Hoisting method of thin-wall long and thin large-size equipment

A large-scale equipment and hoisting method technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve problems such as many safety risks, high labor intensity, quality impact of equipment body and internal parts, etc., to achieve safe operation and smooth hoisting process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

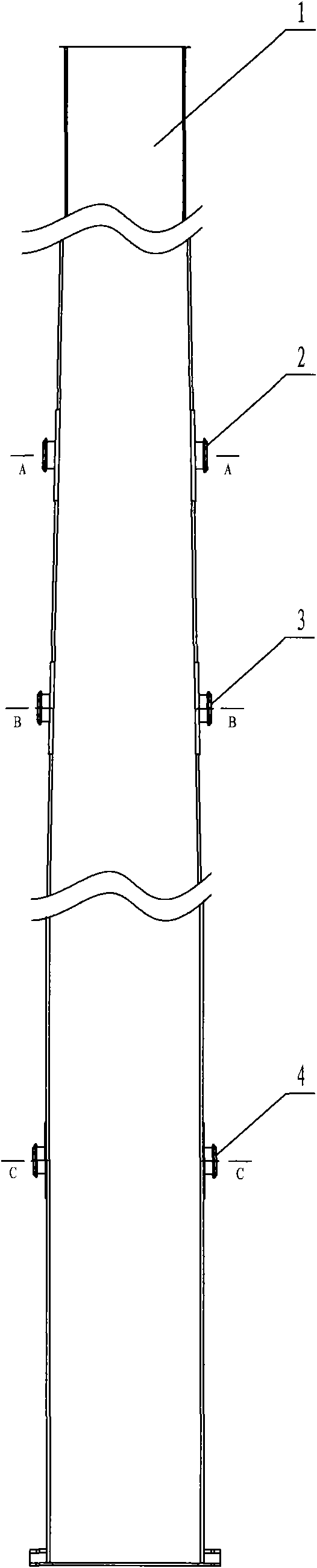

[0021] This method is used to hoist the 60m steel chimney as a whole, and the specific steps are as follows:

[0022] 1. If figure 1 Set two upper set of main lifting lugs I2 and two lower set of main lifting lugs II3 on thin-walled and slender large-scale equipment 1, the distance between the upper set of main lifting lugs I2 and the top of the equipment is 20m, and the distance between the lower set of main lifting lugs II3 and the upper set of main lifting lugs I2 is 5m, such as Figure 4 , Figure 5 The two sets of main lifting lugs are staggered by 0.39m along the center line; The tail-sliding lug 4 is 8m away from the bottom end. Such as Figure 4 Lug I2, such as Figure 5 A carbon steel pipe with a diameter of 530mm and a reinforcement plate 8 with a diameter of 1800mm are selected for the main lug II3.

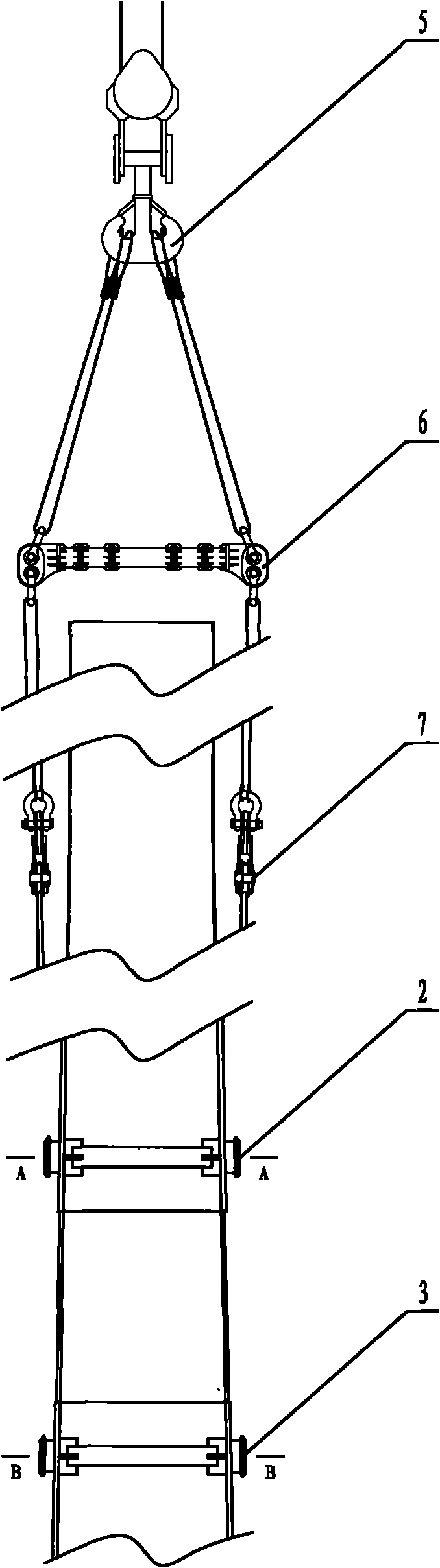

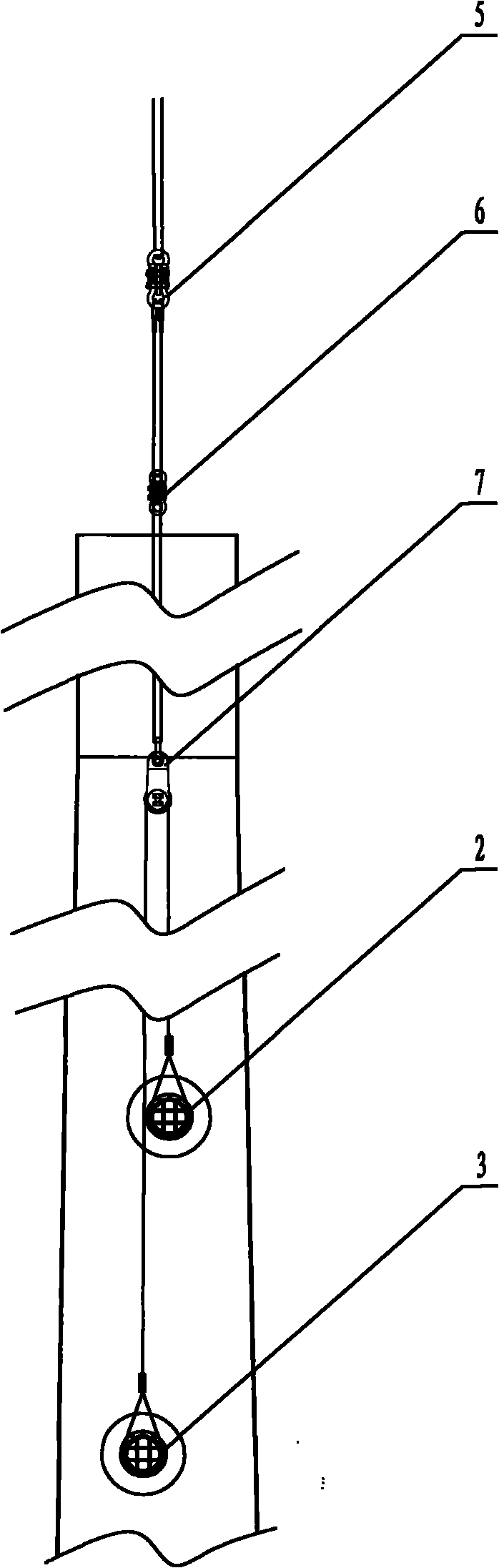

[0023] 2. If figure 2 , image 3 The main hook 5 is connected to the balance beam 6 through a steel wire rope, and the two ends of the balance beam 6 are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com