Construction method of sunlight greenhouse

A technology of solar greenhouse and construction method, which is applied in the directions of greenhouse cultivation, building structure, botanical equipment and methods, etc., can solve the problems of being limited, generally 1.8-2.2 meters, not suitable for fruit tree cultivation, and having greenhouse shading, etc. , to achieve the effect of being conducive to planting and cultivation, easy to dismantle and move, and to shorten the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

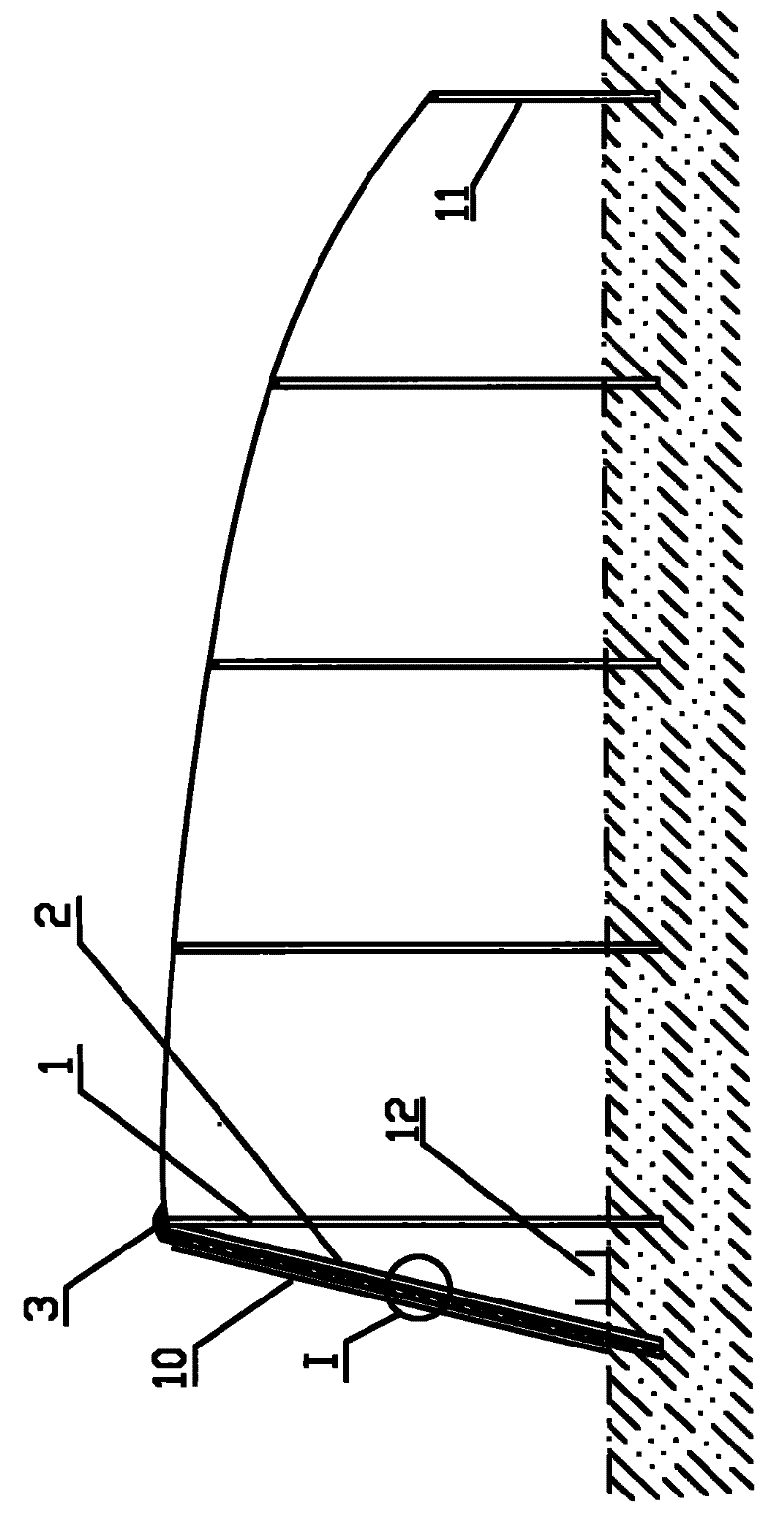

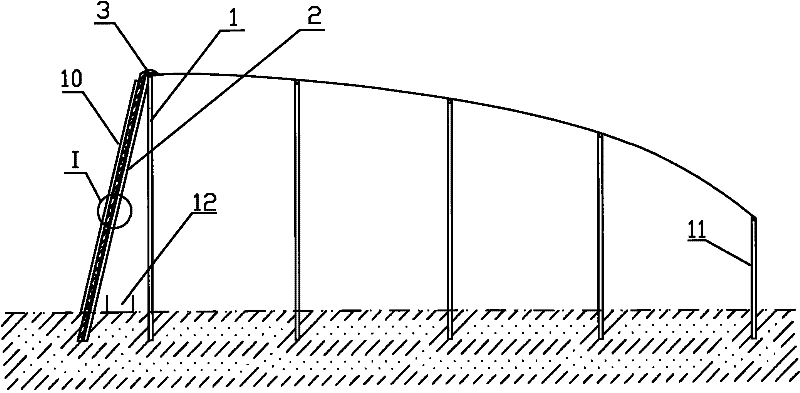

[0021] Such as figure 1 , 2 Shown, solar greenhouse construction method of the present invention, it comprises the construction of east and west gable, the construction of back wall, the roof construction step;

[0022] 1. The construction of the back wall is as follows: a right-angled triangular support frame composed of upright column 1 and slanted column 2 is buried at an interval of 1.8m along the east-west direction; The distance between the bottom of the column 1 is 1.5m; the height of the column 1 above the ground is 4m, and it is buried 0.5m underground; grooves are opened on the top surface of the column 1 along the east-west direction for installing and fixing the beam 3; :

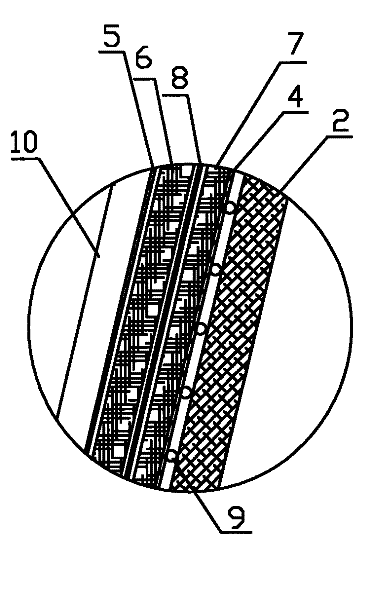

[0023] a, body of wall making: the inner and outer layers of the body of wall are polyethylene non-drip film 4,5, two layers of straw thatch 6,7 with a thickness of 8cm are laid between them, and one deck of polythene is laid between the two layers of straw thatch 6,7 Ethylene non-drip film 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com