Filament forming process for paper making method-based reconstituted tobacco and device thereof

A technology for reconstituted tobacco leaves and papermaking method, which is applied in the field of papermaking reconstituted tobacco shredding process and equipment, can solve the problem that the reconstituted tobacco leaves are difficult to be shredded by the papermaking method, and achieves good looseness, improved width uniformity, and uniform length. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

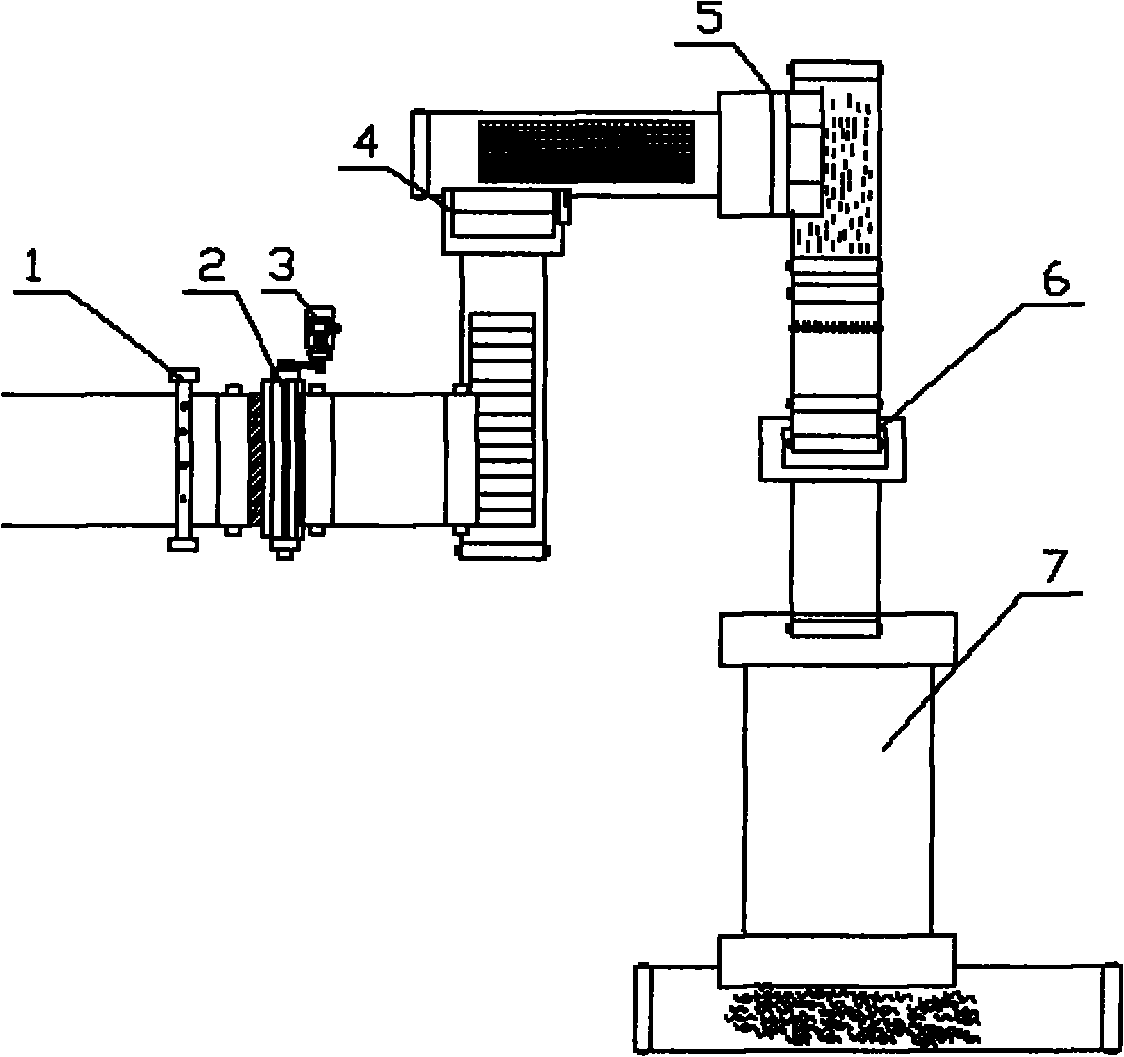

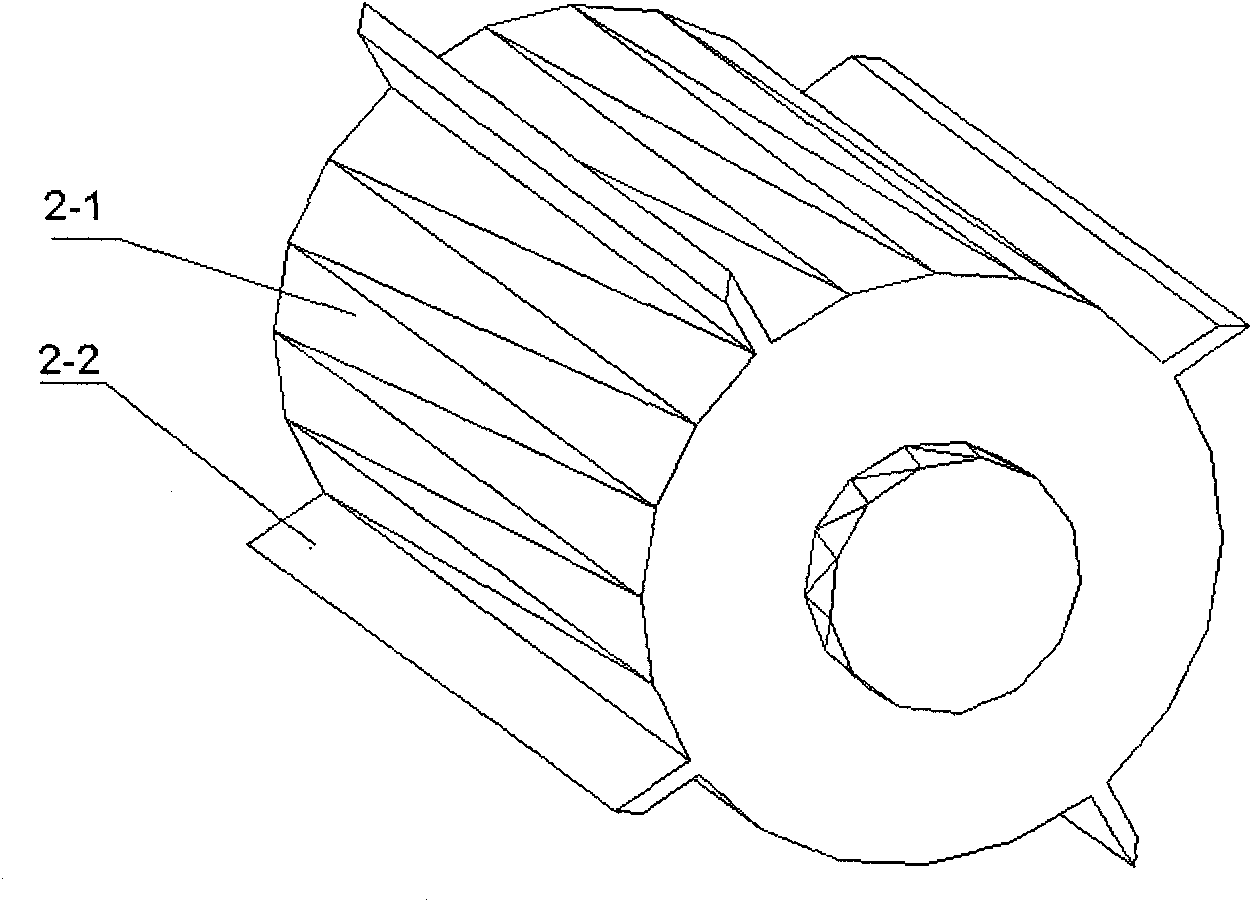

[0023] The present invention will further describe the shredded process and equipment of reconstituted tobacco leaves by papermaking method in conjunction with the accompanying drawings:

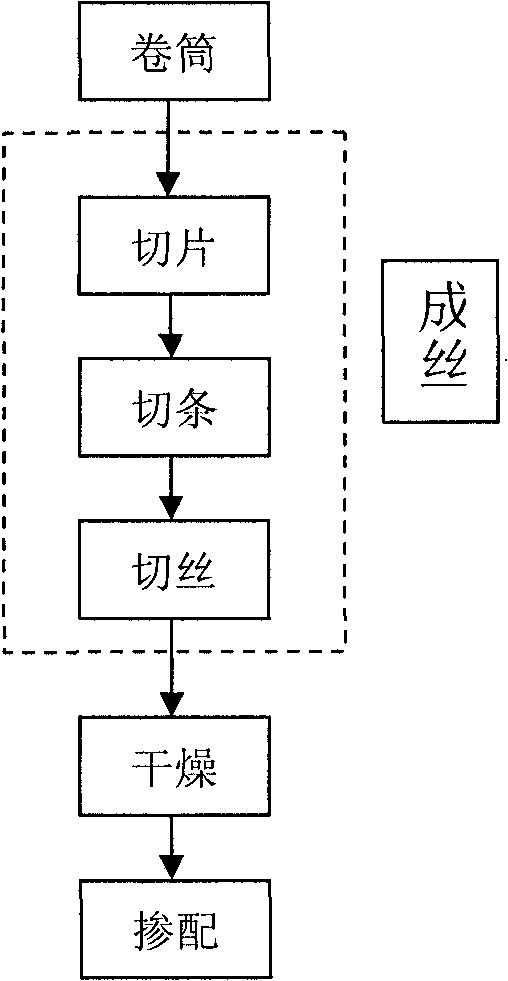

[0024] like figure 1 Shown: papermaking method reconstituted tobacco leaf of the present invention is made into shreds process and comprises reel, into shreds, drying, blending operation, and each operation specific step is as follows:

[0025] 1. Reel: transfer the dried reconstituted tobacco leaves (with a moisture content of 16% to 20%) to the reel machine and roll them into tubes. The length of the reconstituted tobacco leaves rolled into tubes is 500-1000m, and the diameter of the tubes is 1.0- 2.0m. This process is an optional process, and the dried reconstituted tobacco leaves can also be directly shredded without this process. The reconstituted tobacco reel process has two functions. On the one hand, it can stabilize the production of reconstituted tobacco. When the reconstituted ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com