Soft foaming sponge for seats and preparation method of soft foaming sponge

A soft foaming and sponge technology is applied in the field of soft foaming sponge for seats and its preparation, which can solve the problems of insufficient smooth surface of sponge products, unstable pressure and temperature, poor sealing performance of sponge molds, etc., and achieve stable production conditions. Control, temperature and pressure stabilization, reduce the effect of honeycomb phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

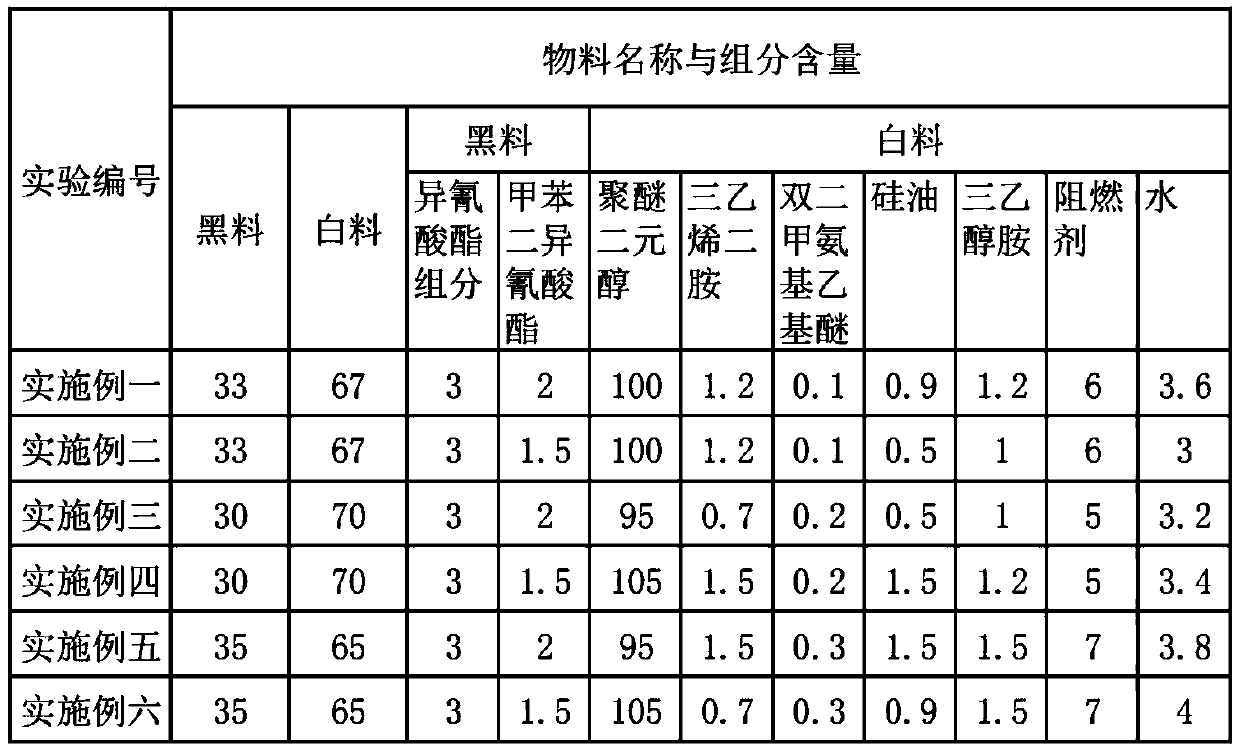

Examples

Embodiment 1

[0046] A kind of preparation method of soft foam sponge for seat, it is characterized in that: comprise the steps:

[0047] Step (1): Mix the isocyanate component and the toluene diisocyanate component according to the proportion, stir evenly, and obtain the black material;

[0048] Mix polyether diol, triethylenediamine solution, bisdimethylaminoethyl ether solution, silicone oil, triethanolamine, flame retardant, and water according to the ratio, and stir evenly to obtain a white material;

[0049] Step (2): Preheat the mold so that the mold is stable and constant at 50-55°C. Place the iron frame of the seat back as a whole in the mold in advance, and place both ends of the iron frame completely inside the mold, and place the inside of the mold The edges of both ends of the iron frame are sealed, and then the black material and white material are injected into the mold according to the ratio;

[0050] Step (3): After the black material and white material are injected into t...

Embodiment 2

[0065] The preparation method of the soft foam sponge in this embodiment is the same as the preparation method of the above-mentioned embodiment one.

[0066] A kind of soft foam sponge for seat, its raw material comprises black material and white material, and the weight part of black material is 33 parts, and the weight part of white material is 67 parts;

[0067] The black material comprises an isocyanate component and a toluene diisocyanate component, and the isocyanate component and the toluene diisocyanate component are arranged according to a weight ratio of 3:1.5;

[0068] The isocyanate component is formed by mixing isocyanate and diphenylmethane diisocyanate, and the viscosity of the isocyanate component is 200mPa·s at 25°C;

[0069] The toluene diisocyanate component is compounded from 2,4-toluene diisocyanate and 2,6-toluene diisocyanate, and the ratio of 2,4-toluene diisocyanate and 2,6-toluene diisocyanate is 4:1 by weight Scale setting;

[0070] White material...

Embodiment 3

[0079] The preparation method of the soft foam sponge in this embodiment is the same as the preparation method of the above-mentioned embodiment one.

[0080] A kind of soft foam sponge for seat, its raw material comprises black material and white material, and the weight part of black material is 30 parts, and the weight part of white material is 70 parts;

[0081] The black material comprises an isocyanate component and a toluene diisocyanate component, and the isocyanate component and the toluene diisocyanate component are set according to a weight ratio of 3:2;

[0082] The isocyanate component is formed by mixing isocyanate and diphenylmethane diisocyanate, and the viscosity of the isocyanate component is 200mPa·s at 25°C;

[0083] The toluene diisocyanate component is compounded from 2,4-toluene diisocyanate and 2,6-toluene diisocyanate, and the ratio of 2,4-toluene diisocyanate and 2,6-toluene diisocyanate is 4:1 by weight Scale setting;

[0084] White material is mad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com