Method for treating leather-making industrial wastewater

A technology for industrial wastewater and treatment methods, which is applied in animal processing wastewater treatment, biological water/sewage treatment, flotation water/sewage treatment, etc., and can solve problems such as low ammonia nitrogen removal rate, unsatisfactory removal effect, and water pollution. , to achieve the effect of improving the biochemical treatment effect, shortening the hydraulic retention time, and reducing the occupied area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

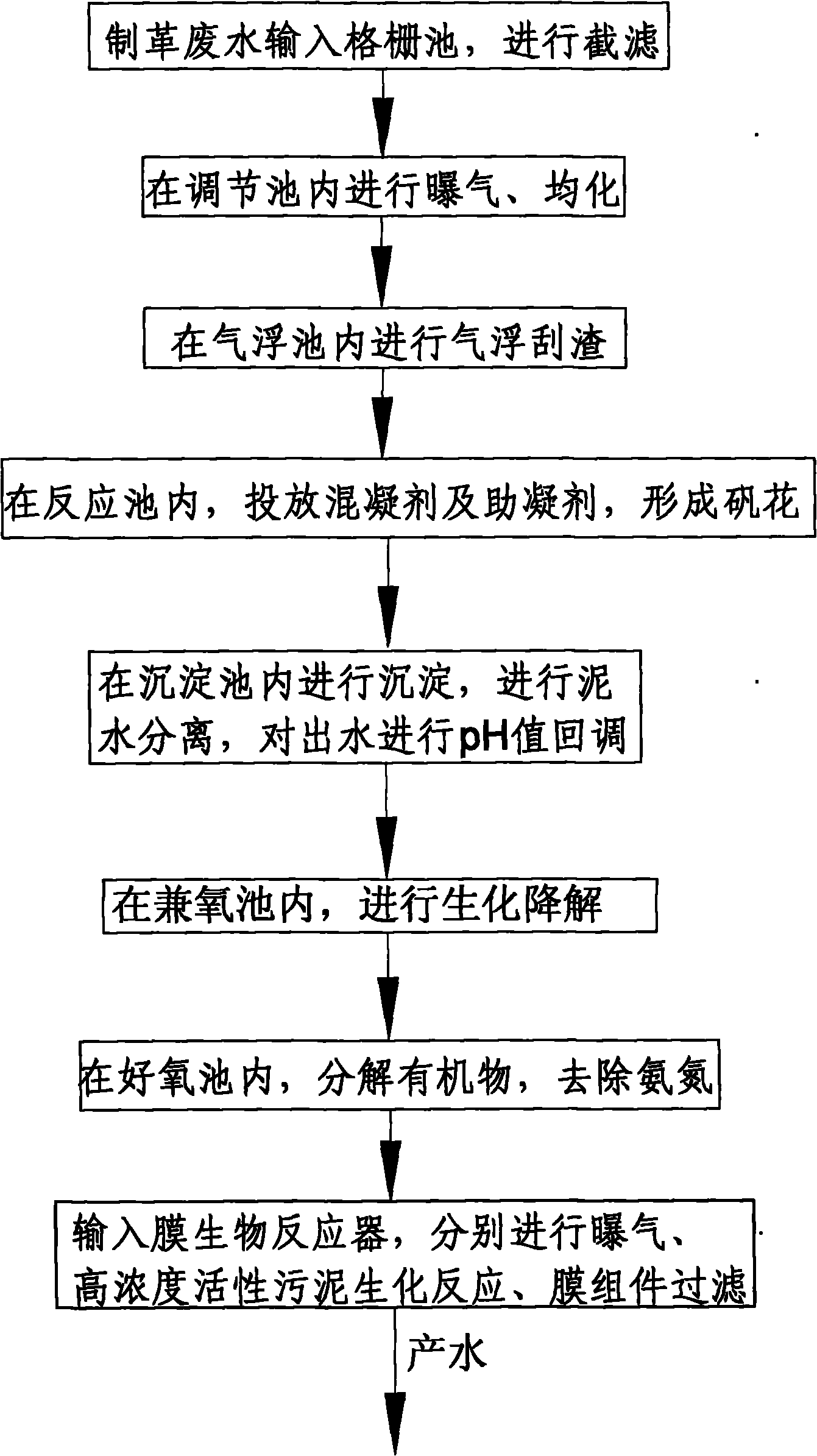

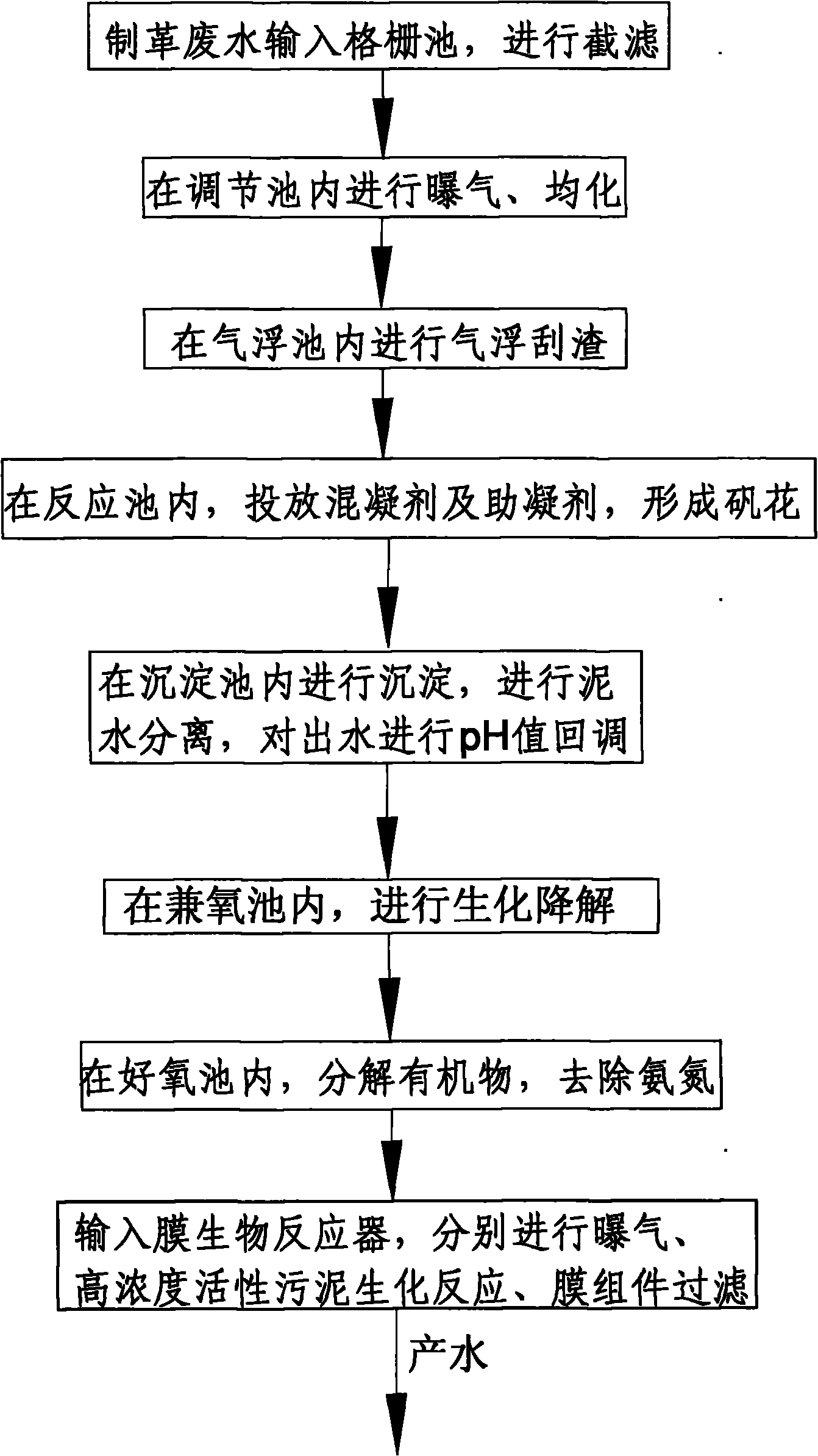

[0033] Reference attached figure 1 In the method for treating wastewater from the tanning industry of the present invention,

[0034] a. First, pump the tannery wastewater into the grid pool to intercept and filter the suspended solids in the wastewater; the purpose of the grid process is to effectively intercept and filter the hair and other sundries in the tanning wastewater to protect the subsequent treatment The equipment in the system is operating normally.

[0035] b. Inject the wastewater obtained in step a above into a regulating tank equipped with an aeration device to homogenize the wastewater in the tank; the purpose is to effectively adjust the water quality and quantity of wastewater from the tanning industry.

[0036] c. The waste water obtained in step b is injected into the air flotation tank, and the suspended solid particles and oily substances are removed after the air flotation and slag scraping. The reason is that these substances are present in large amounts in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com