Detecting and setting device on production line of electric energy meters

An electric energy meter and production line technology, applied in the field of detection and setting devices, can solve the problems of low production efficiency, low reliability of production process, low degree of automation, etc., and achieve the effects of high work efficiency, high reliability and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

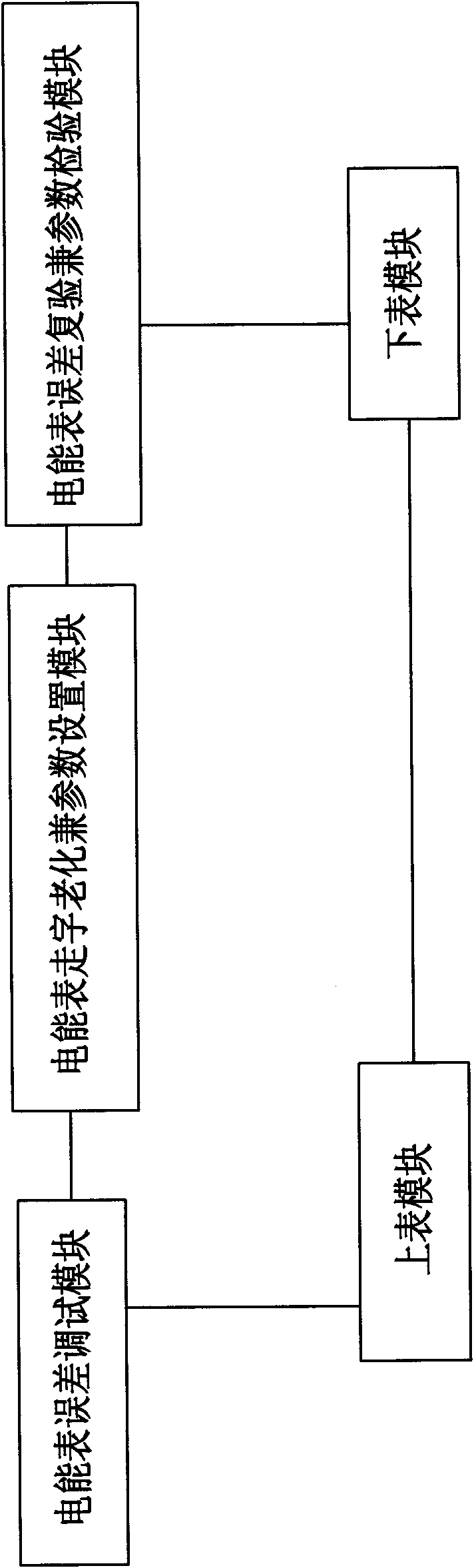

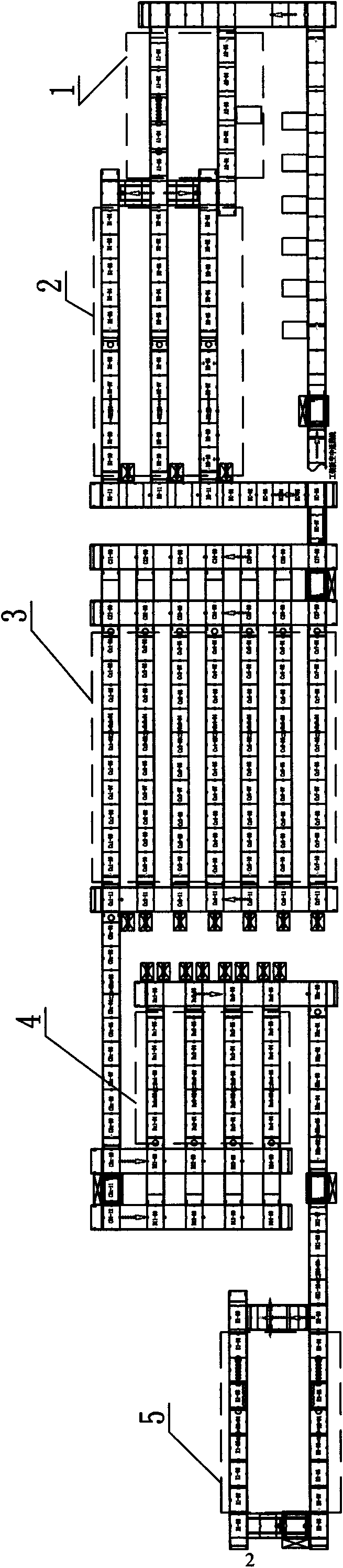

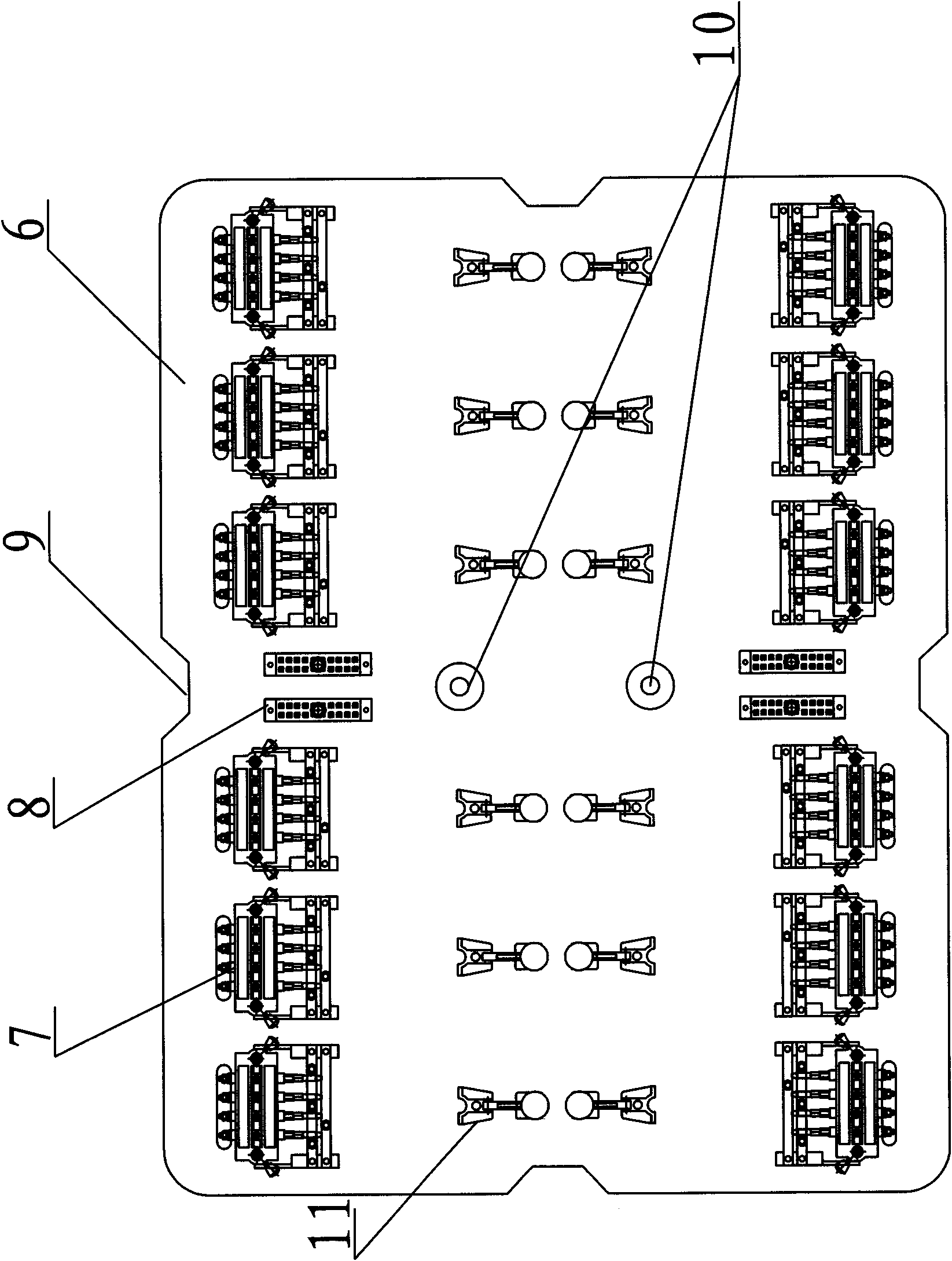

[0021] The detection and setting device on the electric energy meter production line of the present invention includes an upper table module 1, an electric energy meter error debugging module 2, an electric energy meter aging and parameter setting module 3, an electric energy meter error rechecking and parameter inspection module 4, and a lower table module 5. Conveying lines are provided between adjacent modules and between module 1 in the upper table and module 5 in the lower table, and each module includes at least one conveying line, which is connected to the adjacent conveying line between the modules; The conveying line is provided with a pallet carrying an electric energy meter, and the conveying line is also provided with a position sensor and a limit unit for limiting the position of the pallet; the conveying line in the above-mentioned module is equipped with an el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com