Slide type cutting machine

A cutting machine, sliding technology, applied in sawing equipment, metal sawing equipment, sawing machine devices, etc., can solve the problems of sudden approach of the saw, troublesome assembly operations, and large number of parts, so as to achieve miniaturization and prevent interference. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Hereinafter, preferred embodiments for carrying out the present invention will be described using the drawings. The following embodiments are not limited to the inventions of the respective claims, and all combinations of the features described in the embodiments are not necessarily limited to the solution means of the invention.

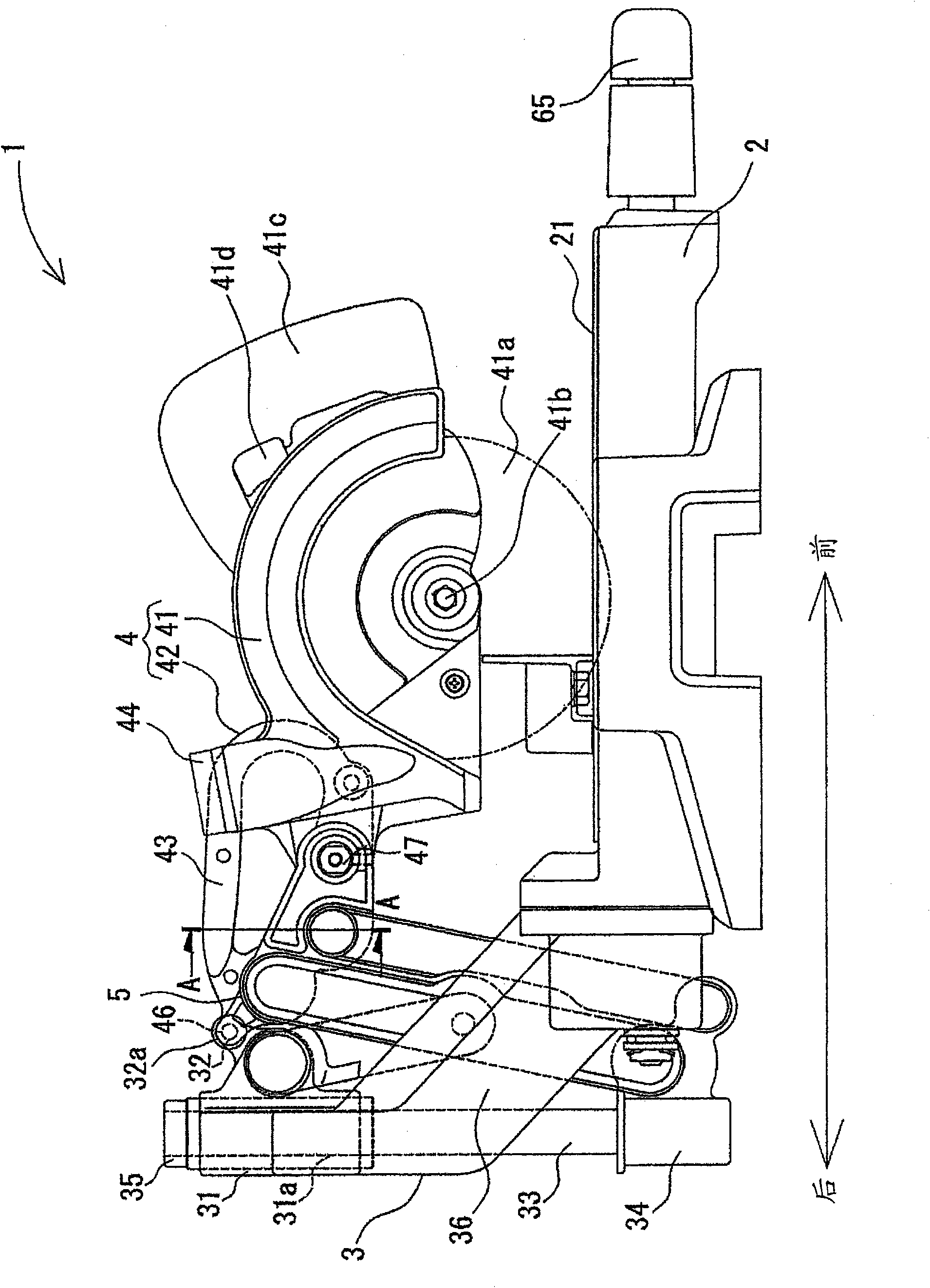

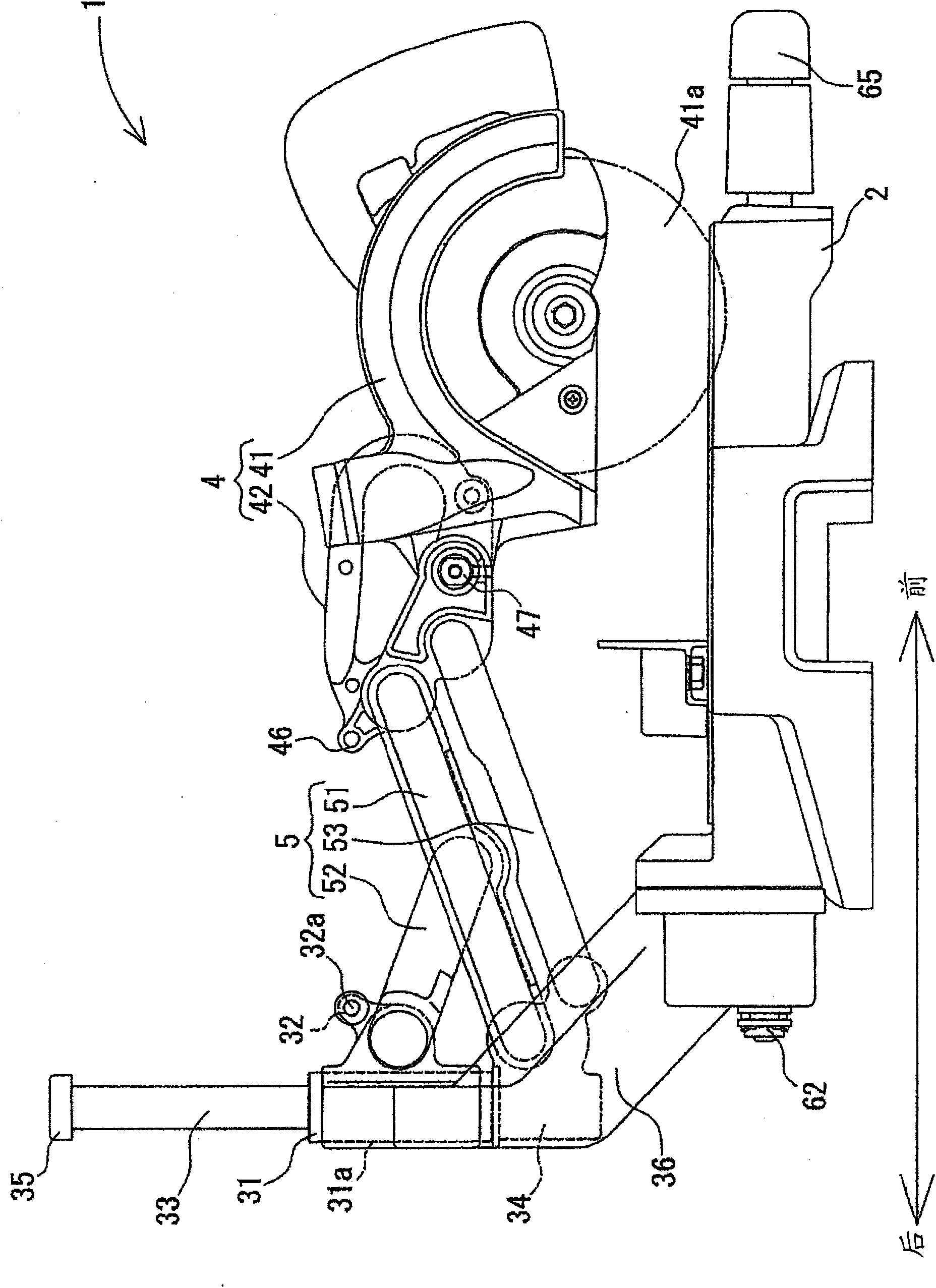

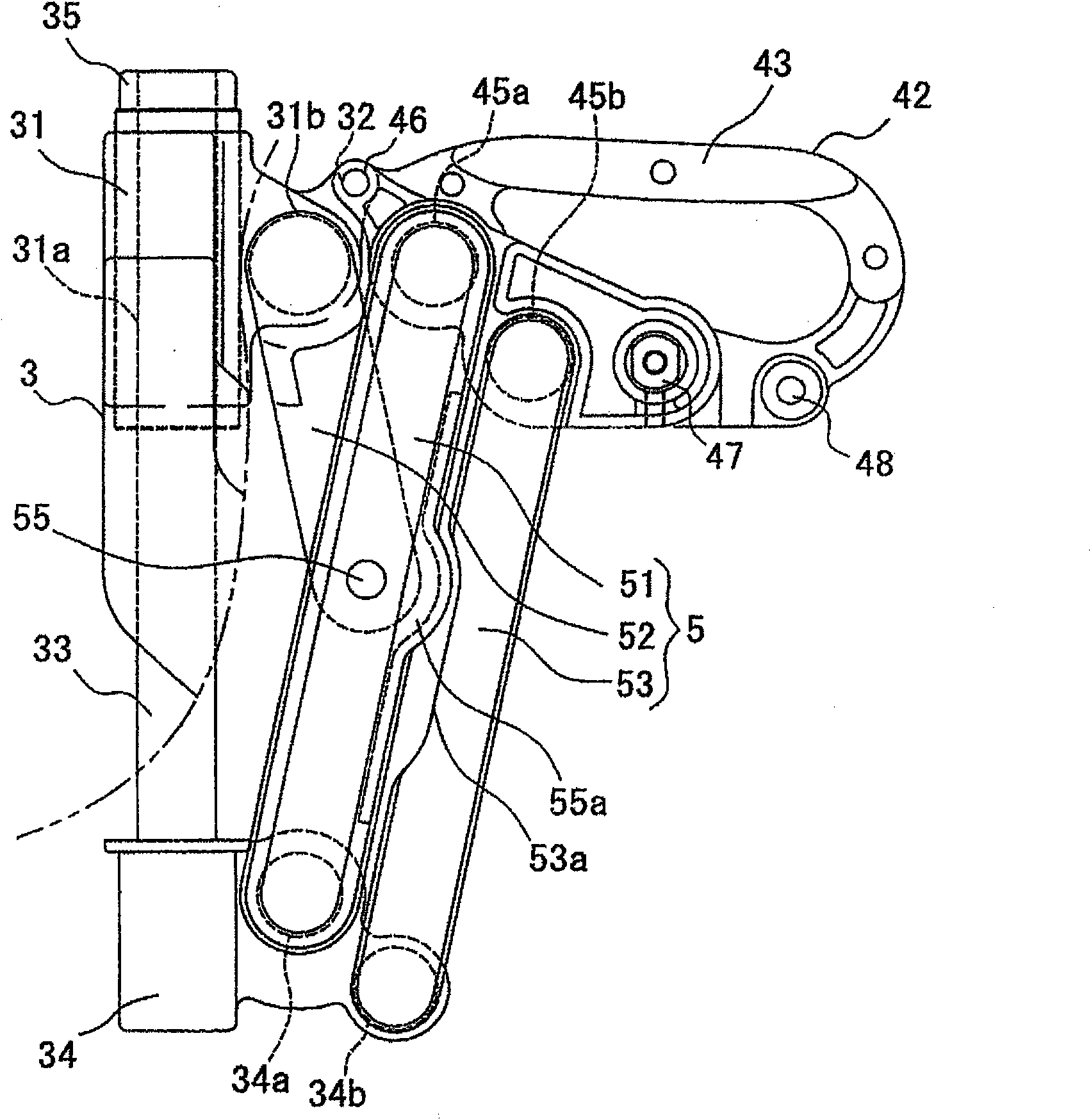

[0057] figure 1 It is a side view showing the overall structure of the sliding cutting machine according to this embodiment; figure 2 It is a side view showing the state where the cutting unit is moved to the operator's side; image 3 It is an enlarged view showing the coupling mechanism of the sliding cutter of this embodiment; Figure 4 It is a top view showing the overall structure of the sliding cutting machine according to this embodiment; Figure 5 It is a rear view showing the tilting movement mechanism of the linear guide device of the sliding cutting machine; Figure 6 yes figure 1 The A-A section diagram.

[0058] In addition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com