Automatic control device of oil pipe clamping mechanism of non-well killing workover rig

A technology of automatic control device and clamping mechanism, which is applied to the automatic control system of drilling, wellbore/well components, oil traps, etc., which can solve the problems of no system safety guarantee, difficult pipeline layout, poor maintainability, etc., and achieve improved Safety, simple layout of network cables, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is illustrated below by an example.

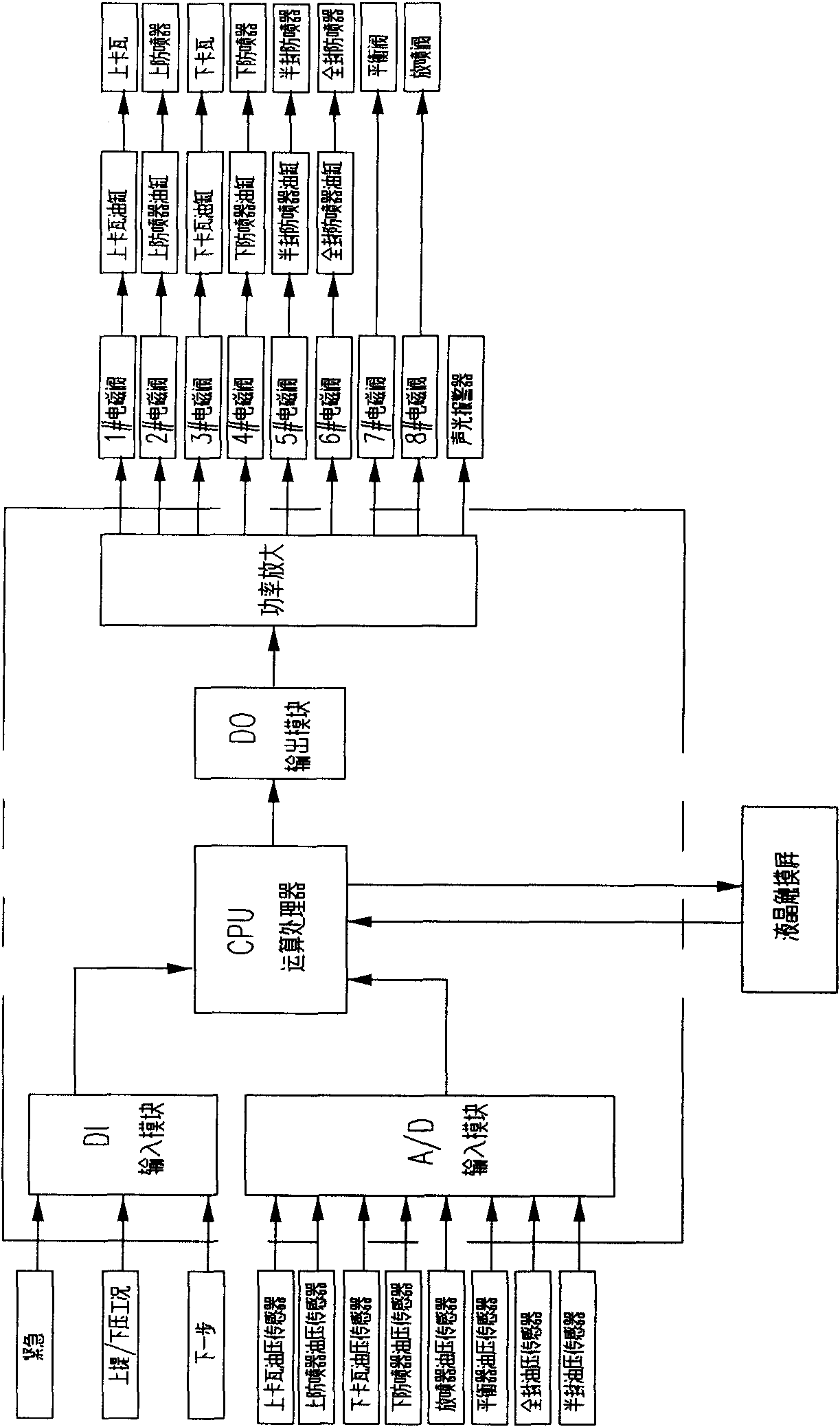

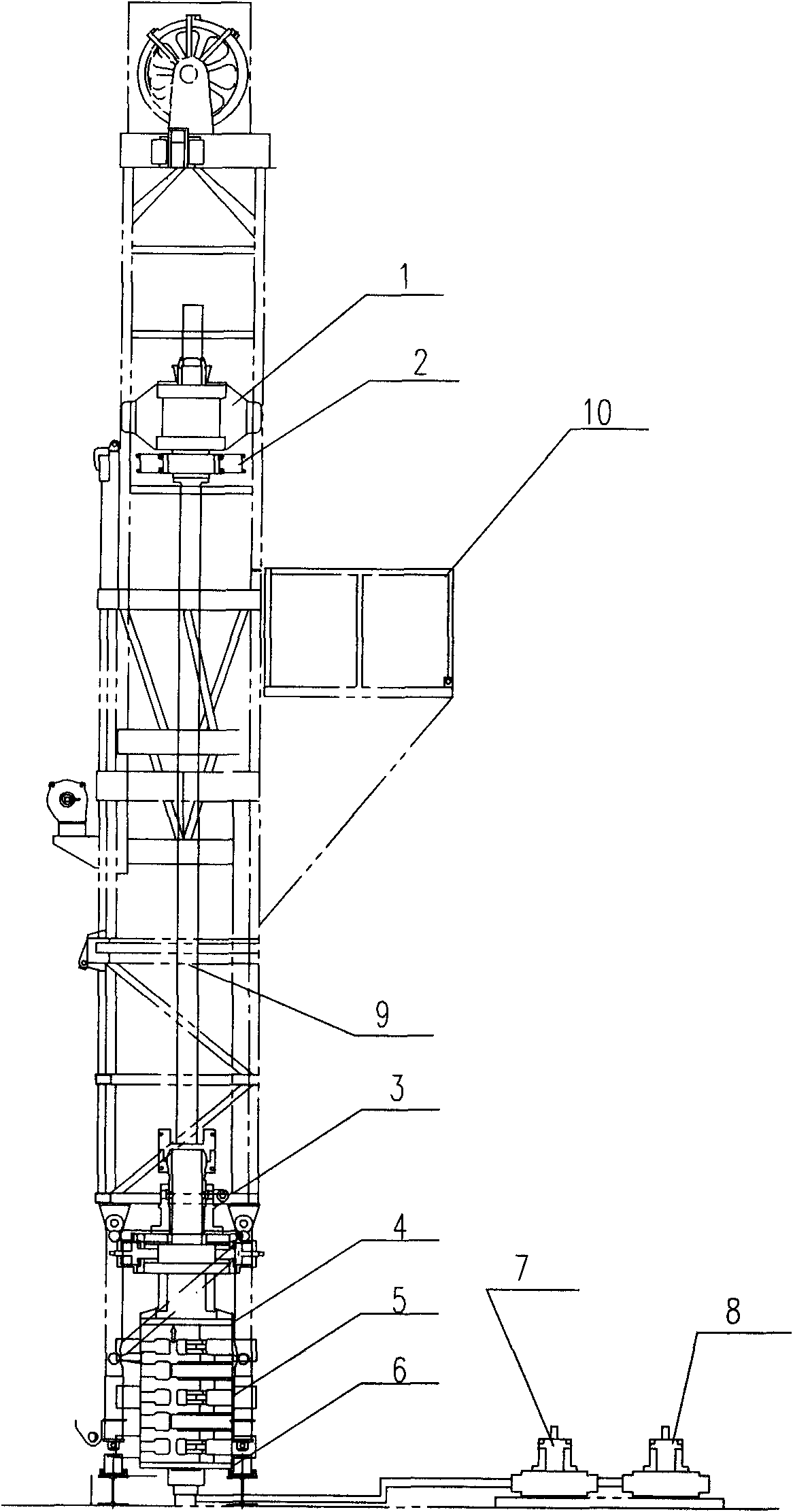

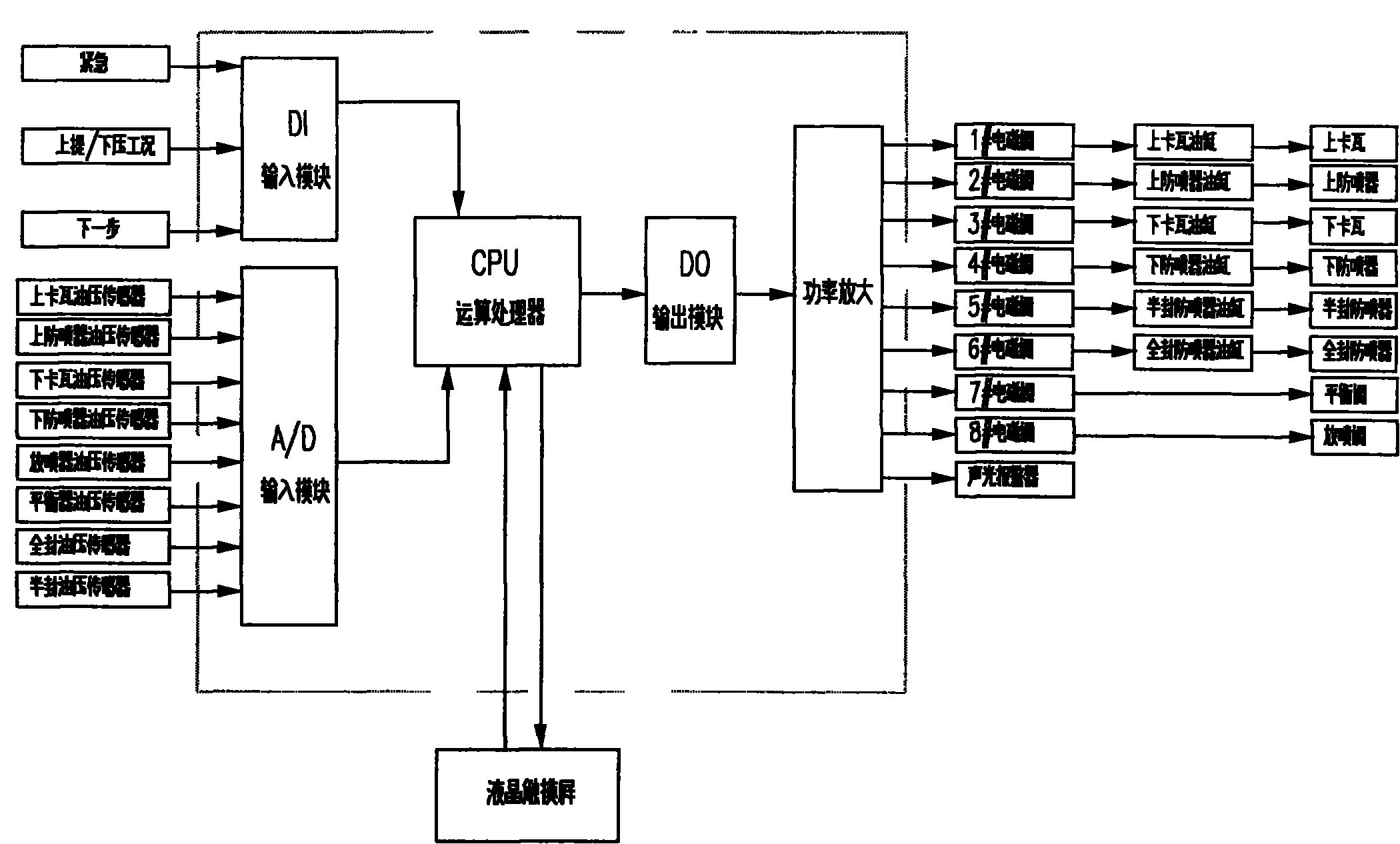

[0015] see figure 1 , figure 2 , during the snubbing workover operation, a tubing clamping mechanism is set in the movement path of the tubing 9 so that the tubing 9 can be clamped in an orderly manner. The tubing clamping mechanism consists of the upper slip 1 and the upper blowout preventer 2 , lower slip 3, lower blowout preventer 4, semi-sealed blowout preventer 5, full-seal blowout preventer 6, balanced shut-off valve 7, blowout shut-off valve 8, etc. The above-mentioned device is connected with the corresponding hydraulic control cylinder through the cam mechanism, and is connected with the eight solenoid valves installed on the platform one by one. At the same time, eight oil pressure sensors are installed one by one on the hydraulic inlet pipe of the above-mentioned oil cylinder and valve On the road, three operating switches of "uplift / down", "next step" and "emergency stop" are installed on the ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com