Method for passivating cavity surface of GaAs-based semiconductor laser

A laser and semiconductor technology, applied in the direction of semiconductor lasers, lasers, laser components, etc., can solve the problems of high instrument cost, unsatisfactory oxidation and interface state removal effect, complex vacuum cleavage technology, etc., to achieve simple steps, reduce non-destructive Effects of radiation recombination and cavity surface heating, improvement of COD and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

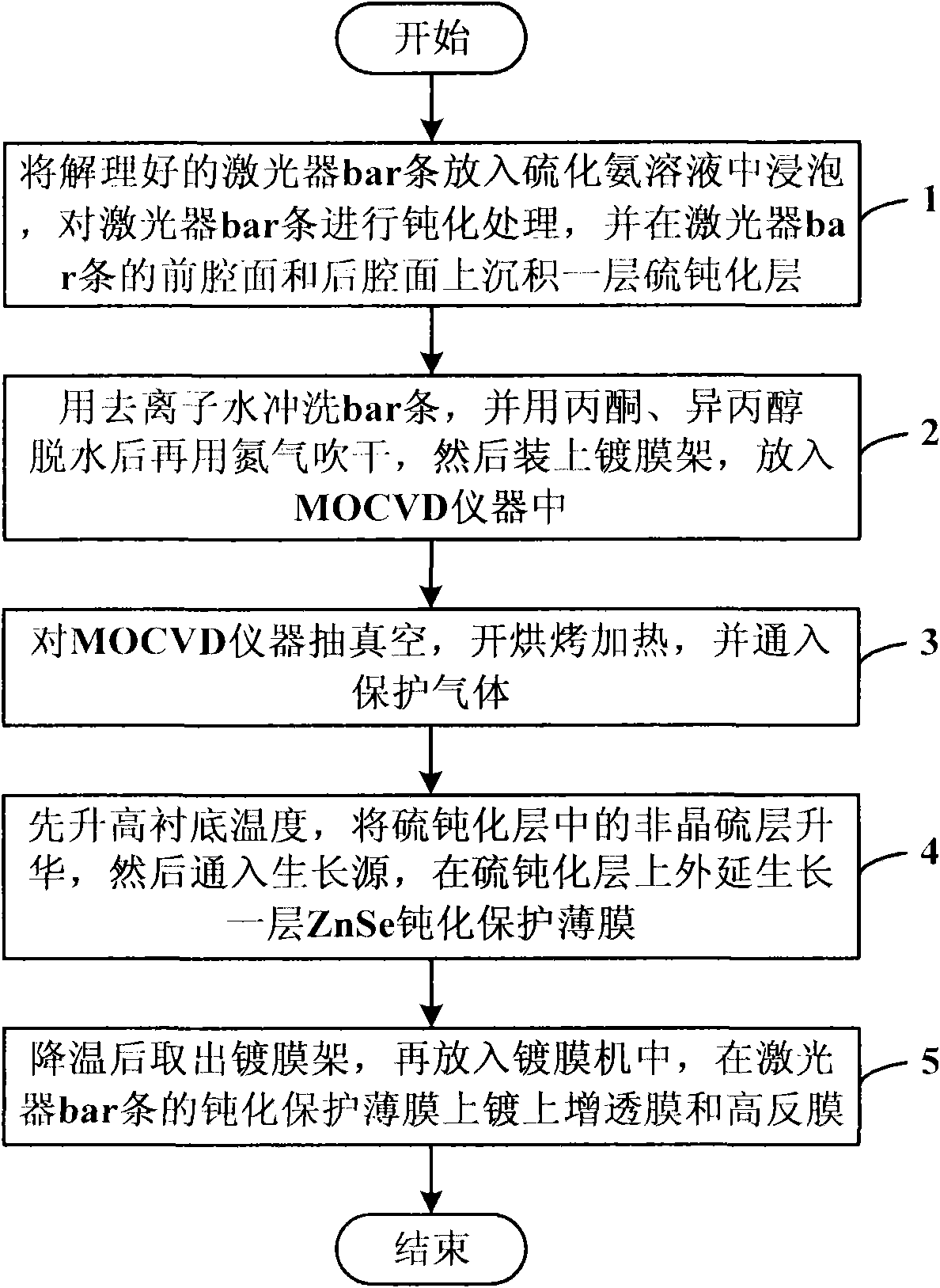

[0027] Such as figure 1 as shown, figure 1 The method flowchart of the cavity surface passivation of the GaAs-based semiconductor laser provided by the present invention, the method comprises:

[0028] Step 1: Soak the cleaved laser bar in ammonia sulfide solution, passivate the laser bar, and deposit a sulfur passivation layer on the front and rear cavity surfaces of the laser bar;

[0029] Step 2: Rinse the bar with deionized water, dehydrate it with acetone and isopropanol, then blow it dry with nitrogen, then install it on the coating rack and put it into the MOCVD instrument;

[0030] Step 3: Vacuum the MOCVD instrument, turn on the baking and heating, and pass in the protective gas;

[0031] Step 4: first raise t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com