Jaw type vibration crusher

A crusher and jaw technology, applied in the field of jaw crushers, can solve the problems of large amount of fine and powder materials, equipment damage, and large amount of waste, so as to reduce the loss of raw materials, prevent damage to the machine body, and ensure the crushing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

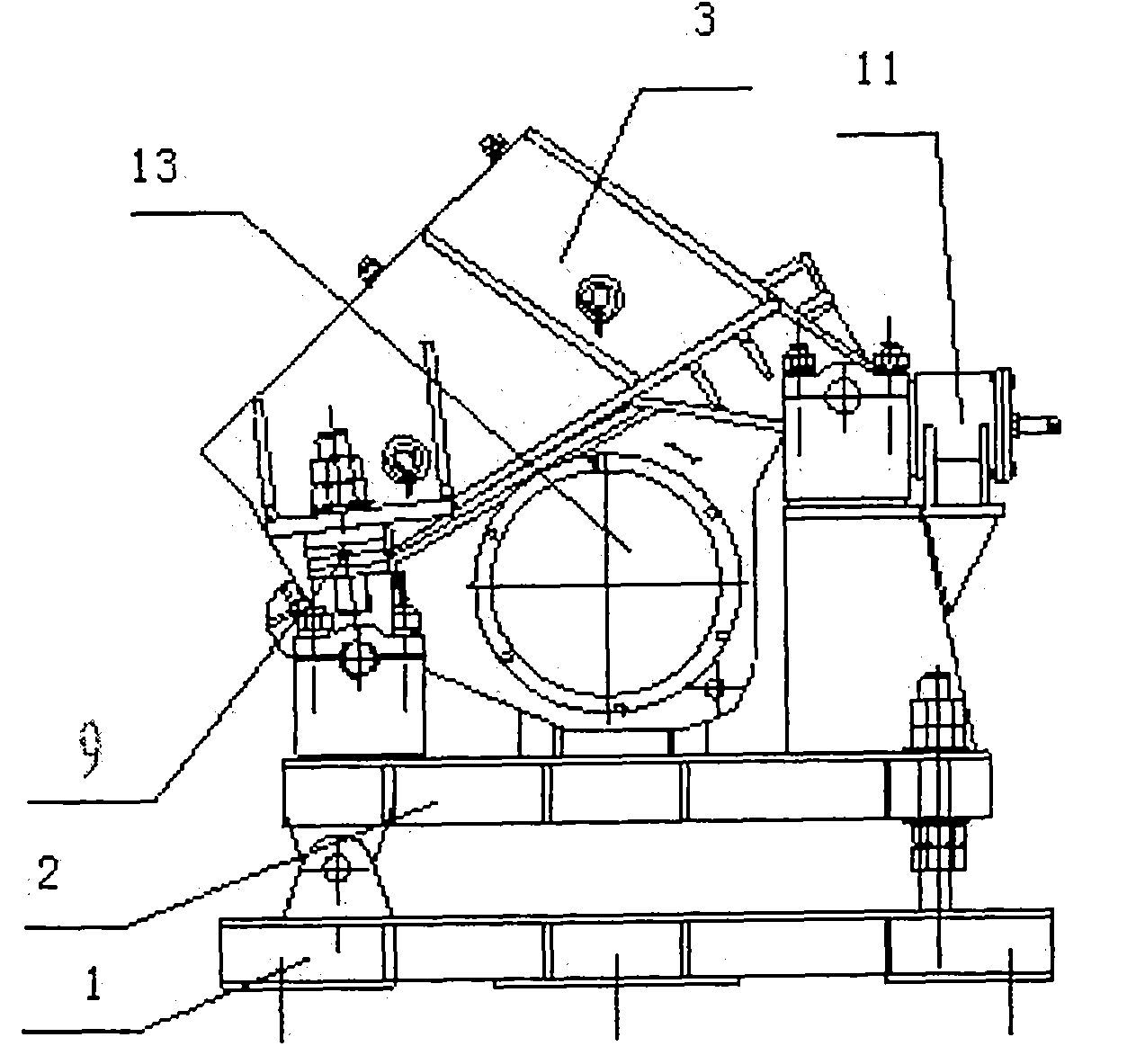

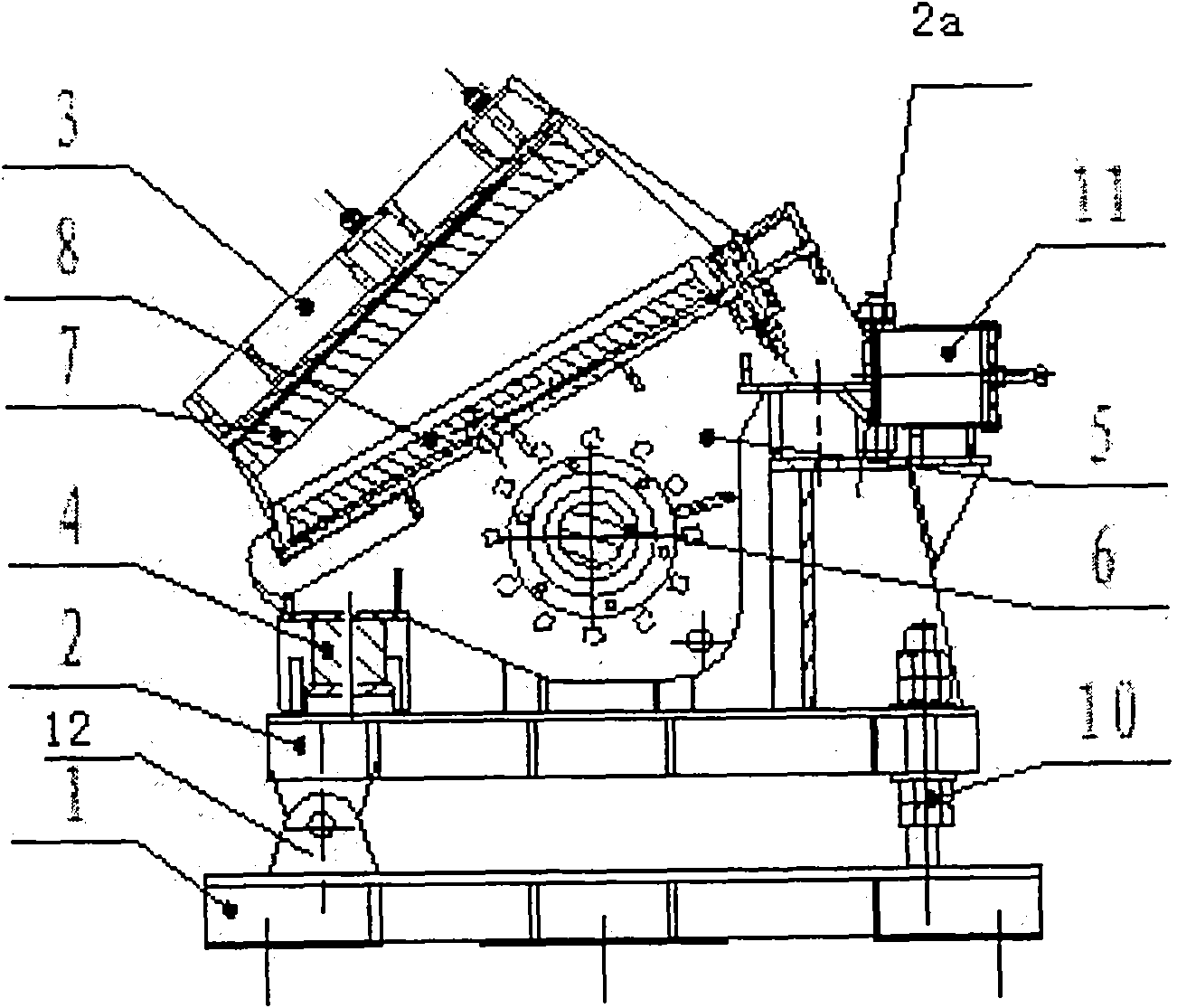

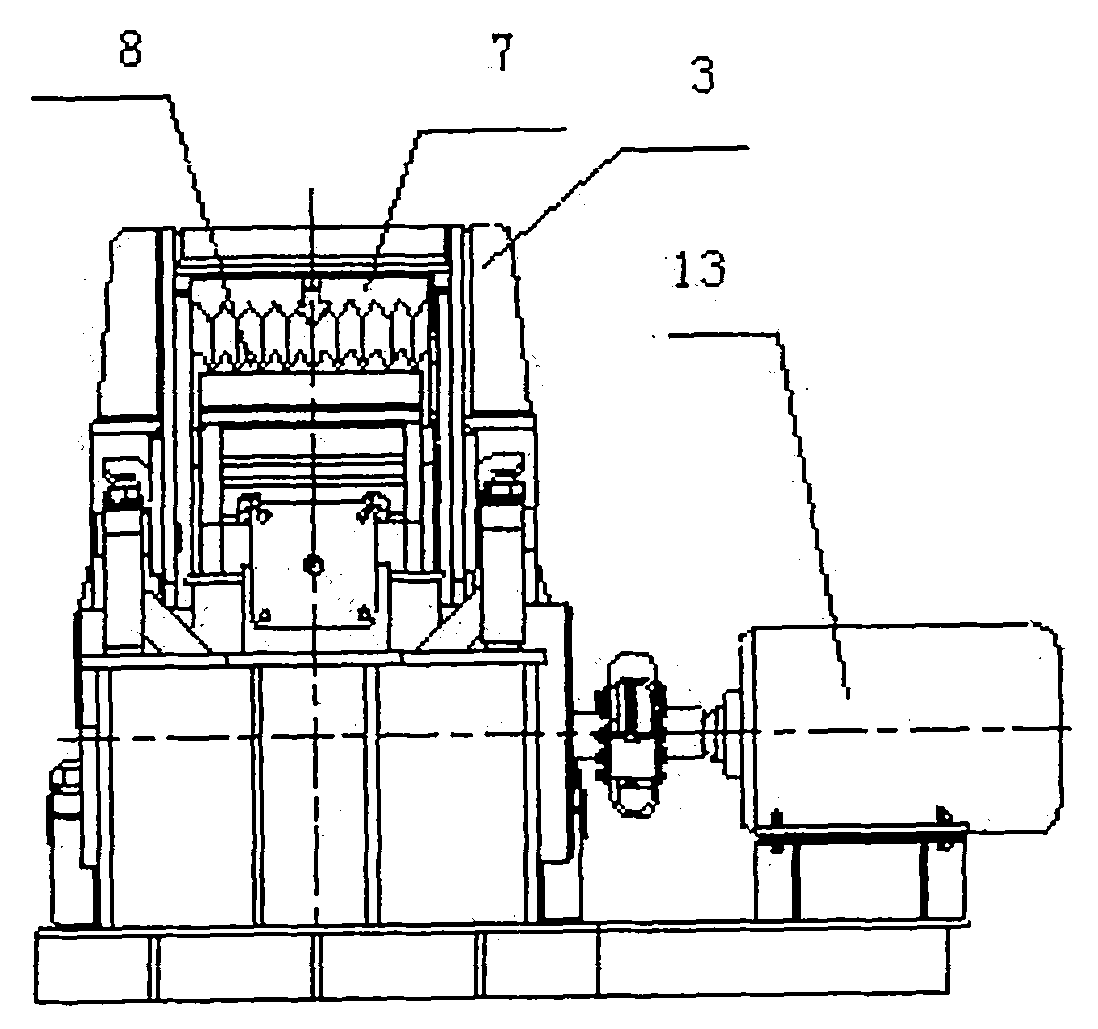

[0016] As shown in the figure, the present invention includes a chassis 1 installed on the foundation, a base 2 installed on the chassis 1 through a hinge 12 on one side and a screw mechanism 10 on the other side, and a fixed box 3 through a pin shaft and an adjustment device 9 is installed on the machine base 2. The adjustment device 9 in this embodiment also adopts a screw mechanism. By adjusting the screw, the upper and lower positions of the discharge port end of the fixed box can be adjusted to realize the adjustment of the size of the discharge port of the crushing chamber of the crusher. There are brackets 2a, 2b with different heights on both sides of the machine base 2, and the fixed box body 3 is installed on the brackets with different heights on both sides and then becomes inclined. The buffer spring device 4 is installed on the machine base 2 through a vertical bolt. The buffer spring device 4 is a rubber spring device arranged along the four corners of the base 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com