Making process related to suit lapel

A production process and lapels technology, which is applied to the production process of suit lapels, which can solve the problems of not being able to turn the lapels in place, the size of the left and right lapels are inconsistent, and achieve the effect of consistent size and width.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0058] A manufacturing process related to suit lapels, the process includes the following steps:

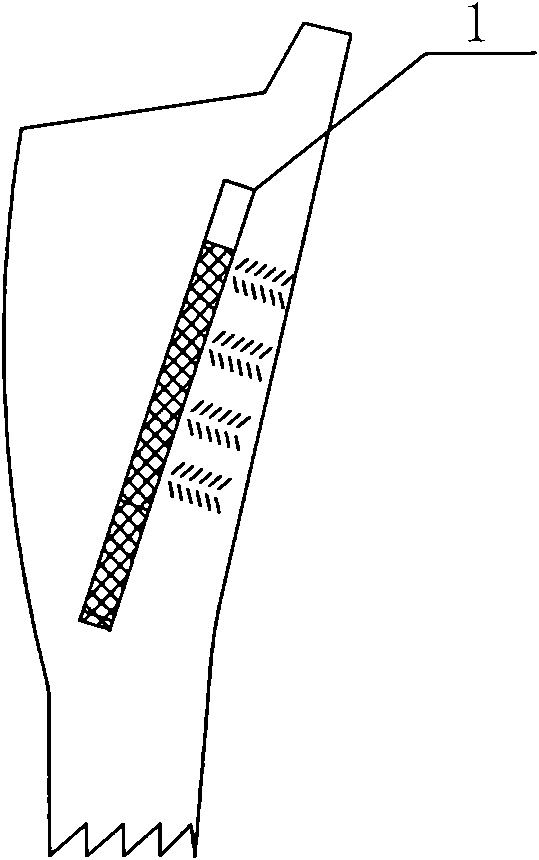

[0059] Step 1: When covering the chest lining 6, use a stapler to sew the chest lining 6 to the body; on the half auxiliary lining of the right lapel 2 folded line 10, use the leash 1 to close the folded amount of 0.5cm.

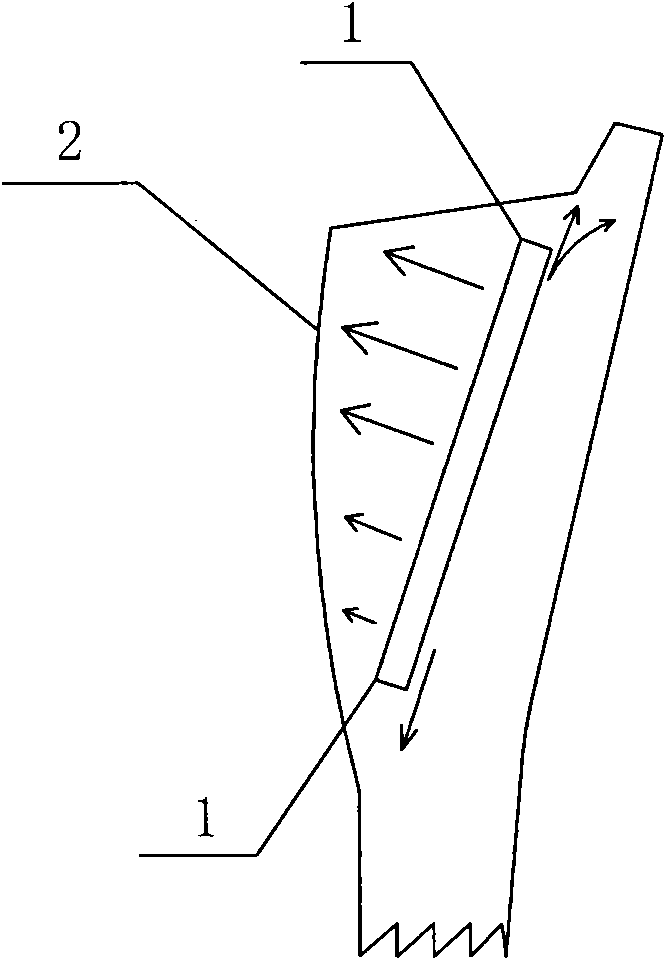

[0060] Step 2: When pressing the front body, hold down the strap 1 of the turning point with one hand, and press the strap 1 of the collar with the other hand, pull out the strap 2 as far as possible and press.

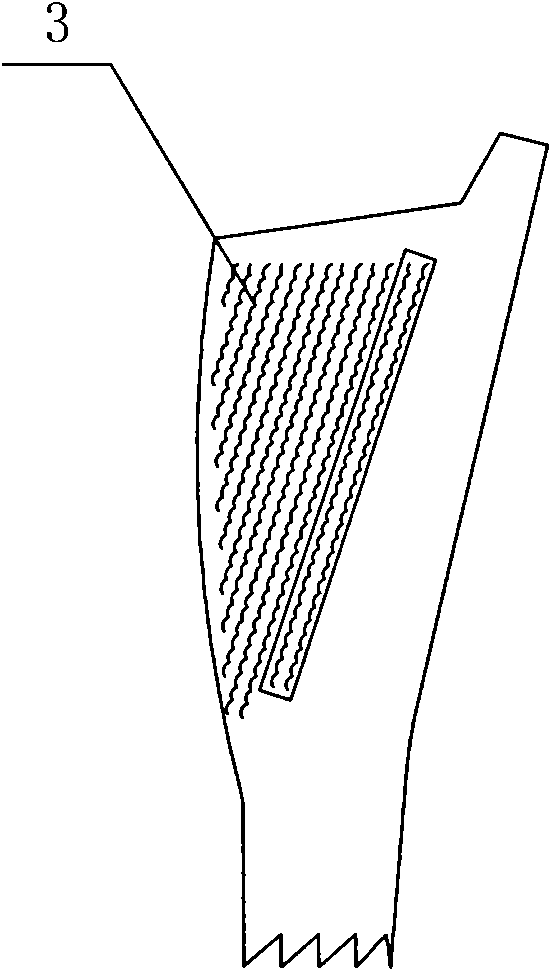

[0061] Step 3: When prying the barge, turn the barge 2 upside down and put it on the barge machine, so that the chest lining 6 is fixed to the face, and the stitches are required to be even and not seep out.

[0062] Step 4: To trim the lapel, first use the seam setting template to mark the line, then align the left and right pieces up and down and place them on the table for trimming, and punch out the collar point knife eye 41 and turning barge knife...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com