Method for exploiting natural gas hydrates by using high-pressure thermal jetting

A natural gas and hydrate technology, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of large heat loss, small mining range, and little contribution to the decomposition of natural gas hydrate, so as to ensure cutting, Good heat conduction effect, overcome self-protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

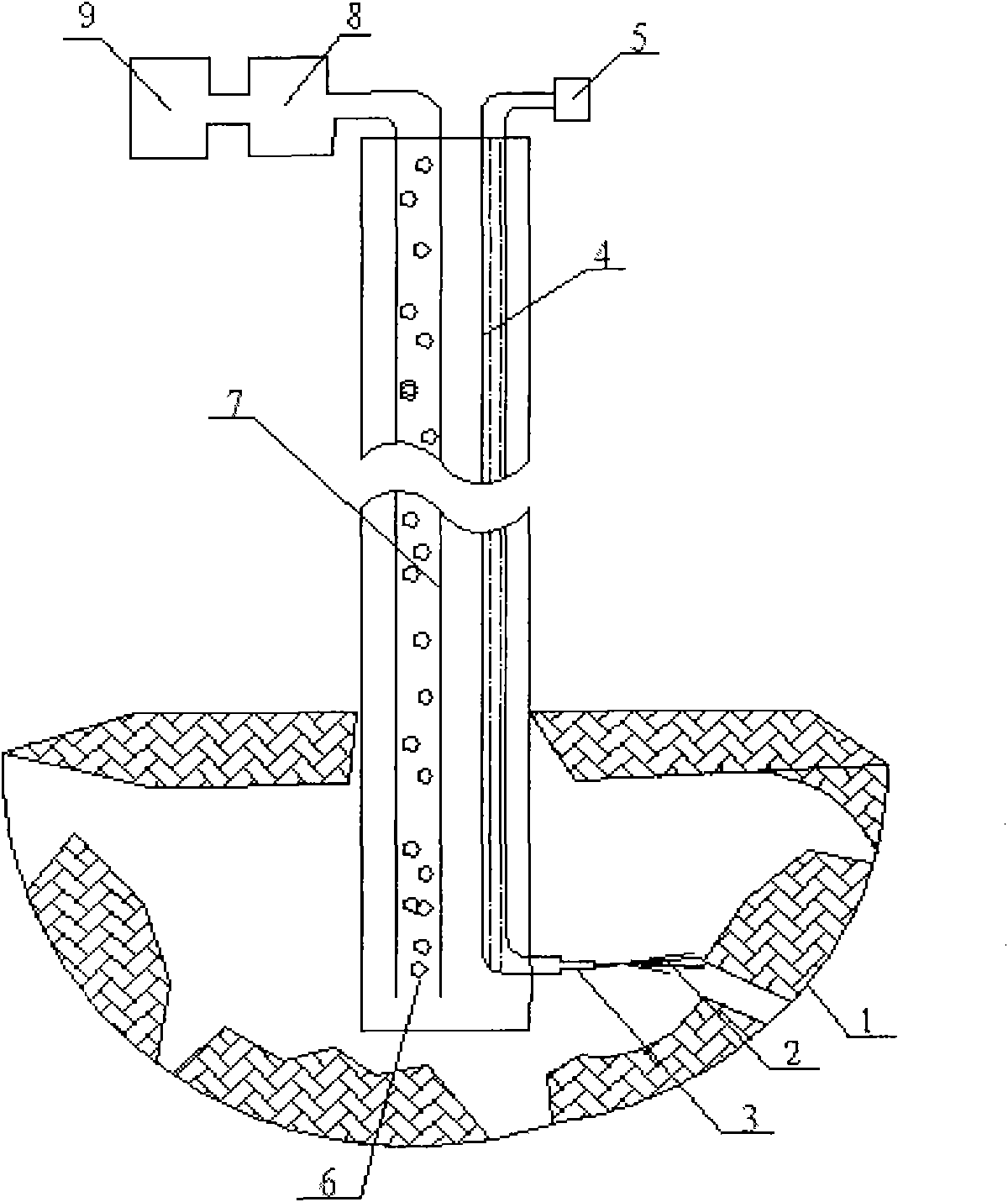

[0021] a. Using a core drilling rig to drill a production well on the geological body where the natural gas hydrate is pre-exploited;

[0022] b. Send the water injection pipe 4 and the telescopic water gun 3 into the production well together with the production pipe 7 after threaded connection;

[0023] c. The exploitation pipe 7 is connected with the gas-liquid separation device 8 through threads, and the gas-liquid separation device 8 is connected with the gas recovery device 9 through threads;

[0024] d. The hot fluid 2 with a pressure of 10MPa, a flow velocity of 300m / s, and a temperature of 80°C is sent through the high-pressure pump 5 into the water injection pipe 4 and the retractable water gun 3 to generate a high-speed jet to act on the natural gas hydrate 1;

[0025] e. The high-speed jet directly acts on the natural gas hydrate 1 within its working radius, so that the natural gas hydrate 1 is cut and decomposed, and the undecomposed natural gas hydrate, natural ga...

