Vertical shower type MOCVD reactor

A spray type, reactor technology, applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., to achieve the effect of eliminating disturbance, improving growth quality, and eliminating gas phase parasitic reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

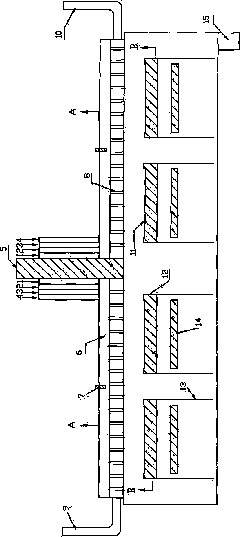

[0030] The invention designs a novel rotating shower head-isolated substrate holder MOCVD reactor, especially improves the structure of the shower head and substrate holder used in the reactor. The shower head of the reactor rotates, and the reaction gas is sprayed from different areas; each substrate holder is isolated and distributed under the nozzle in a ring shape, and the substrate holder is fixed and does not rotate. The invention can effectively prevent the occurrence of pre-reaction, realize the growth of high-quality compound semiconductor materials (such as AlN, AlGaN, etc.), eliminate the inhomogeneity of thickness and composition between substrates, realize the growth of repeating units, and then expand the reactor infinitely capacity.

[0031] The vertical spray MOCVD reactor mainly includes a reaction chamber, a spray head, a substrate support, a heating system, an inlet and an exhaust port, and a cooling water inlet and outlet. The reaction chamber is cylindric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com