Preparation method of hafnium oxide powder with nano-porous structure

A nano-pore structure, hafnium oxide technology, applied in the field of nano-powder materials, can solve the problems of poor thermal stability of hafnium dioxide, irregular changes in pore size, underdeveloped pores, etc., and achieves high dispersion, simple operation, and large ratio. The effect of surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Using hafnium tetrachloride and benzoic acid as raw materials, mix them at a molar ratio of 1:2, ball mill them evenly, and then calcinate at 700°C for 2 hours to obtain hafnium oxide powder with a nanoporous structure.

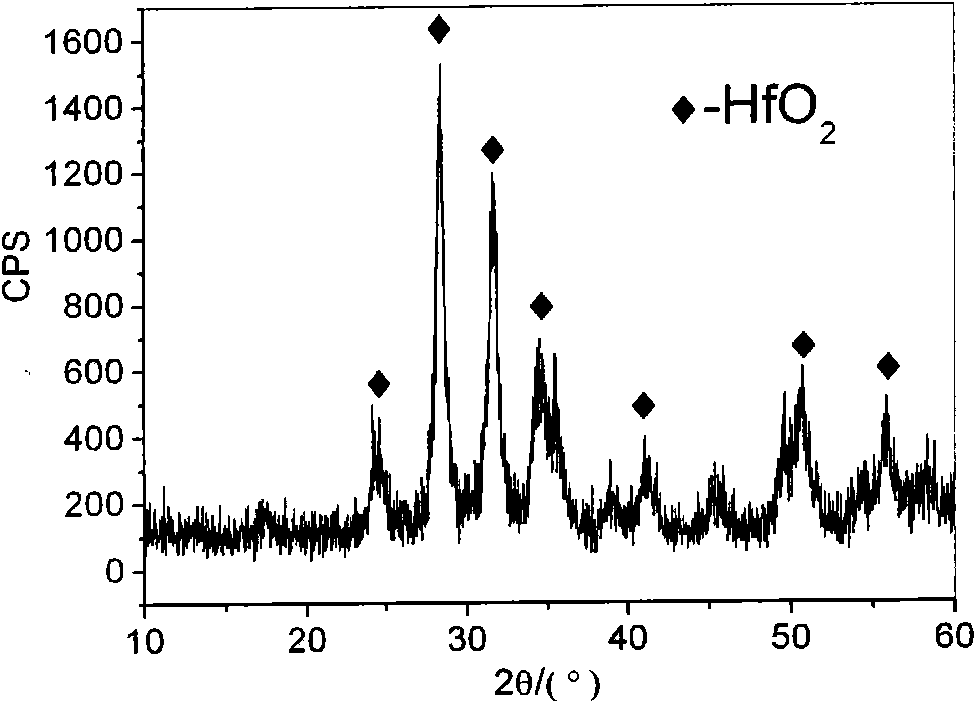

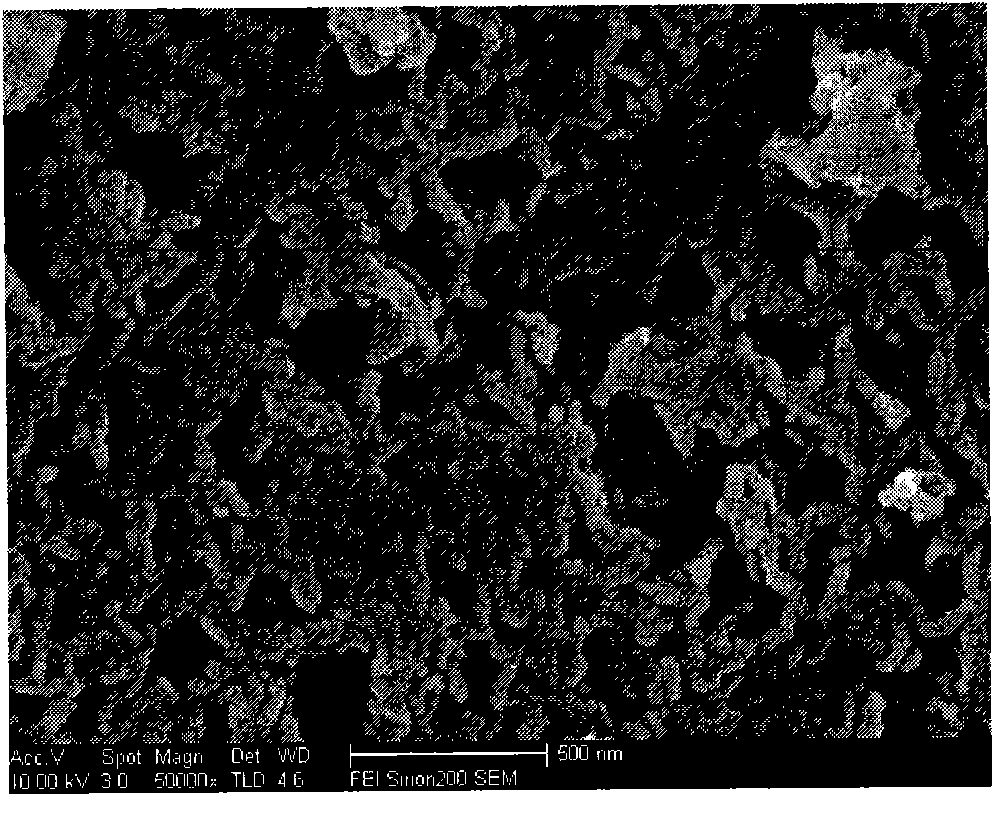

[0013] By XRD test, it can be seen that the powder crystal type is a monoclinic phase (see figure 1 ); through SEM testing, it can be seen that the hafnium oxide powder has a three-dimensional network, the pore size is 50-100nm, and the skeleton particles are 20-100nm (see figure 2 ).

Embodiment 2

[0015] Using hafnium tetrachloride and benzoic acid as raw materials, mix them at a molar ratio of 1:3, ball mill them evenly, and then calcinate at 500°C for 2 hours to obtain hafnium oxide powder with a nanoporous structure.

Embodiment 3

[0017] Using hafnium tetrachloride and benzoic acid as raw materials, mix them at a molar ratio of 1:4, ball mill them evenly, and then calcinate at 800°C for 2 hours to obtain hafnium oxide powder with a nanoporous structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com