Electrodeposit nickel plating solution for deformation zinc alloy and electrodeposit nickel plating method thereof

A technology of electrodeposition and zinc alloy, which is applied in the field of electrodeposition nickel plating solution of deformed zinc alloy, can solve the problems of poor stability of the plating solution, difficulty in maintenance, affecting the performance of the plating layer and subsequent plating types, etc., and achieves long service life and stability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Each component and content thereof of the electrodeposition nickel-plating solution of a kind of wrought zinc alloy are as follows:

[0052] Nickel sulfate hexahydrate 110g / L;

[0053] Sodium chloride 12g / L;

[0054] Boric acid 30g / L;

[0055] Sodium citrate 80g / L.

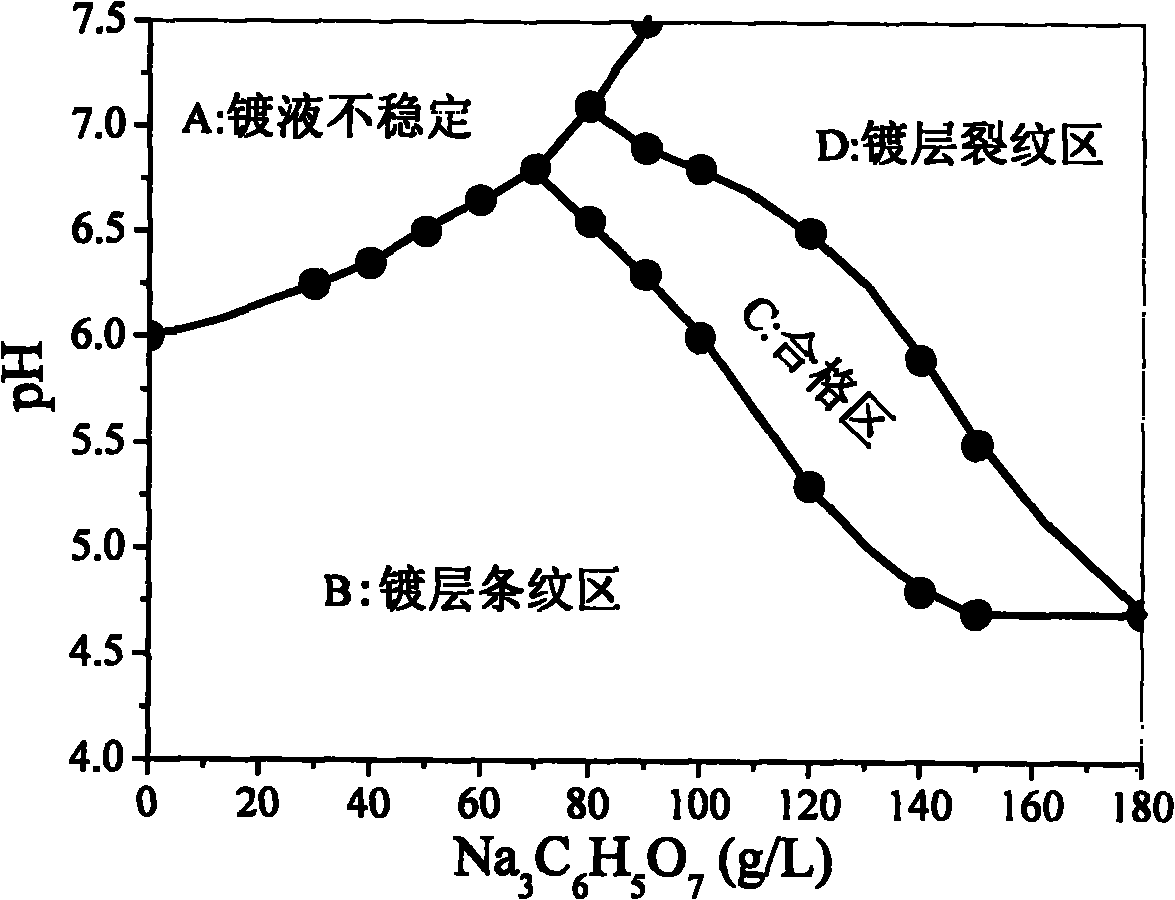

[0056] The above components are prepared according to the aforementioned preparation process to prepare an electrodeposition nickel plating solution; use 10mol / L sodium hydroxide solution to adjust the pH value of the electrodeposition nickel plating solution to 6.9; keep the temperature of the electrodeposition nickel plating solution at 30°C ; Immerse the deformed zinc alloy through degreasing in the electro-deposited nickel plating solution, and set the cathode current density as 0.8 ampere / decimeter 2 , Electrodeposited nickel plating. The surface of the obtained coating has no streaks, no cracks observed under a metallographic microscope, no blistering and peeling phenomenon under thermal shock at ...

Embodiment 2

[0058] Each component and content thereof of the electrodeposition nickel-plating solution of a kind of wrought zinc alloy are as follows:

[0059] Nickel sulfate hexahydrate 120g / L;

[0060] Sodium chloride 10g / L;

[0061] Boric acid 30g / L;

[0062] Sodium citrate 120g / L.

[0063] The above components are prepared according to the aforementioned preparation process to prepare an electrodeposition nickel plating solution; use 10mol / L sodium hydroxide solution to adjust the pH value of the electrodeposition nickel plating solution to 6.0; keep the temperature of the electrodeposition nickel plating solution at 25°C ; Immerse the deformed zinc alloy through degreasing in the electrolytic nickel plating solution, and set the cathode current density as 1.0 ampere / decimeter 2 , Electrodeposited nickel plating. The surface of the obtained coating has no streaks, no cracks observed under a metallographic microscope, no blistering and peeling phenomenon under thermal shock at 150°...

Embodiment 3

[0065] Each component and content thereof of the electrodeposition nickel-plating solution of a kind of wrought zinc alloy are as follows:

[0066] Nickel sulfate hexahydrate 130g / L;

[0067] Sodium chloride 15g / L;

[0068] Boric acid 35g / L;

[0069] Sodium citrate 170g / L.

[0070] The above components are prepared according to the aforementioned preparation process for electro-deposition nickel plating solution; use 10mol / L sodium hydroxide solution to adjust the pH value of the electrodeposition nickel-plating solution to 4.8; keep the temperature of the electrodeposition nickel-plating solution at 20°C ; Immerse the deformed zinc alloy through degreasing in the electro-deposited nickel plating solution, and set the cathode current density as 1.5 ampere / decimeter 2 , Electrodeposited nickel plating. The surface of the obtained coating has no streaks, no cracks observed under a metallographic microscope, no blistering and peeling phenomenon under thermal shock at 150° C., a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com