Monolithic ceramic tube and preparation method thereof

A ceramic tube and monolithic technology, applied in tubular capacitors, components of fixed capacitors, dielectrics of fixed capacitors, etc., can solve the problems of poor electrical performance indicators and resistance to external forces, heavy production equipment, and large investment. Achieve the effect of small size of production equipment, low energy consumption and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

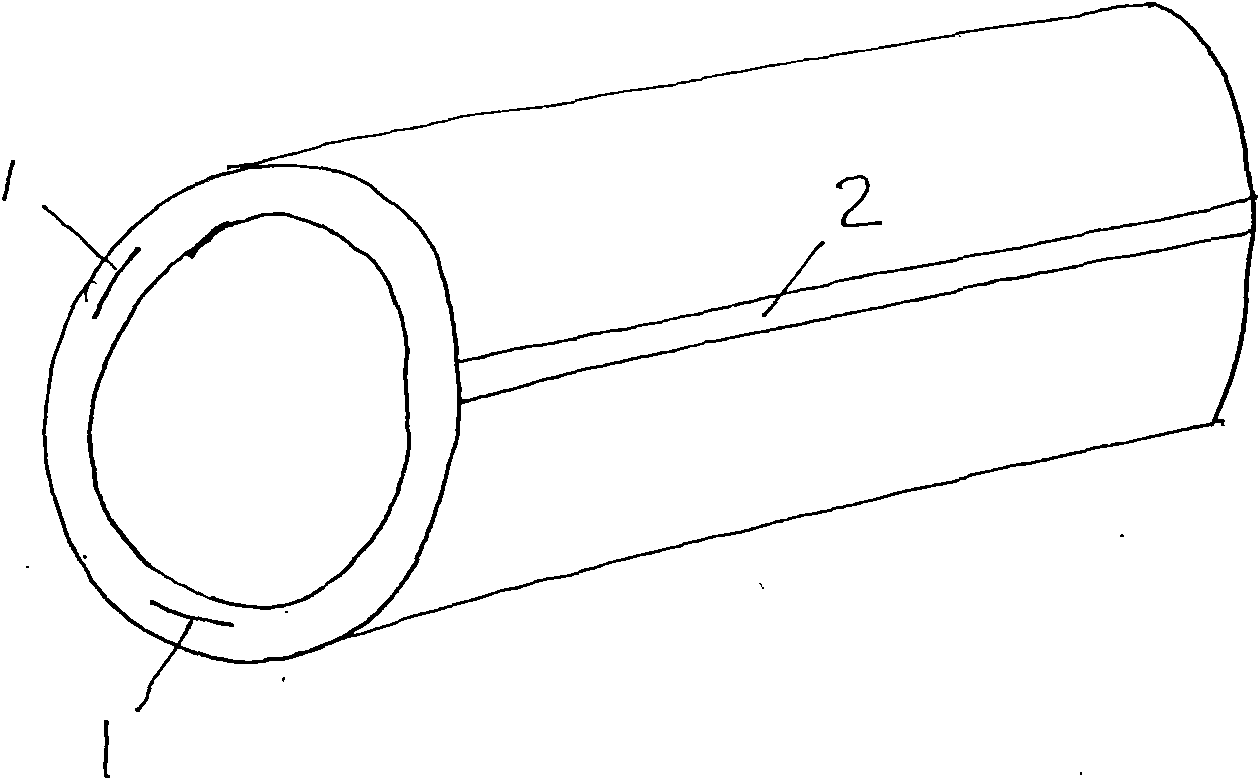

[0029] Such as image 3 As shown, there are two axially embedded electrodes 1 in the wall thickness of the monolithic ceramic tube, and one axially external electrode 2 on the outer wall surface.

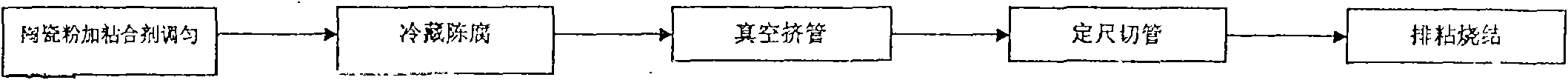

[0030] The preparation process of the monolithic ceramic tube is as follows:

[0031] Ultra-thin (0.003mm) flexible ceramic diaphragm (choose material X7R or NPO diaphragm according to the requirements of the drawing) is spread on the glass plate, and cut according to the size of the drawing with a ruler or a utility knife; (2) Melt paraffin at 40°C±2 ℃Apply evenly on the surface of the printing transfer plate, and spread the film on the plate surface; (3) Hold both ends of the printing transfer plate, put it into the positioning pin of the screen printing machine, and print several parallel embedded electrodes (palladium silver E2369) on the film ;(4) Put the printing transfer plate and the diaphragm into the electric oven, bake at 40°C-50°C for 25-30 minutes and take it out; Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com