Cold bleaching device for open-width knitted fabrics

A knitted fabric and open-width technology, applied in the field of fabric dyeing pretreatment equipment, can solve problems affecting dyeing quality, wrinkles, inconsistencies, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

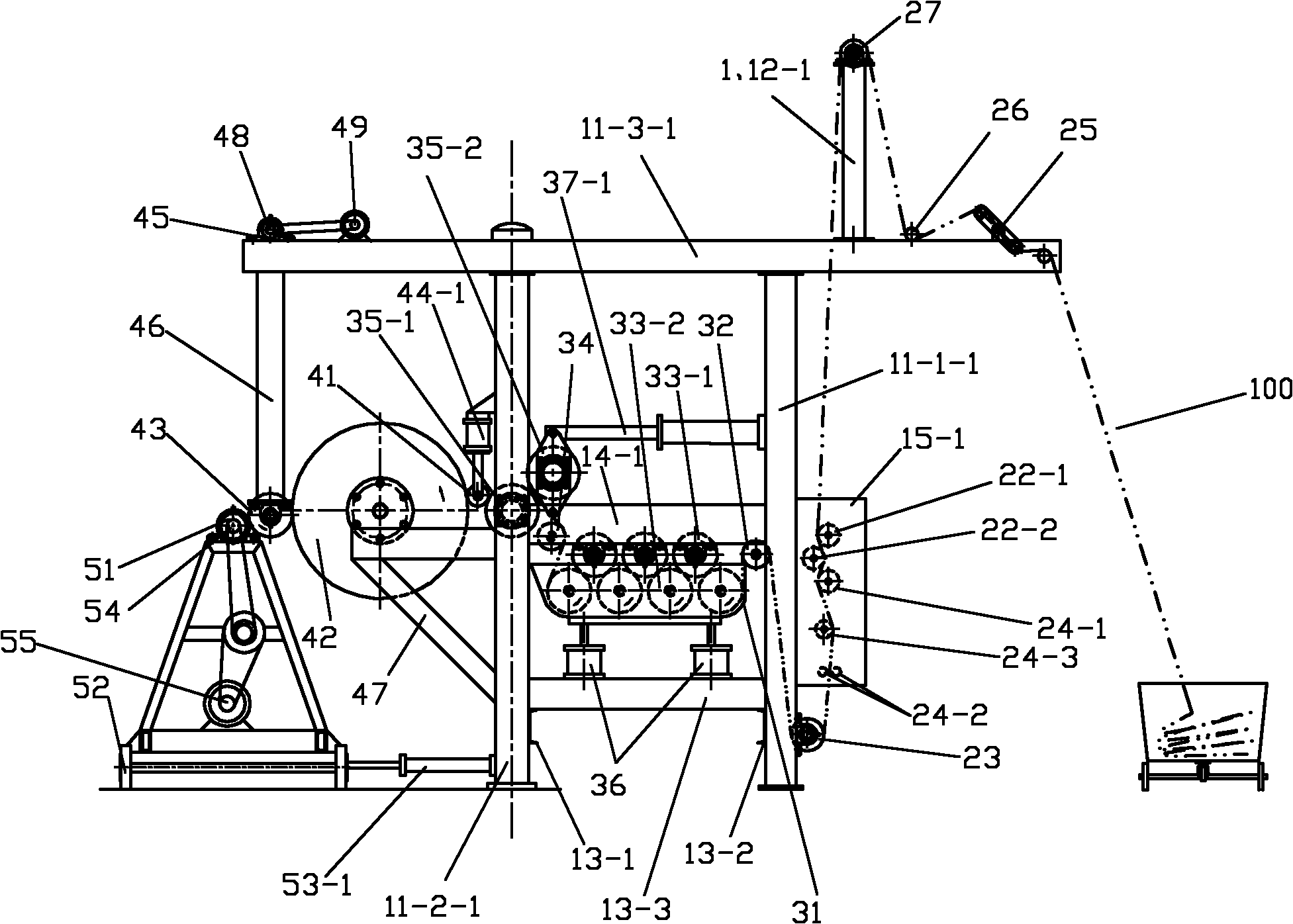

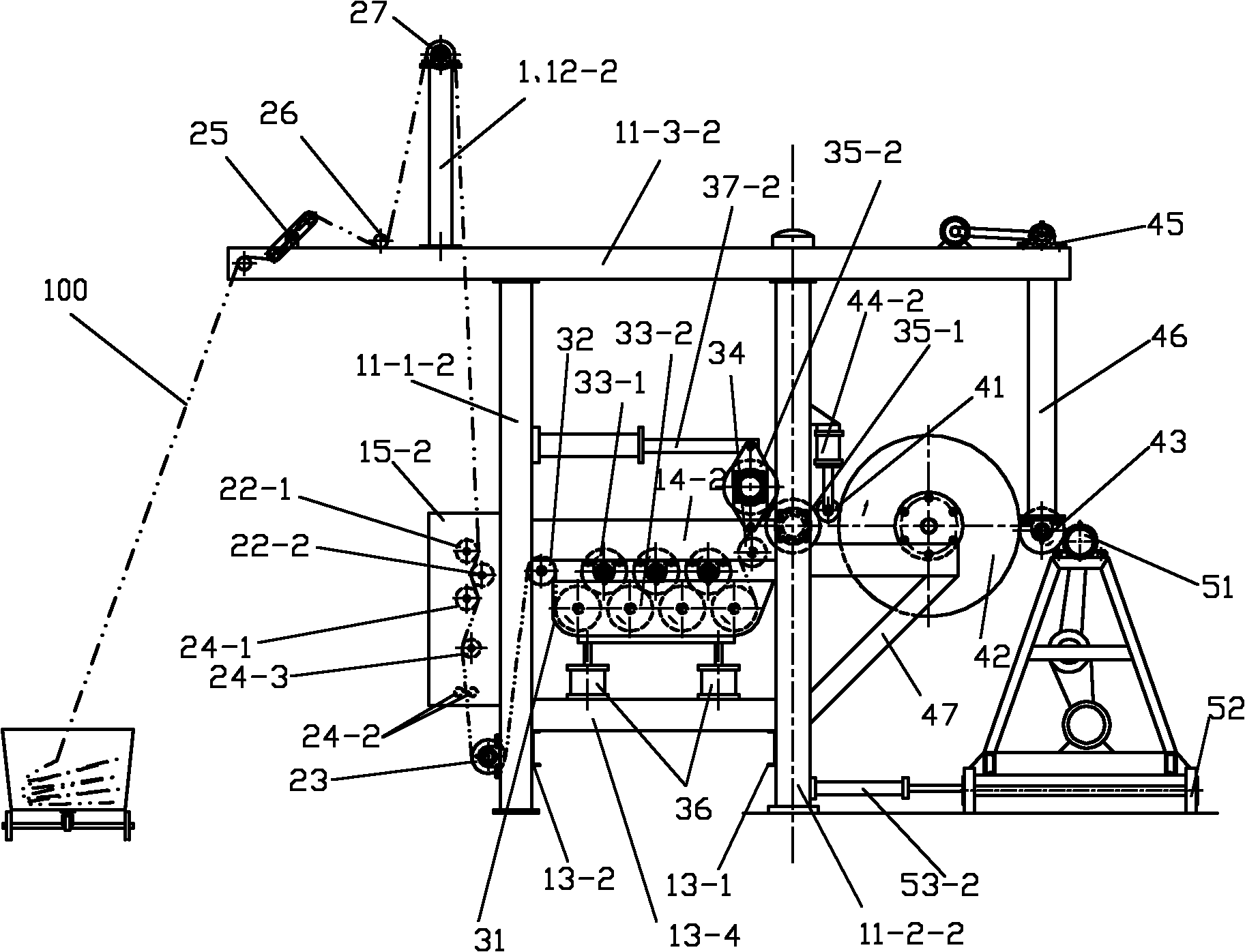

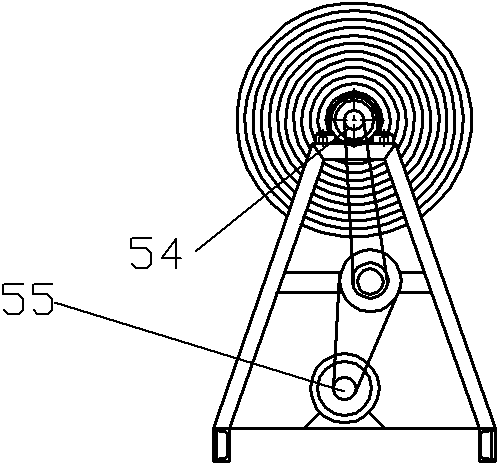

[0025] (Example 1) see figure 1 , the open-width open-width knitted fabric cold bleaching device in this embodiment includes a frame 1, a cloth feeding device 2, a liquid soaking device 3, a wet state cloth feeding device 4, a cloth rolling device 5, a liquid supply device and a control device. circuit. The cloth feeding device 2, the soaking liquid squeezing device 3, the cloth feeding device 4 and the cloth rolling device 5 are arranged sequentially on the fabric traveling route in a wet state. The various cloth guide rollers of each component are arranged according to the front and rear directions, and their respective axes are parallel to each other.

[0026] The frame part 1 includes a main frame body 11 , an upper guide roller frame 12 , a liquid immersion tank frame 13 , a liquid immersion roller frame 14 and a box body 15 .

[0027] The main frame body 11 includes 2 right vertical beams 11-1, 2 left vertical beams 11-2, 2 vertical beams 11-2, 2 horizontal beams 11-3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com