Embodiment 2

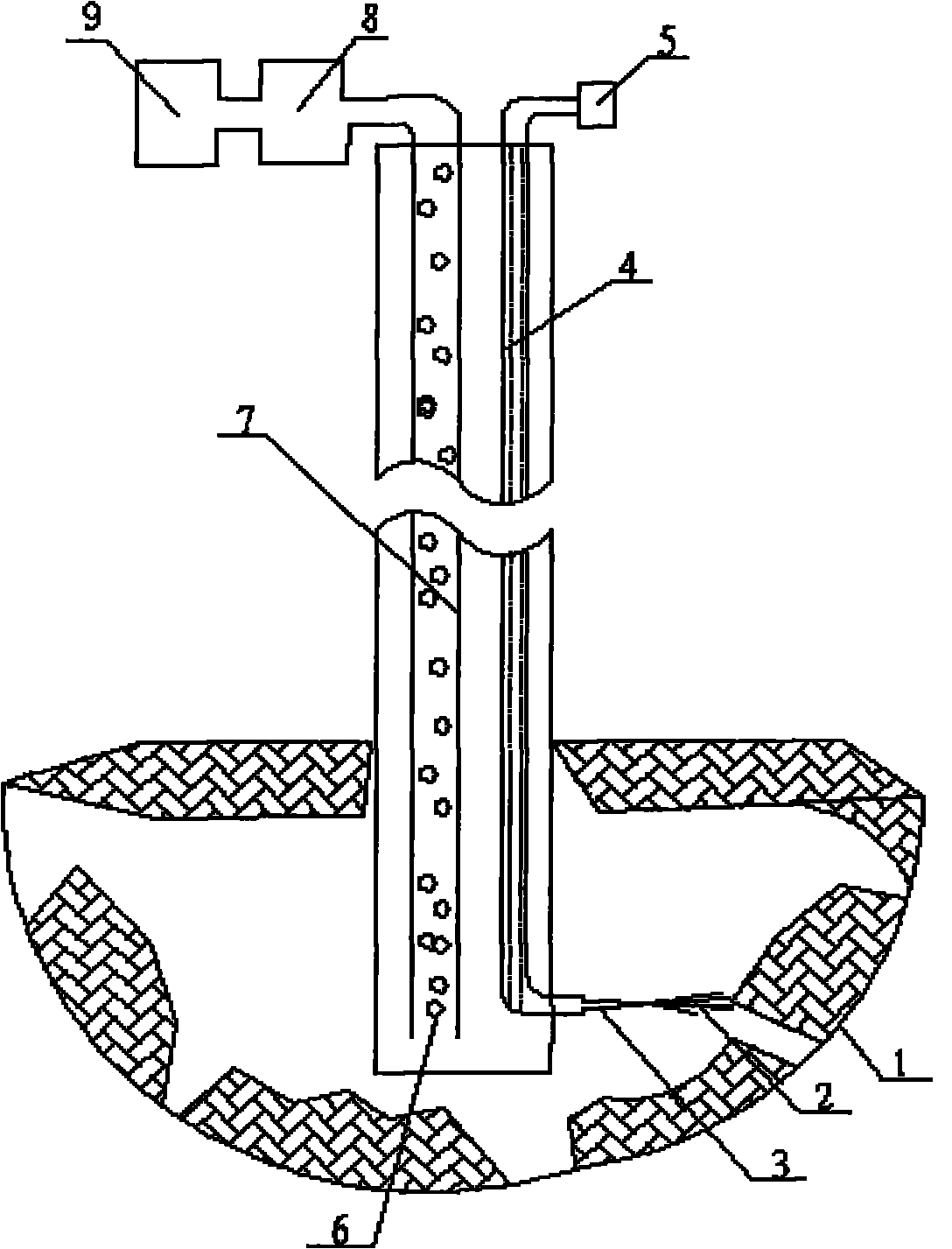

[0030] a. Using a core drilling rig to drill a production well on the geological body where the natural gas hydrate is pre-exploited;

[0031] b. Send the water injection pipe 4 and the telescopic water gun 3 into the production well together with the production pipe 7 after threaded connection;

[0032] c. The exploitation pipe 7 is connected with the gas-liquid separation device 8 through threads, and the gas-liquid separation device 8 is connected with the gas recovery device 9 through threads;

[0033] d. The hot fluid 2 with a pressure of 20MPa, a flow velocity of 300m / s, and a temperature of 65°C is sent through the high-pressure pump 5 into the water injection pipe 4 and the retractable water gun 3 to generate a high-speed jet to act on the natural gas hydrate 1;

[0034] e. The high-speed jet directly acts on the natural gas hydrate 1 within its working radius, so that the natural gas hydrate 1 is cut and decomposed, and the undecomposed natural gas hydrate, natural ga...

Embodiment 3

[0037] a. Using a core drilling rig to drill a production well on the geological body where the natural gas hydrate is pre-exploited;

[0038] b. Send the water injection pipe 4 and the telescopic water gun 3 into the production well together with the production pipe 7 after threaded connection;

[0039] c. The exploitation pipe 7 is connected with the gas-liquid separation device 8 through threads, and the gas-liquid separation device 8 is connected with the gas recovery device 9 through threads;

[0040] d. Send the thermal fluid 2 with a pressure of 30MPa, a flow velocity of 300m / s, and a temperature of 50°C through the high-pressure pump 5 into the water injection pipe 4 and the retractable water gun 3 to generate a high-speed jet to act on the natural gas hydrate 1;

[0041] e. The high-speed jet directly acts on the natural gas hydrate 1 within its working radius, so that the natural gas hydrate 1 is cut and decomposed, and the undecomposed natural gas hydrate, natural g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com