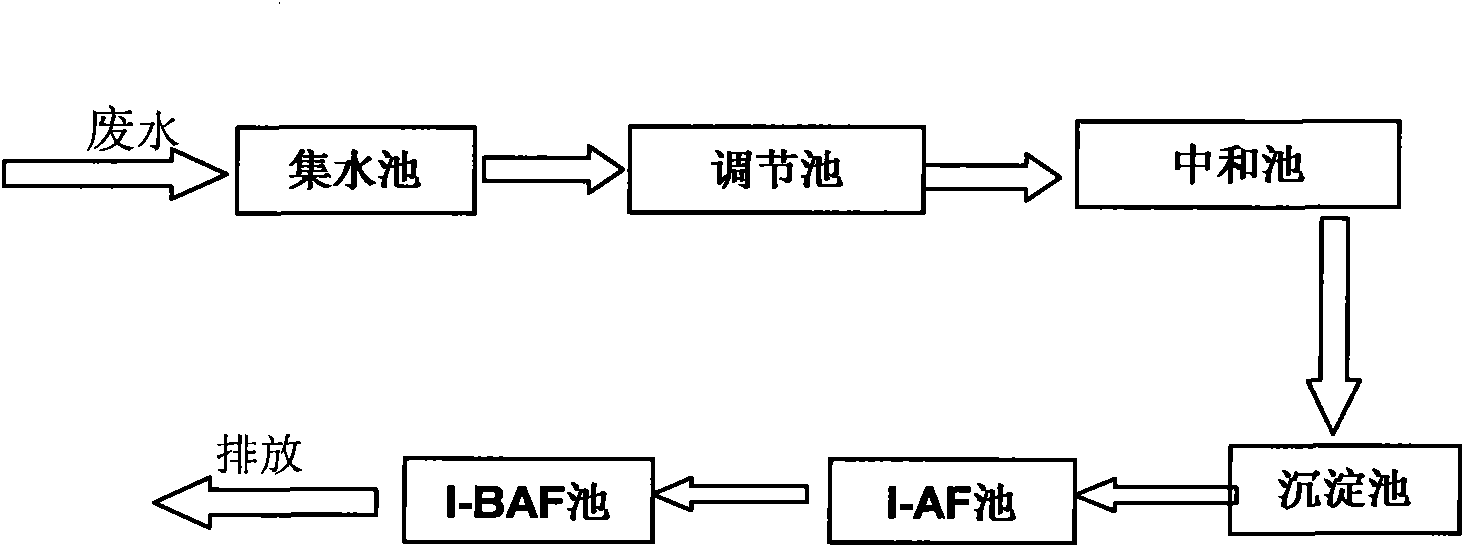

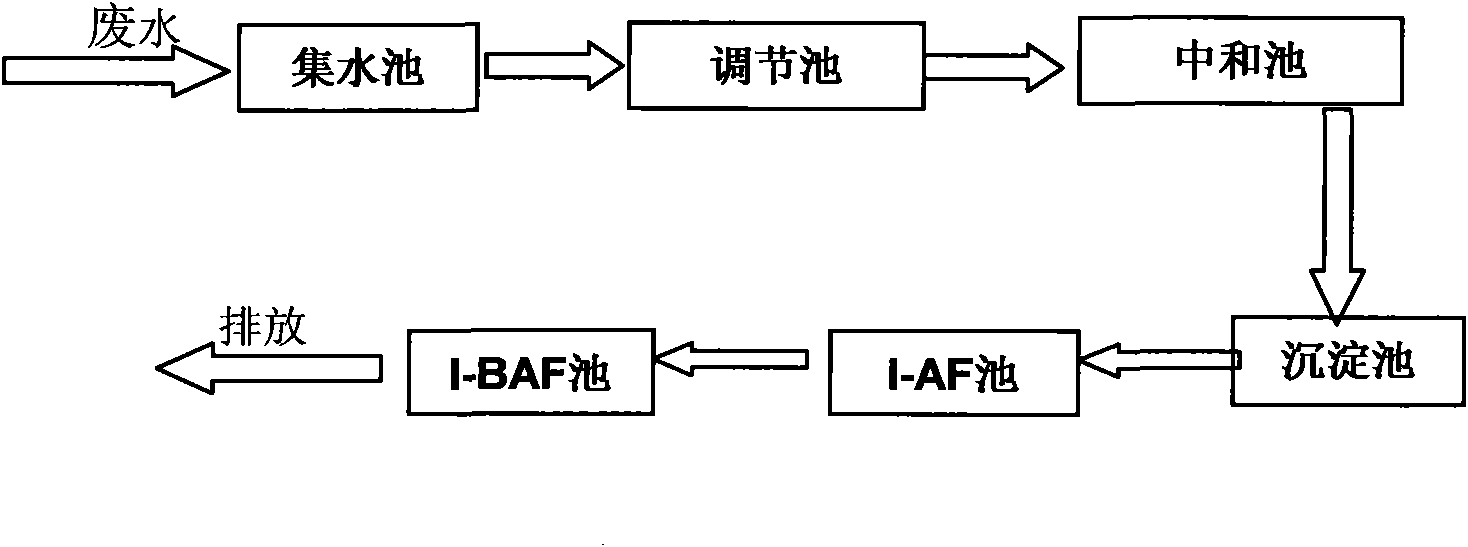

Method used

Image

Examples

Embodiment 1

[0025] Adopt the present invention to treat the TNT depressurized water of an explosive factory, the COD concentration of raw water is 300mg / L, the concentration of TNT+DNT (dinitrotoluene)+MNT (-nitrotoluene) is 100mg / L, and the treatment capacity is 6000m 3 / d, the water temperature in I-AF and I-BAF is controlled at 20°C-40°C, the hydraulic retention time is 12h and 16h respectively, the concentration of COD in the effluent is 60mg / L, the concentration of nitrobenzene is 2mg / L, and the concentration of aniline It is 1mg / L.

Embodiment 2

[0027] The present invention is used to treat TNT refined waste water of an explosives factory. After the raw water is pretreated, the COD concentration is 800mg / L, the TNT+DNT+MNT concentration is 150mg / L, and the treatment capacity is 380m 3 / d, the water temperature in I-AF and I-BAF is controlled at 20°C-40°C, the hydraulic retention time is 20h and 26h respectively, the final effluent COD concentration is 100mg / L, nitrobenzene concentration is 2mg / L, aniline concentration It is 1mg / L.

Embodiment 3

[0029] Using the present invention to treat nitrobenzene and aniline wastewater in a chemical plant, the COD concentration of the raw water after pretreatment is 1500mg / L, the nitrobenzene concentration is 250mg / L, the aniline concentration is 600mg / L, and the treatment capacity is 3600m 3 / d, the water temperature in I-AF and I-BAF is controlled at 20°C-40°C, the hydraulic retention time is 28h and 30h respectively, the concentration of COD in the effluent is 100mg / L, the concentration of nitrobenzene is 2mg / L, and the concentration of aniline is 1mg / L.

[0030] It can be seen from the above examples that the present invention has a good treatment effect on TNT wastewater of different water quality and similar wastewater.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com